Nanometer inorganic carbonized wood preparation method, nanometer inorganic carbonized wood products and application of nanometer inorganic carbonized wood

A nano-inorganic, carbonized wood technology, applied in the field of wood processing, can solve the problems of not easy to clean, easy to fall off of carbon powder, strength and surface hardness decrease, etc., to solve the problem of fiber channel and adsorption capacity decrease, corrosion resistance and good hydrophobicity , Improve the effect of strength and hardness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

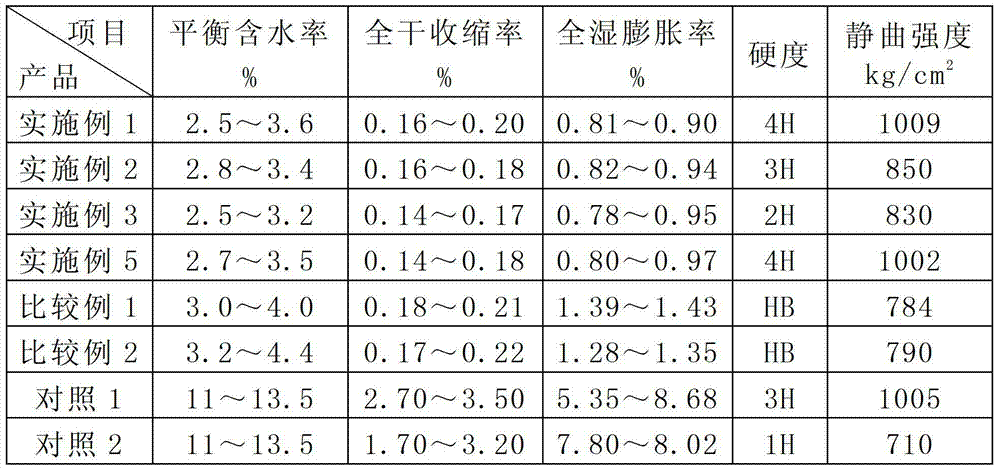

Examples

Embodiment 1

[0030] Oak is used as the material, and the oak is arranged into the corresponding length, width and thickness (such as length 800mm x width 100mm x thickness 25mm) of wood boards (solid wood boards) according to the requirements of the product, and then stacked outside the carbonization kiln according to the conventional method. In order to further prevent the end surface of wood panels (solid wood panels) from cracking during the carbonization process, thick paint (such as undiluted high-temperature blended paint or anti-embroidery paint, etc.) to cover all end faces;

[0031] Deep carbonization treatment: first put the above-mentioned stacked wood boards (solid wood boards) into the carbonization kiln, close the feed port, and then turn on the heat source, so that the temperature in the carbonization kiln is raised for the first time at a heating rate of 10°C / h to 95°C, do not spray steam at intermittent points during the heating period, keep warm and dry for 2 to 4 hours, ...

Embodiment 2

[0036] Using big-leaf poplar as raw material, arrange the big-leaf poplar into wood boards (solid wood boards) with corresponding length, width and thickness (such as length 800mm x width 100mm x thickness 25mm) according to the product requirements, and then carbonize according to the conventional method For stacking outside the kiln, in order to prevent wood panels (solid wood panels) from cracking during the carbonization process, thick paint (such as undiluted high-temperature blended paint or anti-embroidery paint, etc.) with high temperature resistance (above 300°C) can be used Brushing on the end face to cover the entire end face;

[0037] Deep carbonization treatment: first put the above-mentioned stacked wood boards (solid wood boards) into the carbonization kiln, close the feed port, and then turn on the heat source, so that the temperature in the carbonization kiln is raised for the first time at a heating rate of 15°C / h to 110°C, do not spray steam at intermittent ...

Embodiment 3

[0041] Using big-leaf poplar as raw material, the big-leaf poplar is sorted into wood panels (solid wood panels) with corresponding length, width and thickness (such as length 800mm x width 100mm x thickness 25mm) according to product requirements. The wood panels (solid wood panels) ) with a moisture content of ≤13%, and then stack them outside the carbonization kiln according to conventional methods. High-temperature blended paint or anti-embroidery paint, etc.) evenly brush on the end face to cover all end faces;

[0042]Deep carbonization treatment: first put the above-mentioned stacked wood boards (solid wood boards) into the carbonization kiln, close the feed port, and then turn on the heat source, so that the temperature in the carbonization kiln is raised for the first time at a heating rate of 10°C / h To 100°C, do not spray steam at intermittent points during the heating period, heat preservation and drying for 3 hours, after the heat preservation is over; then, carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com