Caving coal mining roadway grouting anchor cable supporting structure and advanced supporting method thereof

A technology for top coal caving, grouting, and grouting anchor cables is used in mining equipment, earthwork drilling, and bolt installation. It can solve problems such as low construction efficiency, high support costs, and high labor intensity. and bearing capacity, good impermeability, and the effect of improving lithology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

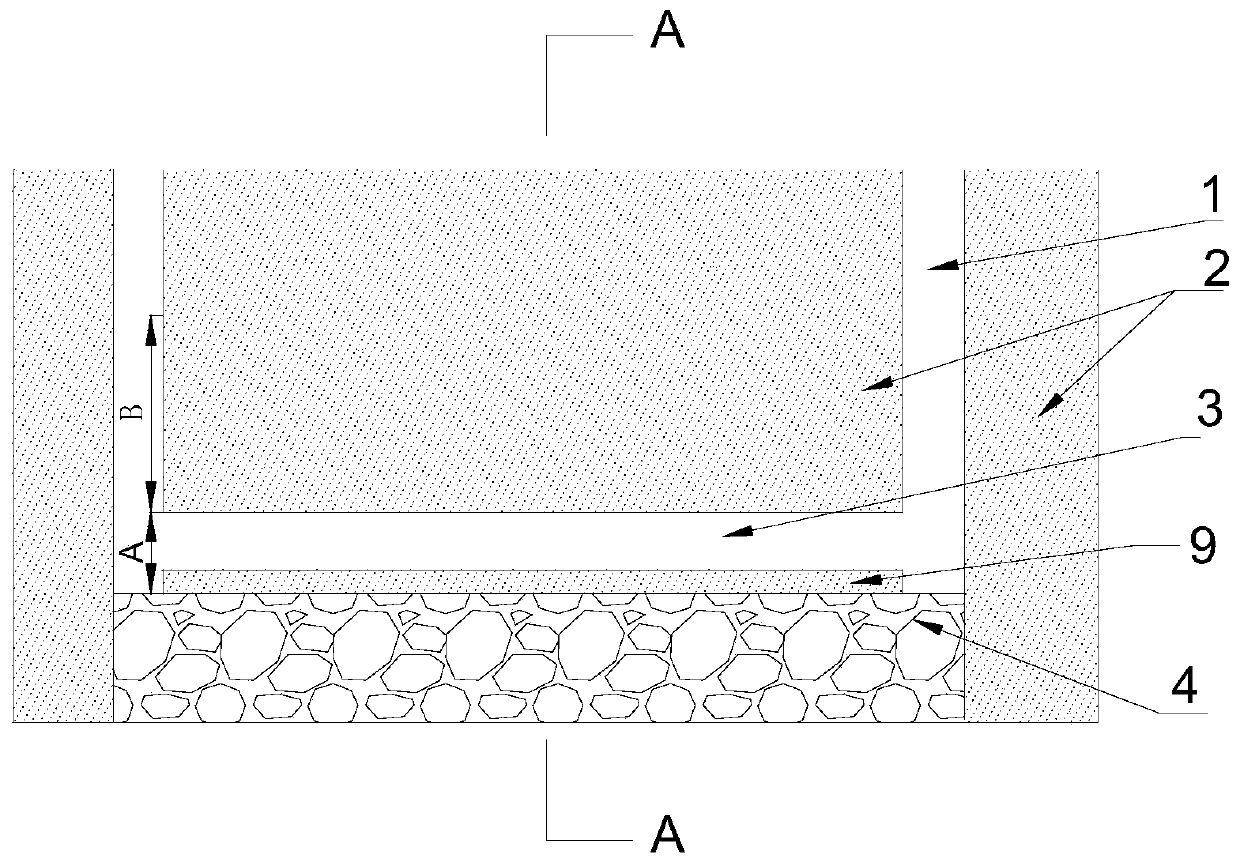

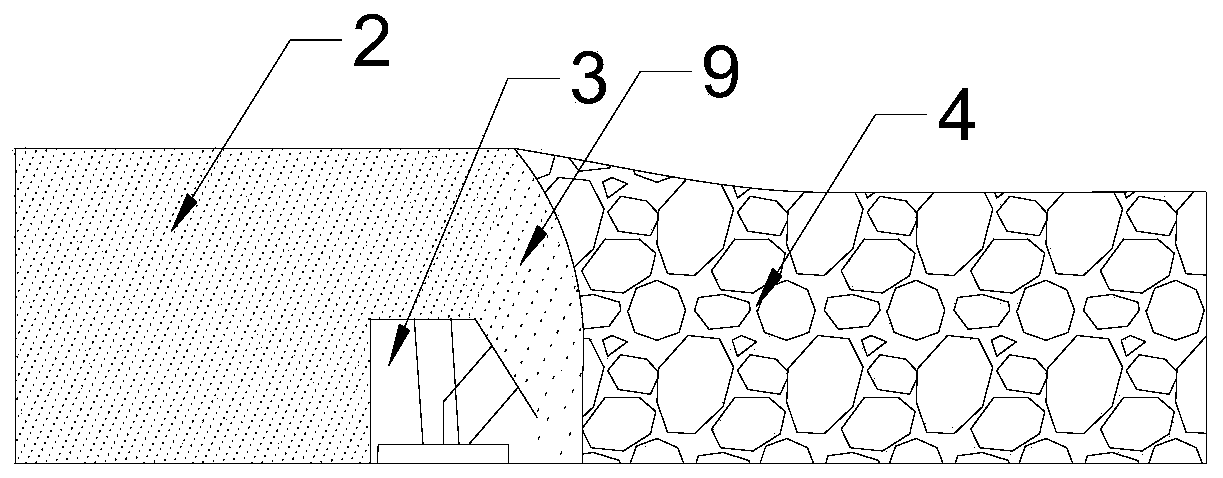

[0026] figure 1 , 2 Shows the positional relationship between mining roadway 1, coal rock mass 2, mining working face 3, goaf 4, and top-coal caving 9. While coal mining operation is being carried out at mining working face 3, the work of mining roadway 1 Advance support is carried out in the face end area A and the advanced support area B of the mining roadway, that is, the advanced support of the grouting anchor cable is carried out within the support distance range of the advanced support of the mining roadway 1.

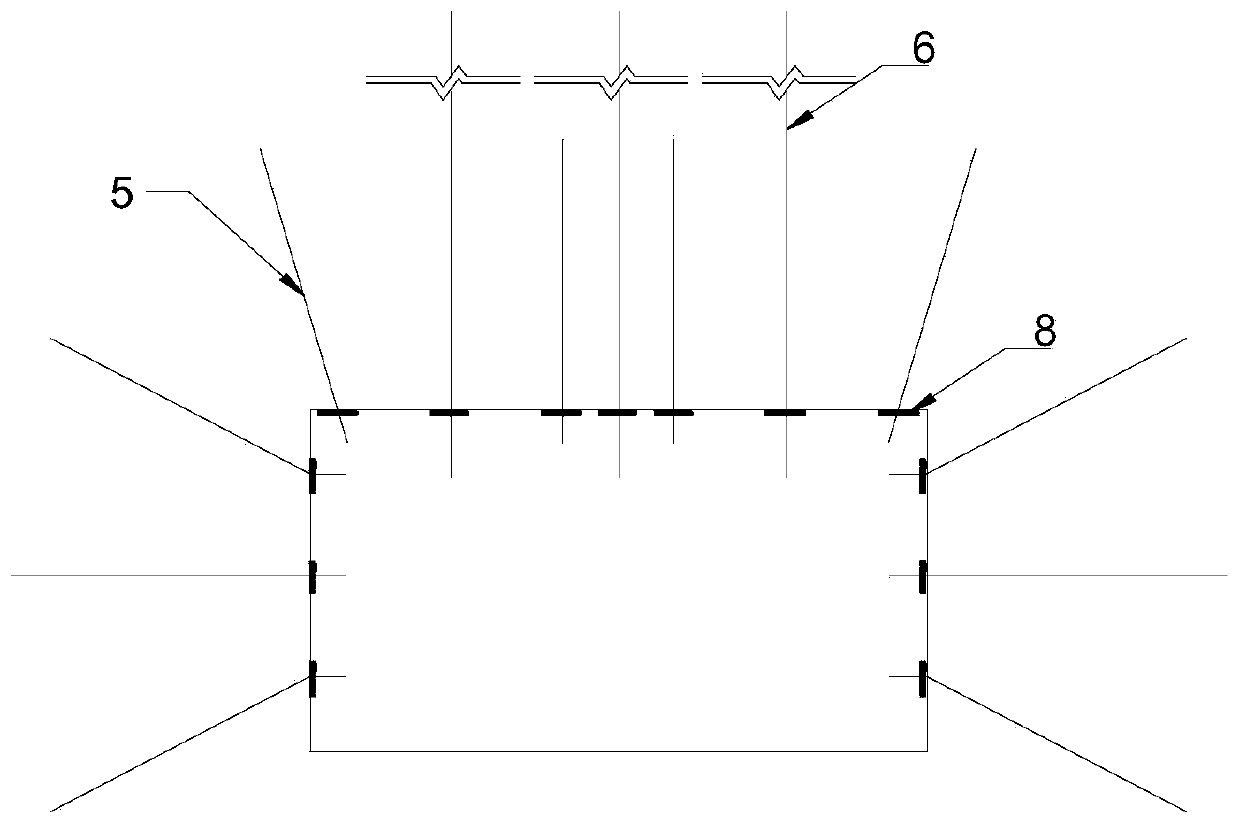

[0027] Such as image 3 , 4 As shown, the first specific embodiment of the grouting and anchor cable support structure of the top-coal caving mining roadway is to set up permanent supports on the top plate and both sides of the mining roadway 1. The permanent support was carried out in the process of mining, and the advance support of the mining roadway was carried out on the basis of the original permanent support during the mining process of the working face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com