Automatic machining production device for automobile brake component and working method thereof

A technology of automobile braking and production equipment, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, and can solve problems such as low product qualification rate, high labor intensity, frequent industrial accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

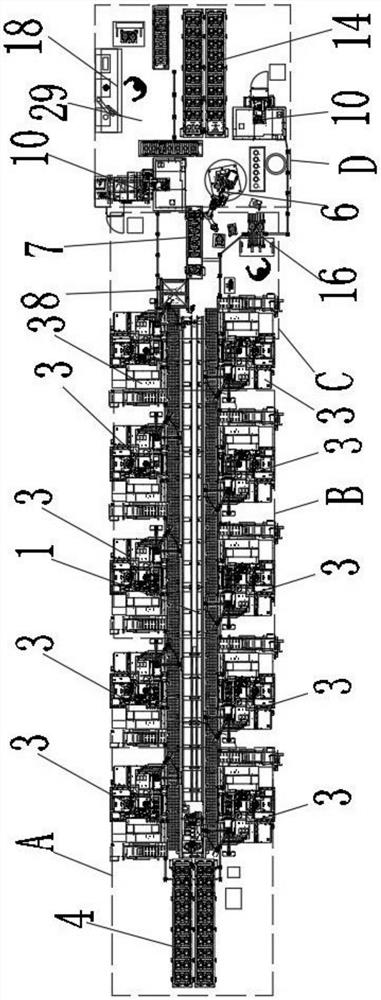

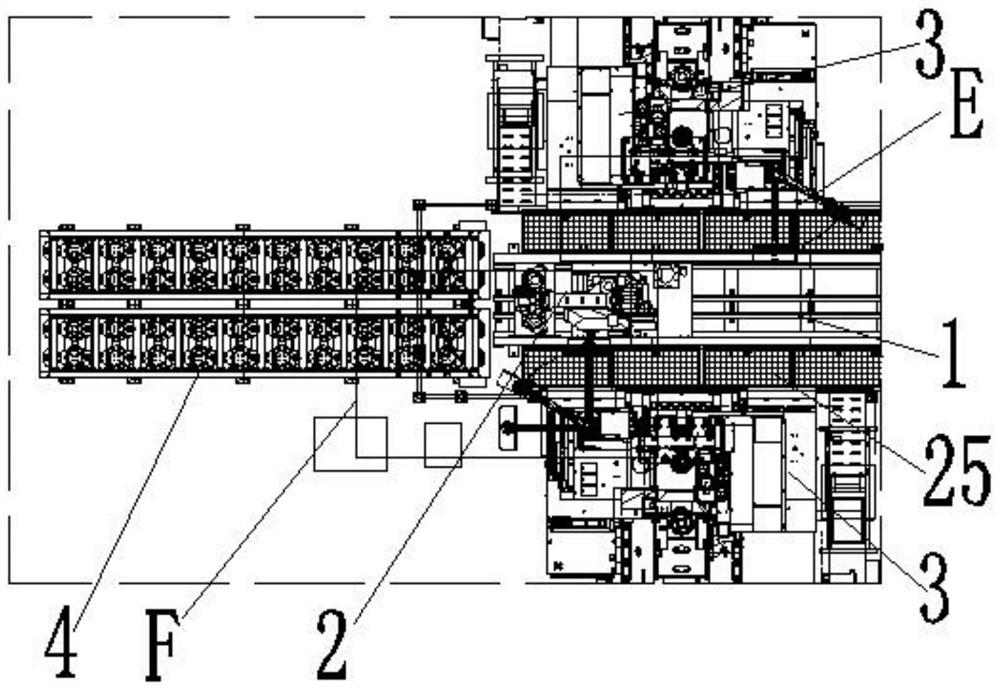

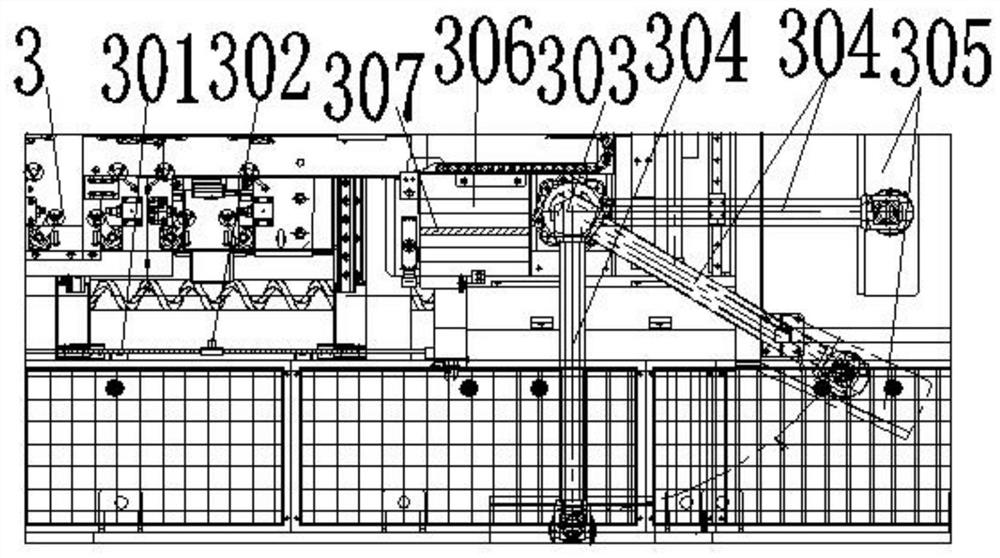

[0075] Example 1. Such as Figure 1-32 As shown, an automatic production device for processing automobile brake parts, the production device includes a horizontally arranged robot walking track 1, a first grabbing mechanism 2, several CNC grinding machine tools 3, a feeding conveyor belt 4, and automobile brake parts Turning table 5, second grabbing mechanism 6, transfer conveyor belt 7, pneumatic debris cleaning table 8, control center 9, two drilling and tapping CNC machine tools 10, filter cutting fluid plate 11, weighing plate 12, coding Machine 13, the first qualified product discharge conveyor belt 14, the unqualified product discharge conveyor belt 15, the sampling turnaround table 16, the detection and analysis platform 17, the manual processing device 18, and the second qualified product discharge conveyor belt 19.

[0076] The robot walking ground rail 1 is provided with a walking base 101 that can move laterally on the robot walking ground rail 1, and the first gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com