Method for removing pad defect

A pad and defect technology, applied in the field of pad defect removal, can solve the problems of limited defect removal capability, high cost, pad metal damage, etc., to reduce pits defects, reduce pad damage, and save rework costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

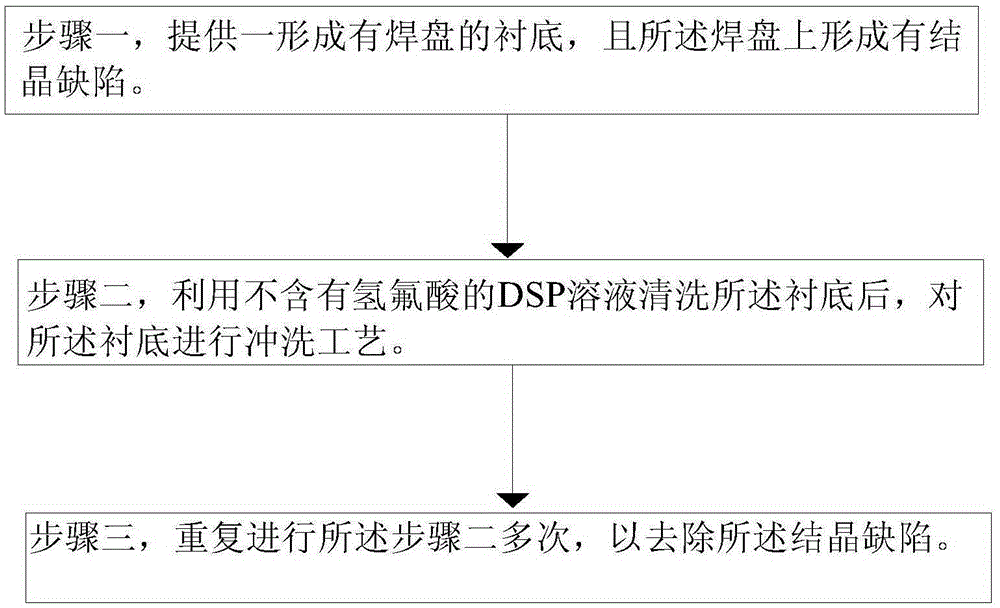

[0024] Such as figure 1 As shown, this embodiment relates to a method for removing pad defects, including:

[0025] Step 1, providing a substrate with pads formed, and crystal defects formed on the pads; since the technology of the substrate with pads can be well known to those skilled in the art, its specific preparation process is in I won't go into details here.

[0026] In a preferred embodiment of the present invention, the pad is an aluminum pad, and correspondingly, the crystal defect is a compound containing fluorine (F), oxygen (O) and aluminum (Al). The mechanism of the crystal defect formation is: the aluminum pad and its oxide react to form aluminum hydroxide in the presence of fluoride ions and water vapor, and then react with H+F- to form the compound containing fluorine, oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com