Metal-top welding table

a welding table and metal top technology, applied in the direction of variable height tables, soldering devices, auxillary welding devices, etc., can solve the problem of unadjustable flanges, etc., and achieve the effect of increasing flexibility and convenience, easy storage and portability, and increasing the strength of the table top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]With the help of the drawings and the detail description below, the features of the present invention will be apparent and fully understandable.

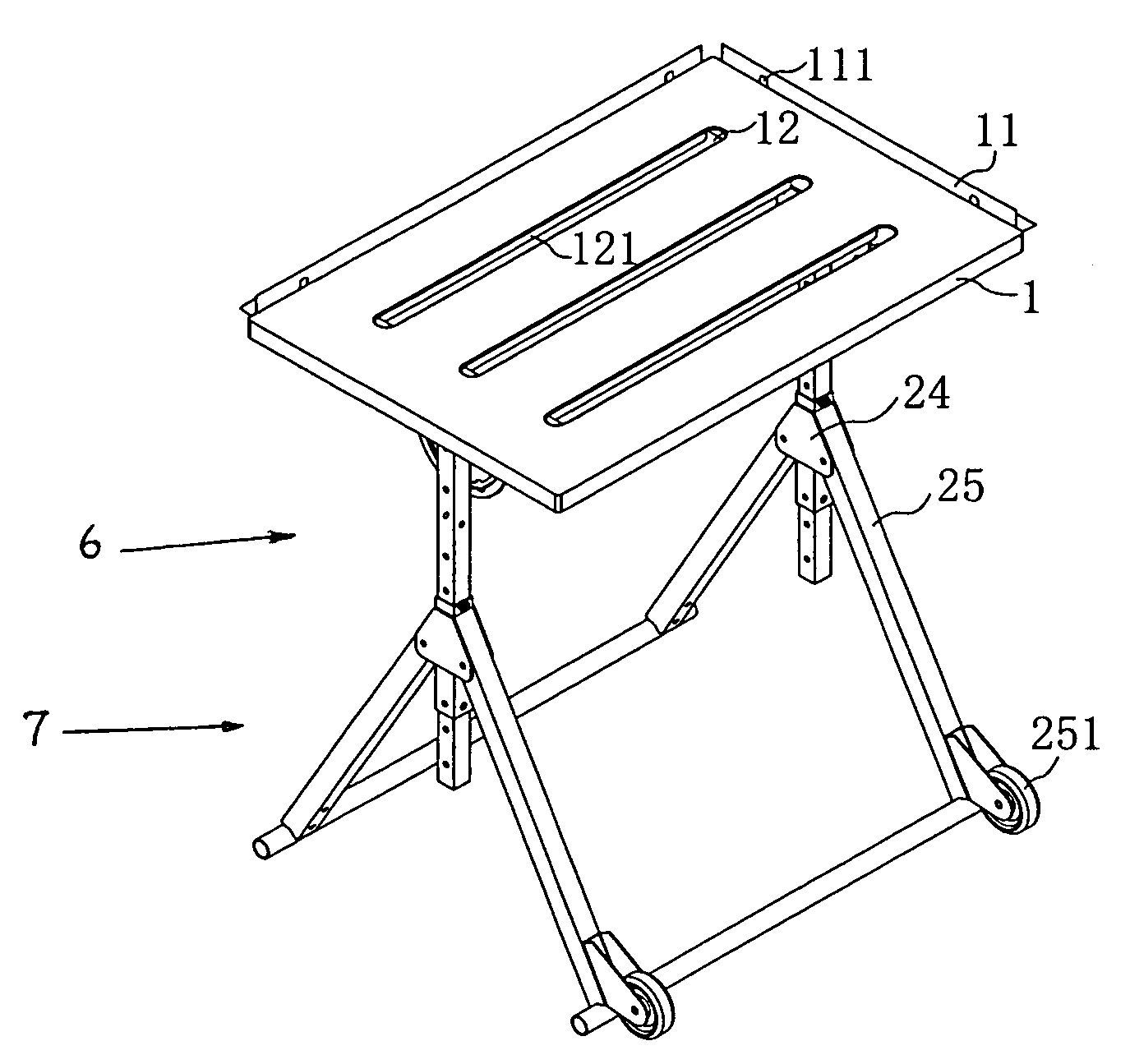

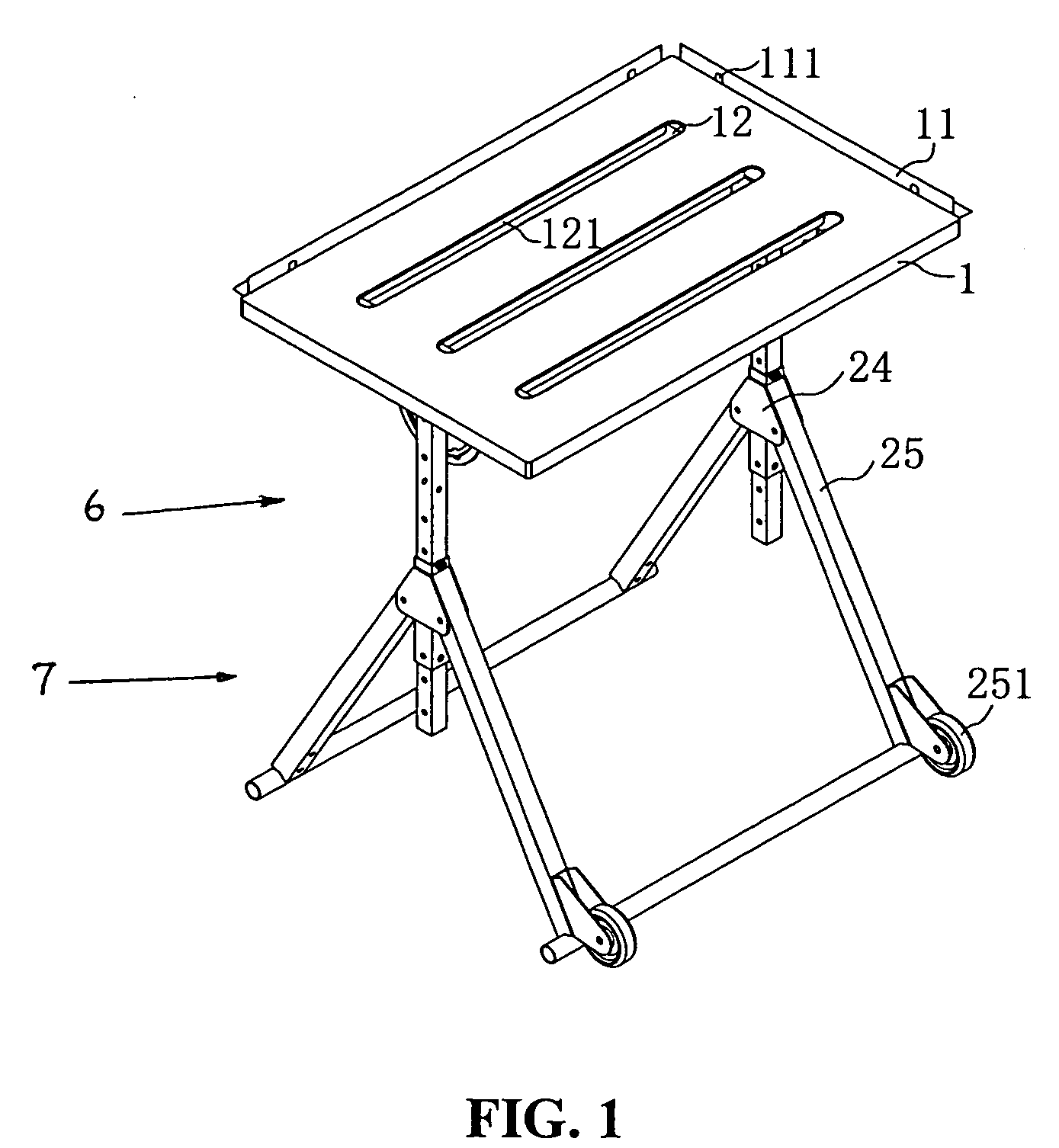

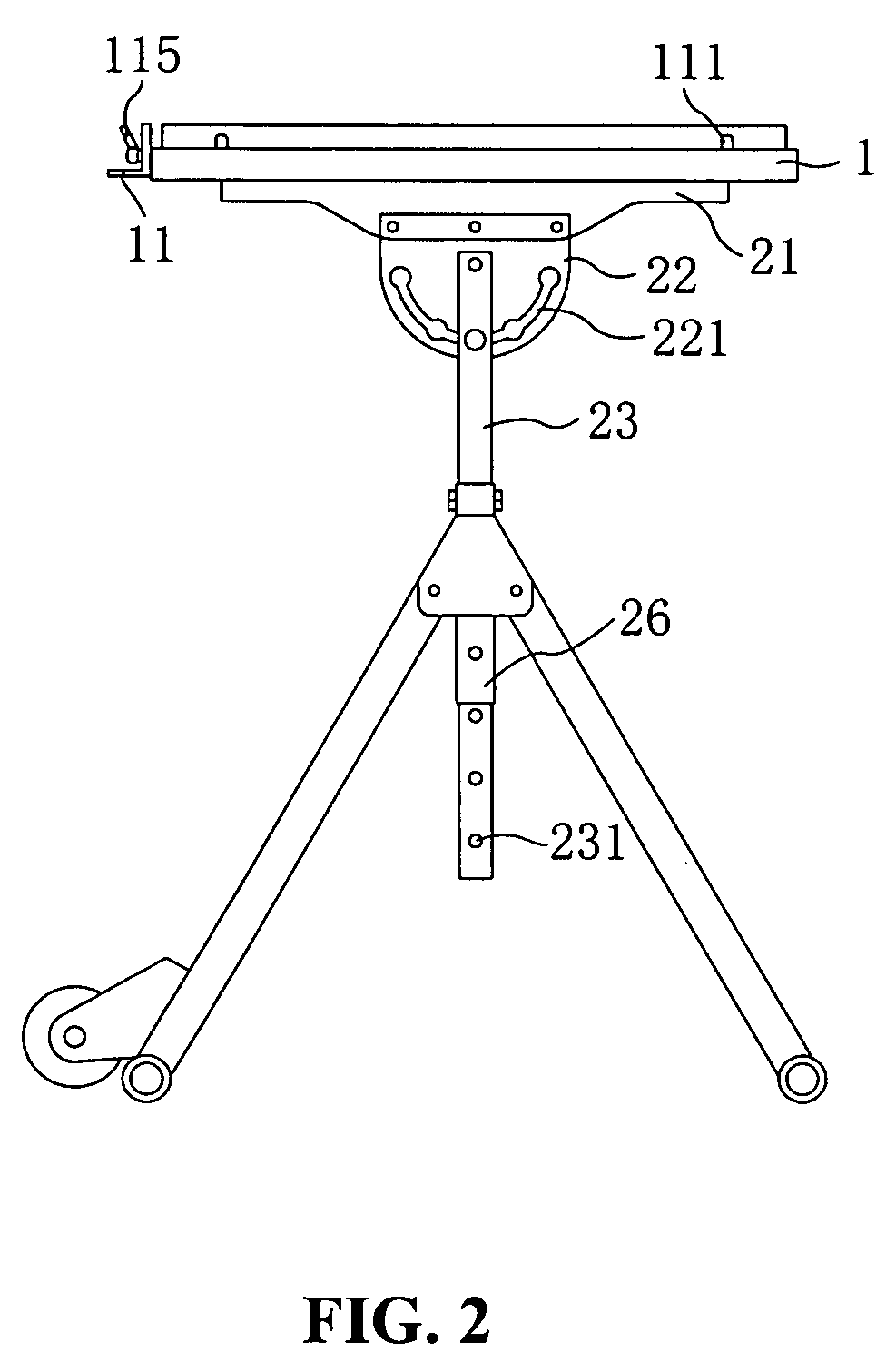

[0020]Referring to FIG. 1, the present invention comprises a rectangular flat table top 1 with protrusion-adjustable angle flange 11 and elongated slots 12, a support structure 6 having an angle and height adjusting mechanism, and a foldable base frame 7 with casters 251.

[0021]Referring to FIG. 7, FIG. 8 and FIG. 9, the flat table top 1 is made of sheet metal for rigidity without adding too much weight on the present invention. At proper location of the flat table top 1, a plurality of elongated slots 12 are equipped for the insertion of clamping tools with cylindrical shanks as well as other types of clamping tools such as C-clamps, bar clamps, etc. Cylindrical tool holes on table top cannot accept C-clamps or bar clamps. The straight edge 121 of each elongated slot is bent downward to a proper depth to form a thickness of the table t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com