Novel shaving board and production method thereof

A production method and particle board technology are applied to the new particle board and its production field, which can solve the problems of not being fireproof, moisture-proof and non-toxic at the same time, and achieve the effects of good density, increased income and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Particleboard with natural fibers as reinforcement.

[0013] Production method 1: ①Material preparation: first process the waste wood into coarse wood powder with a length of 1-30mm and a width of 0.5-3mm for use, and then process it into fine wood powder of 60-100 meshes with shavings or sawdust for use, and purchase it at the same time The viscose agent that magnesium oxide and magnesium chloride are formed is stand-by. Finally, use natural bamboo or rattan to process thin slices, or use this thin slice to weave intertwined bamboo or rattan nets for use.

[0014] ②Seasoning: First mix 45-60% coarse wood powder, 5-10% fine wood powder, and 40-50% adhesive in the mixer to make high-strength layer ingredient A, and then press 40-60% Fine wood powder, 40-60% adhesive, and appropriate amount of pigment are stirred evenly in a mixer to make surface layer ingredient B.

[0015] ③Manufacturing: Spread a layer of 0.1-0.3mm thick surface layer ingredient B on the b...

Embodiment 2

[0017] Embodiment 2: use chemical fiber as the chipboard of reinforcing layer.

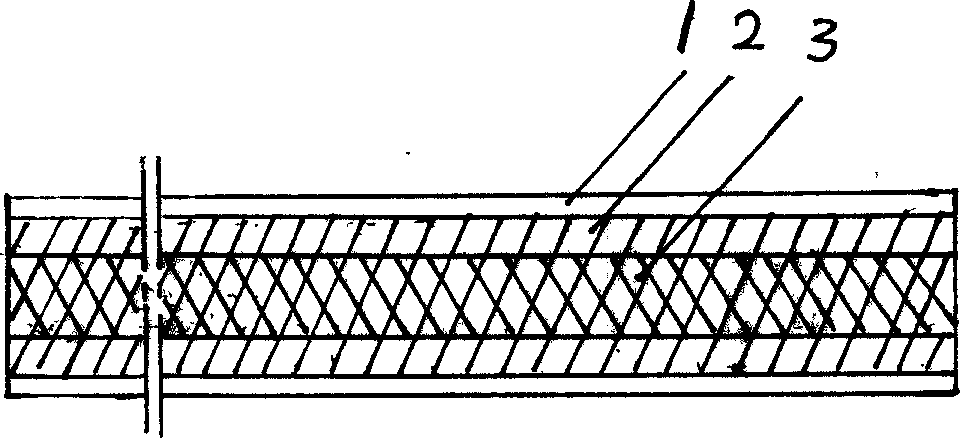

[0018] Production method 2: The production method of this particle board is basically the same as production method 1, except that in the material preparation process, glass fiber or plastic sheets are prepared instead of bamboo and rattan materials. Lay a layer of 1-3mm thick glass fiber or plastic sheet between the high-strength layer in the middle; the particleboard after pressing and forming is the surface layer (1) on both sides, the high-strength layer (3) in the middle, and the surface layer The reinforced layer (2) between (1) and the high-strength layer (3) is made of glass fiber or plastic sheet and viscose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com