Drying room with hot air distributed uniformly

A drying room and uniform distribution technology, applied in the field of drying system, can solve the problems of material surface hardening and crusting, dragging down the drying efficiency of materials, uneven distribution of hot air, etc., to achieve uniform temperature and temperature rise, and soft wind speed , good drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

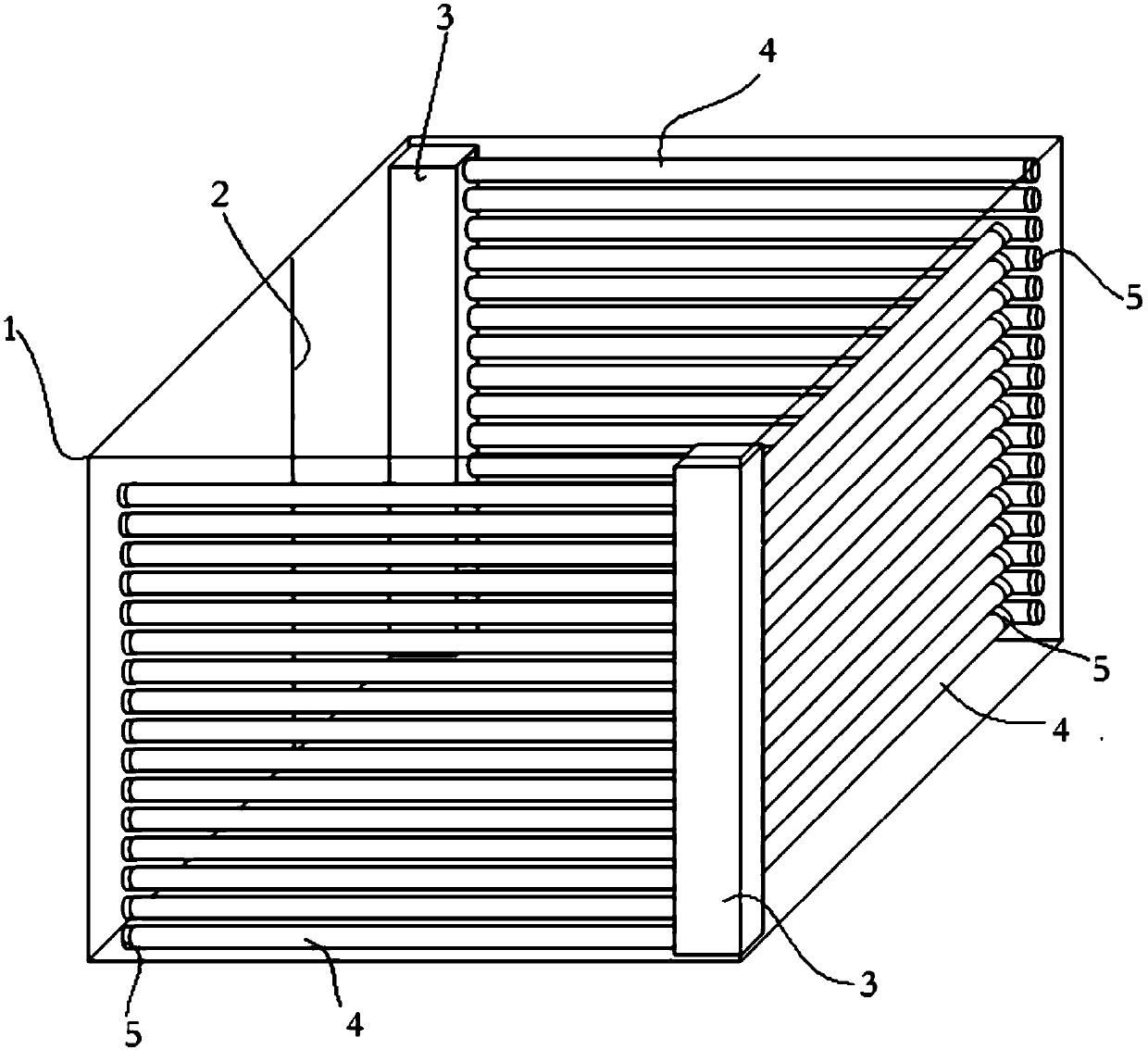

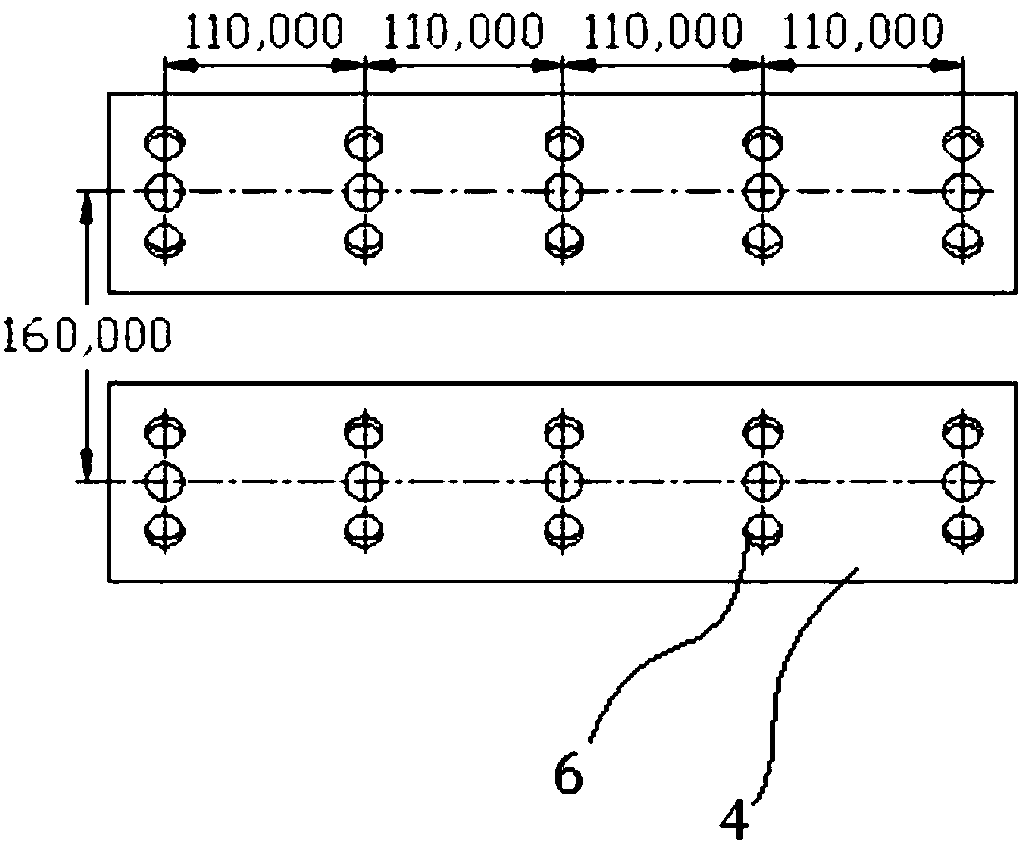

[0013] Referring to the accompanying drawings, reflecting a specific structure of the present invention, the hot air evenly distributed drying room 1 is supplied with drying hot air by a heat source (not shown in the figure). It also includes a number of air ducts 4 evenly distributed on the three sides of the drying room 1. One side of the drying room 1 is provided with a feed door 2, and the position of the side where the feed door 2 is removed can also be provided with an air duct 4 ( For clarity, figure 1 Omit the side air ducts on both sides of the feed door 2).

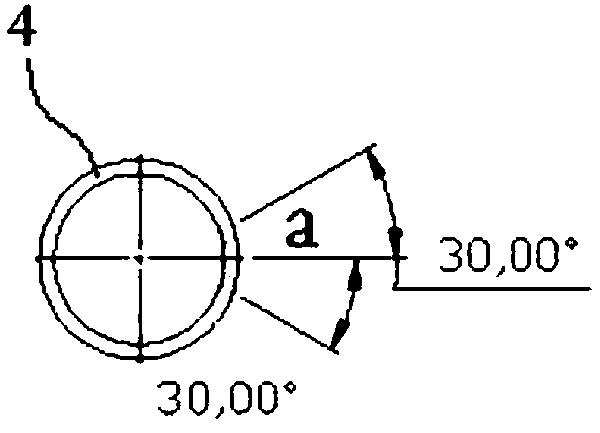

[0014] An air distribution cavity 3 is arranged between the heat source and the air inlet end of the air guide pipe 4 , and the other end of the air guide pipe 4 is closed by a plug 5 . The drying hot air supplied by the heat source enters the air duct 4 through the air distribution chamber 3 . The air guide pipe 4 is arranged on the side close to the drying room 1, and several exhaust holes 6 are uniformly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com