Wooden door scribing and cutting integrated machine

An all-in-one machine and wooden door technology, which is applied in the direction of forming/shaping machines, wood processing equipment, special forming/shaping machines, etc., can solve the problems of difficult to guarantee accuracy, troublesome operation, time-consuming and laborious, etc., and achieve high cutting accuracy and improved The effect of processing efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

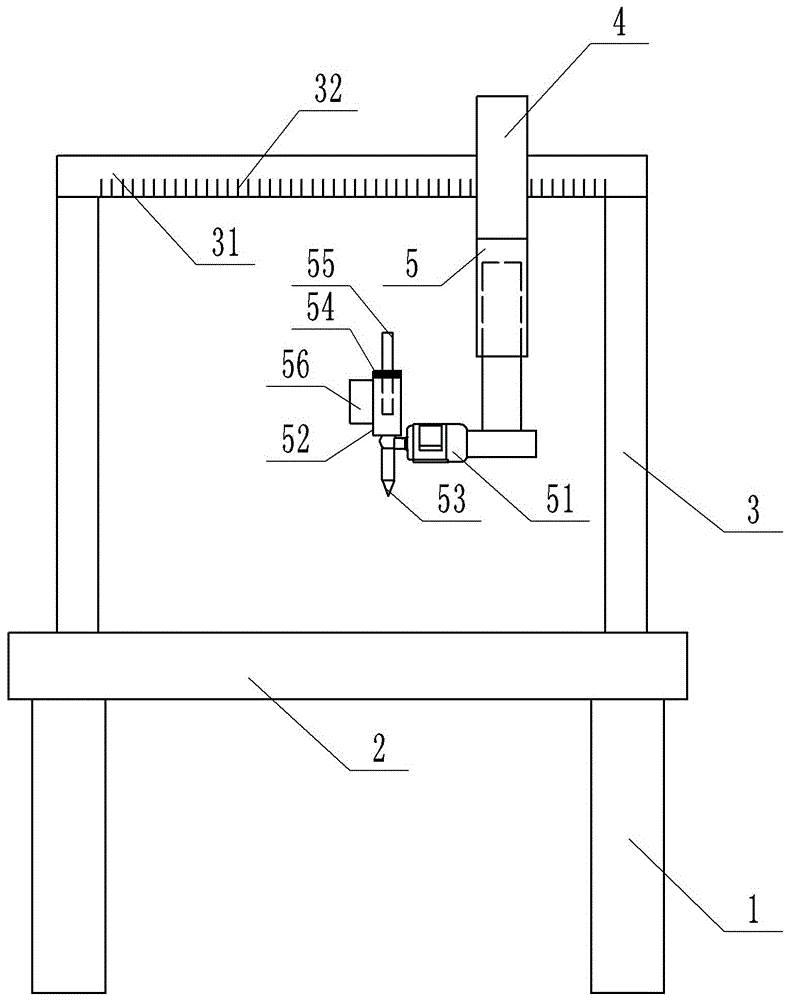

[0014] The reference signs in the accompanying drawings include: support frame 1, workbench 2, moving bracket 3, guide column 31, scale 32, moving rod 4, cylinder 5, servo motor 51, housing 52, marking pen 53, rotating shaft 54, cutting knife 55, motor 56.

[0015] Such as figure 1 As shown, the all-in-one machine for marking and cutting wooden doors includes a support frame 1 and a workbench 2 arranged on the support frame 1. The workbench 2 is provided with a plurality of grooves distributed evenly in the longitudinal direction, and the bottom of the grooves is provided with grooves. Matching baffles that can move up and down; both ends of the workbench 2 are provided with longitudinally distributed chutes, the chute is provided with a movable clamping plate, and the movable clamping plate is provided with positioning pins, and the movable clamping plate can Move on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com