Bamboo breaking equipment easy to operate

An easy-to-operate, bamboo-breaking technology, which is applied in mechanical equipment, wood splitting devices, wood processing appliances, etc., can solve problems such as low work efficiency and high labor intensity, and achieve the effects of reducing labor costs, improving work efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

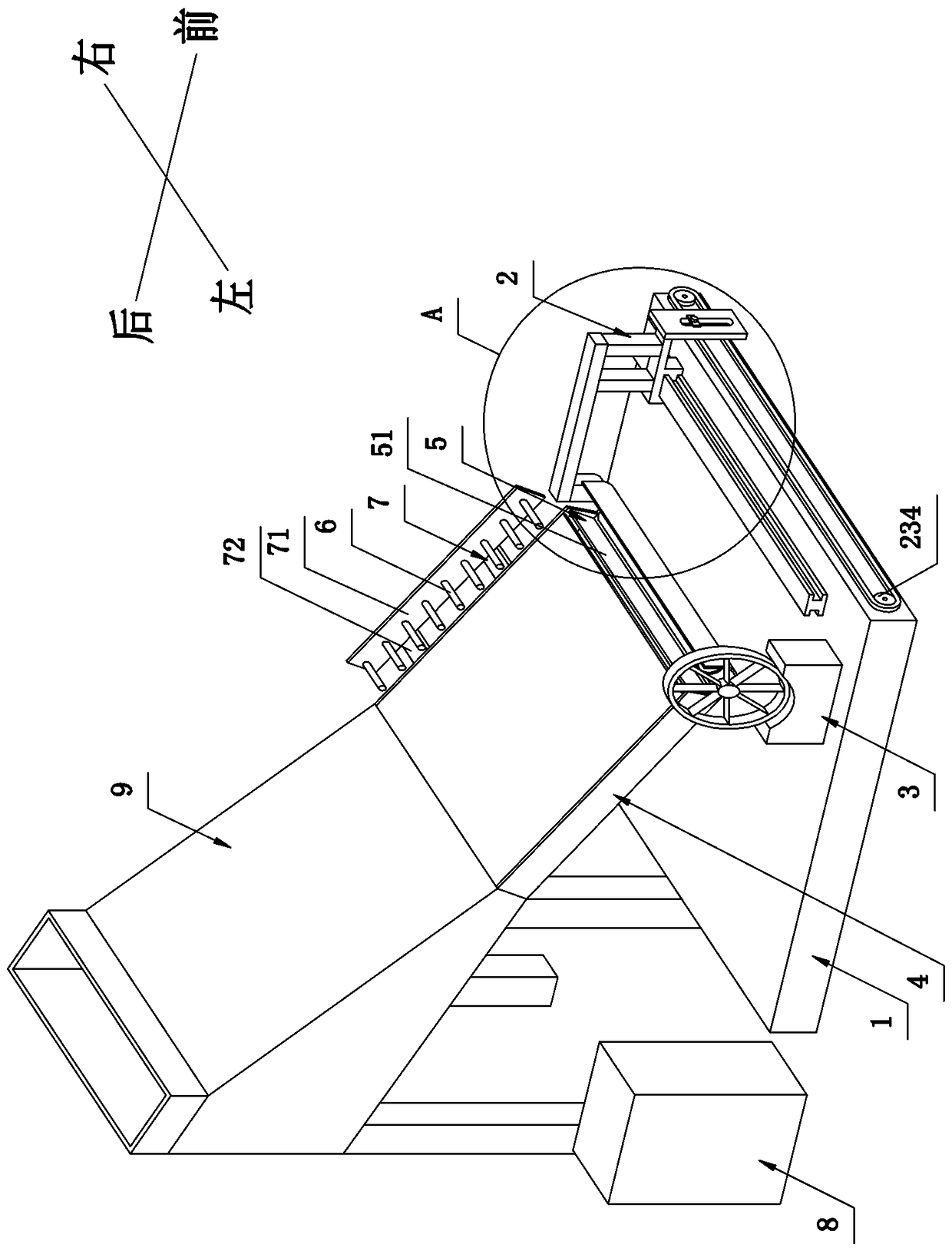

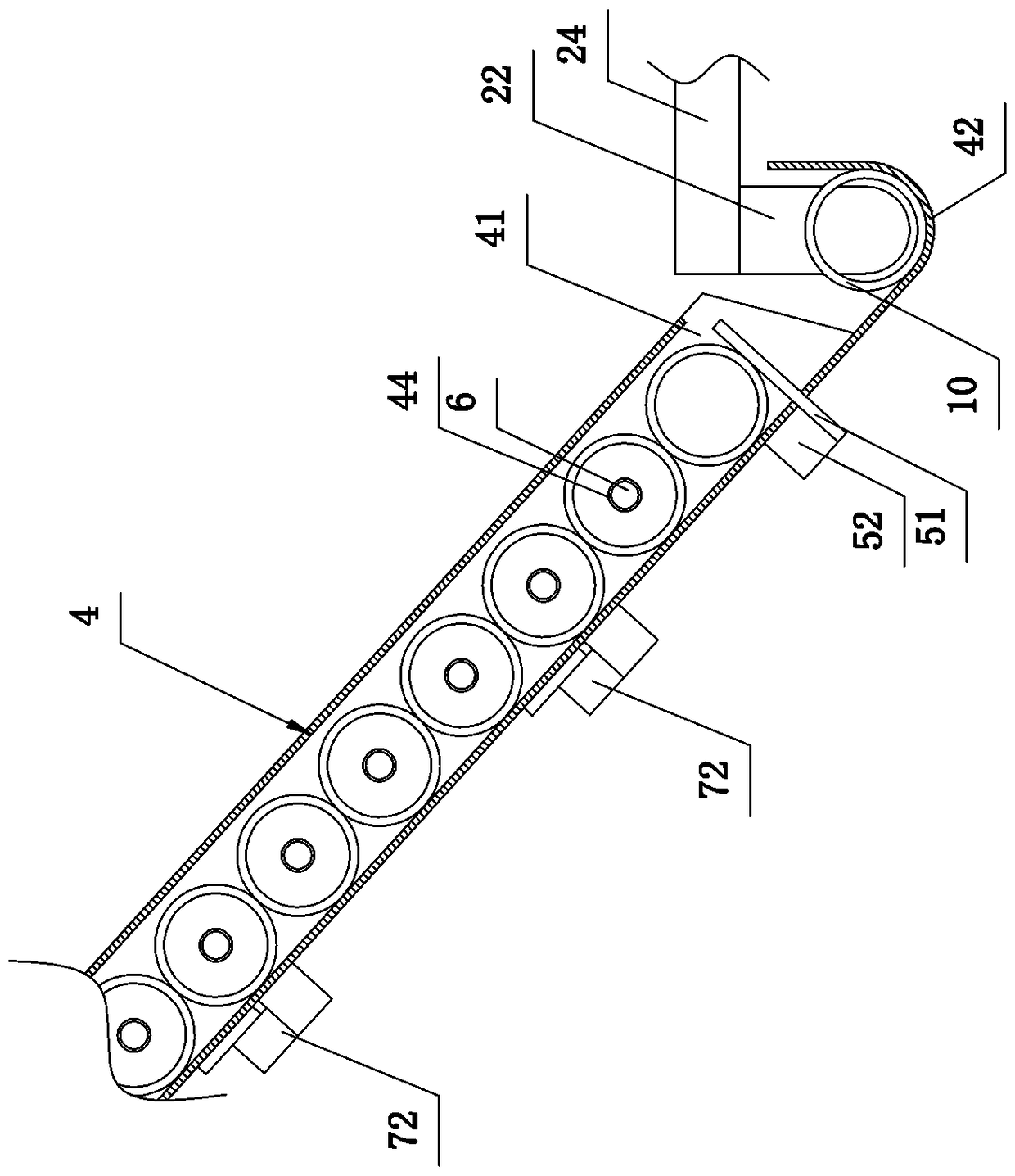

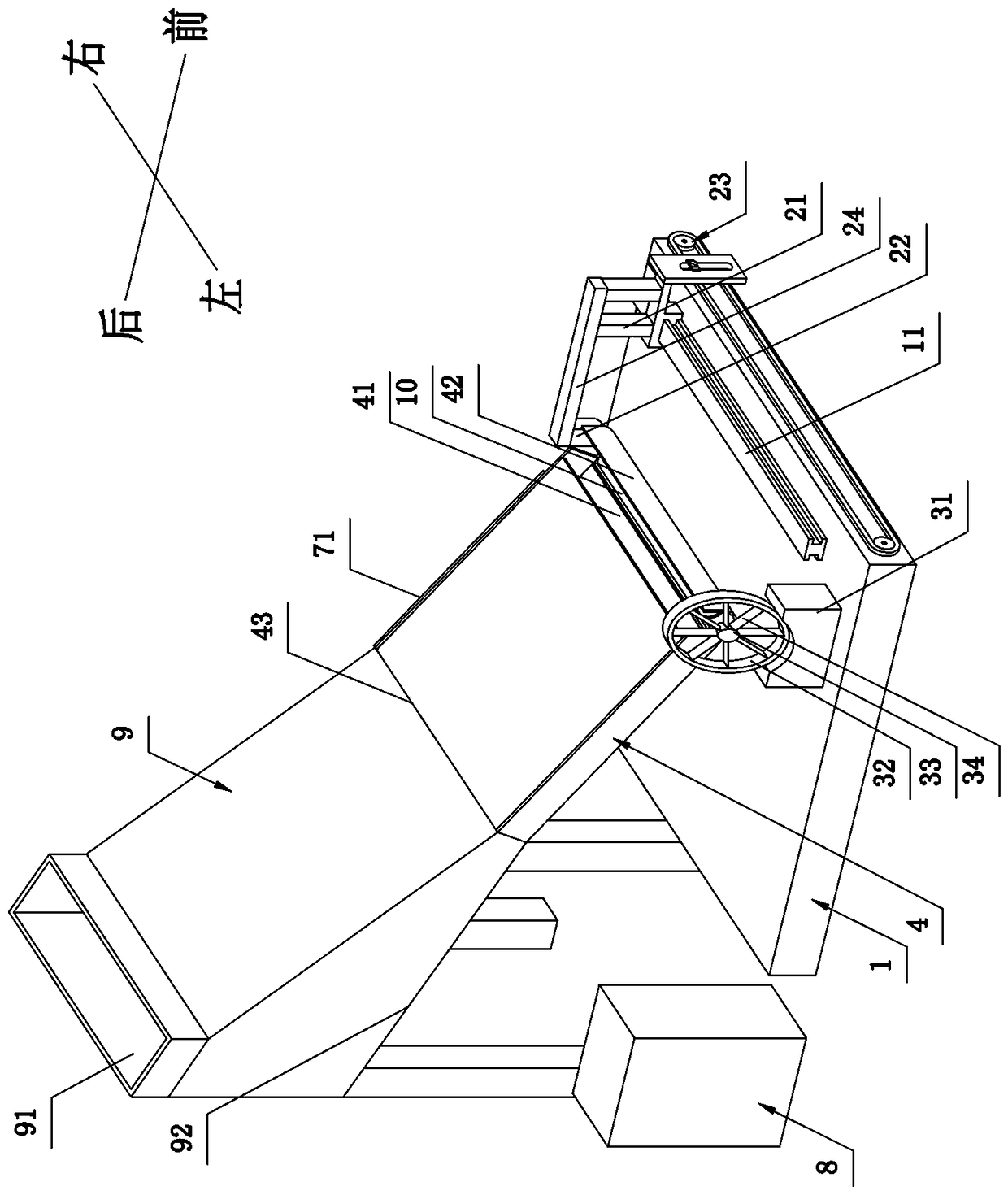

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 . A kind of easy-to-operate broken bamboo equipment, comprising

[0032] Rack 1;

[0033] Bamboo pushing mechanism 2, which is installed on the upper side of frame 1;

[0034] The opening mechanism 3 is installed on the upper side of the frame 1 and is opposite to the bamboo pushing mechanism 2;

[0035] Bamboo rolling chamber 4, which is arranged obliquely along the front-to-back direction and has a plurality of bamboos 10 arranged successively inside, the lower opening 41 of the bamboo rolling chamber 4 extends to connect with a bamboo accommodating groove 42, and the bamboo pushing mechanism 2 can push the bamboo The bamboo 10 in the accommodating groove 42 is pushed to the opening mechanism 3 for cutting; in this embodiment, the inner peripheral surface of the bamboo ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com