Garbage compacting box garbage scattering-free hopper

A garbage compression and garbage technology, which is applied in garbage conveying, garbage collection, loading/unloading, etc., can solve the problems of dirtying the working environment, generating dust, secondary pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

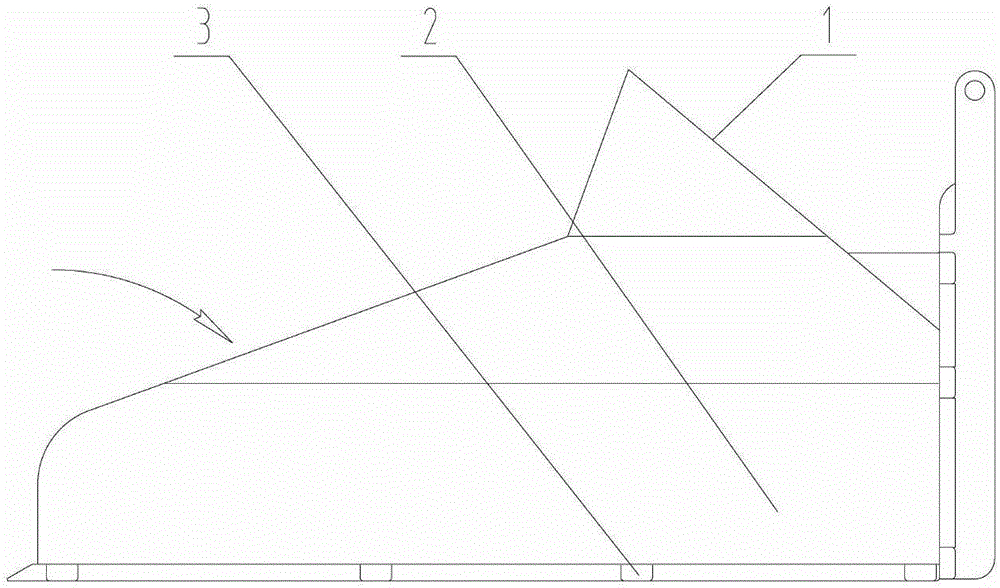

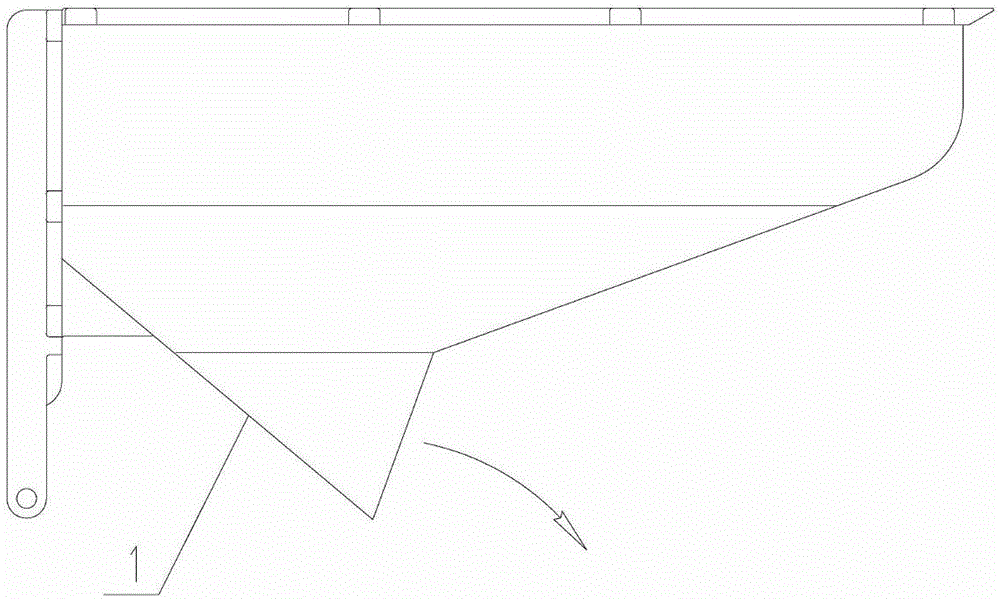

[0018] Embodiment 1: The present invention provides the new style of garbage mobile compression box hopper, and hopper is similar to the dustpan of sweeping rubbish of large size, and usually the back and bottom surface are right-angled, when the large-size dustpan (hopper) of mechanized operation turns over 180 ° Afterwards, the garbage inside will pour down and be thrown into the cabin immediately, generating dust, and some lighter garbage such as paper pieces will be thrown outside, making the environment of the cleaning station dirty, affecting the work of the staff, and prompting the surrounding personnel to return to the cabin. Without a mask. There is an inclined material guide plate on the back of the hopper of the present invention. When the hopper is turned over 180°, the bottom faces the sky, and the garbage at the bottom is at the highest position, and then slides into the material compartment along the inclined material guide plate, the garbage will no longer be th...

Embodiment 2

[0025]Embodiment 2: The present invention uses a timer in the electric control driving part, and the timer is a medium-scale integrated circuit that can be used to replace a mechanical timer, and is named after three 5kΩ resistors are designed at the input end. A timer is a medium-scale integrated device that combines analog and digital functions. The working power supply voltage range of the timer is wide, and it can work normally in the range of 4.5V-16V, and the output driving current is about 200mA, so its output can directly drive a 12V relay. The internal circuit block diagram of the timer and the external pins are arranged,

[0026] The timer includes three voltage comparators, four resistors, a trigger, a power output device, a diode, and an inverter. First, four resistors are connected in series, and two voltage comparators are connected between the four resistors as Series circuit, and then connect the flip-flop and the power output device in series in sequence. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com