Automatic inner cylindrical circular seam welding machine with flexible rail

A technology of flexible track and automatic welding machine, applied in the direction of welding accessories, welding rod characteristics, welding equipment, etc., can solve problems such as unusable, limited cantilever telescopic length, etc., to save rework costs, improve welding efficiency and welding quality of weld seams , Improve the effect of weld seam forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

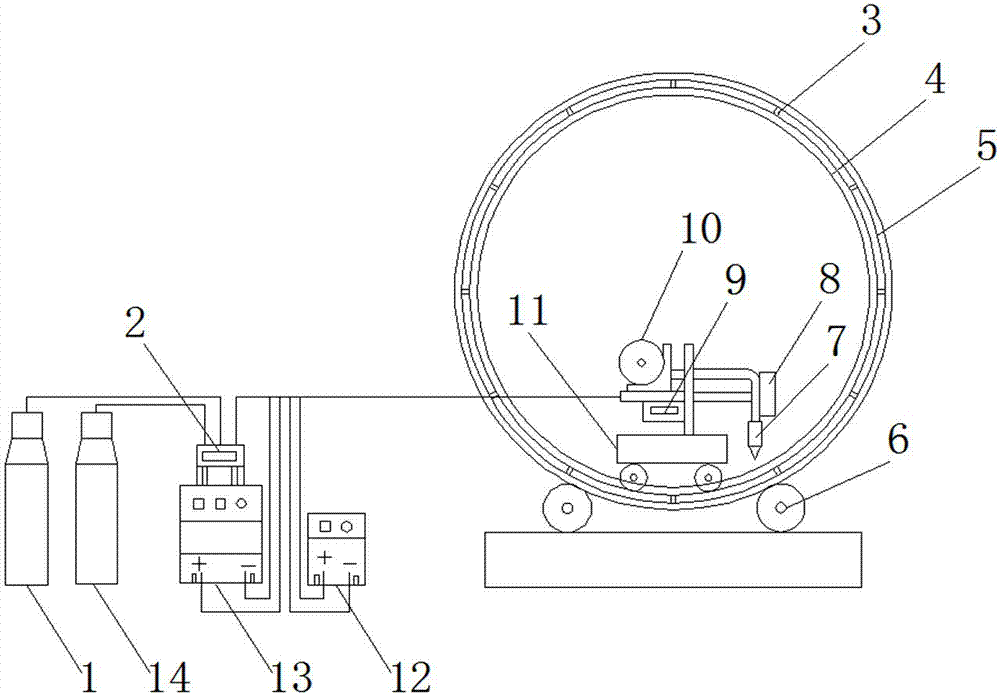

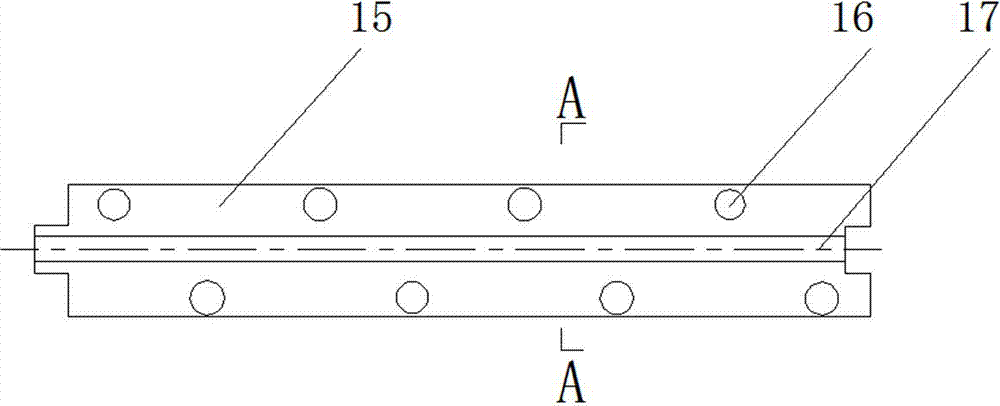

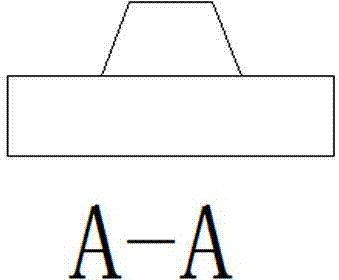

[0014] The present invention is an automatic welder for circular seam inside a cylinder with a flexible track, which includes a main body of the welder, an air supply mechanism, a cooling mechanism, and a rolling mechanism, such as figure 1 shown. The main body of the welding machine includes a welding torch 7, and the front end of the welding torch 7 is provided with an arc-shielding baffle 8, which can prevent the operator from being affected by too strong arc light. The welding torch 7 is connected to the wire feeder 10, the bottom of the wire feeder 10 is provided with a welding oscillator 9, and the main body of the welding machine also includes a speed regulating trolley 11 at the bottom of the wire feeder 10 and the welding oscillator 9 , using the trolley with stepless speed regulation as the carrier, the wire feeder, welding oscillator and welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com