Automatic bamboo breaking machine

A bamboo breaking machine and bamboo breaking technology, which is applied in the direction of manufacturing tools, wood splitting devices, wood processing utensils, etc., can solve the problems of easy cutting, low degree of automation, unreliable positioning of bamboo tubes, etc., to achieve high degree of automation and improve production efficiency. , positioning and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

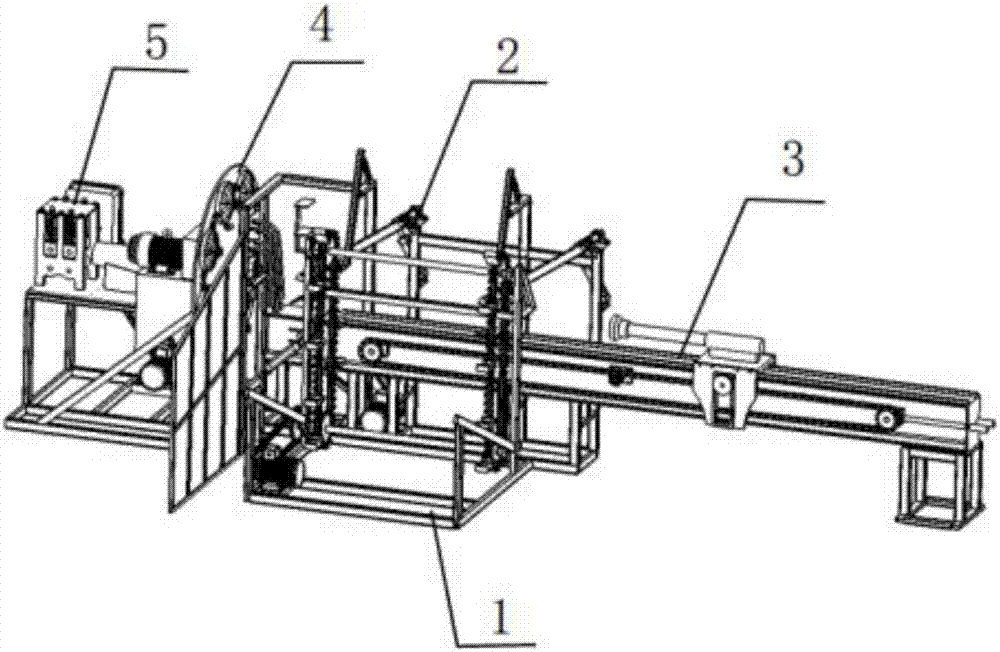

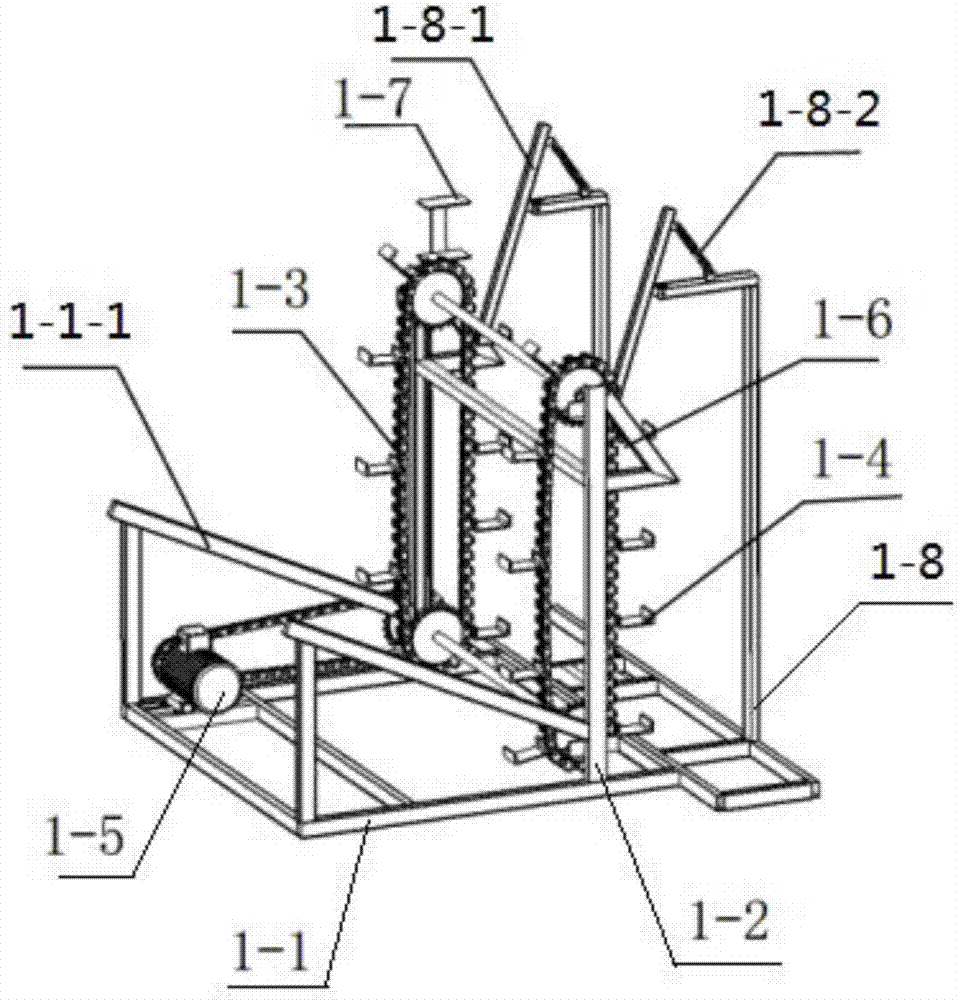

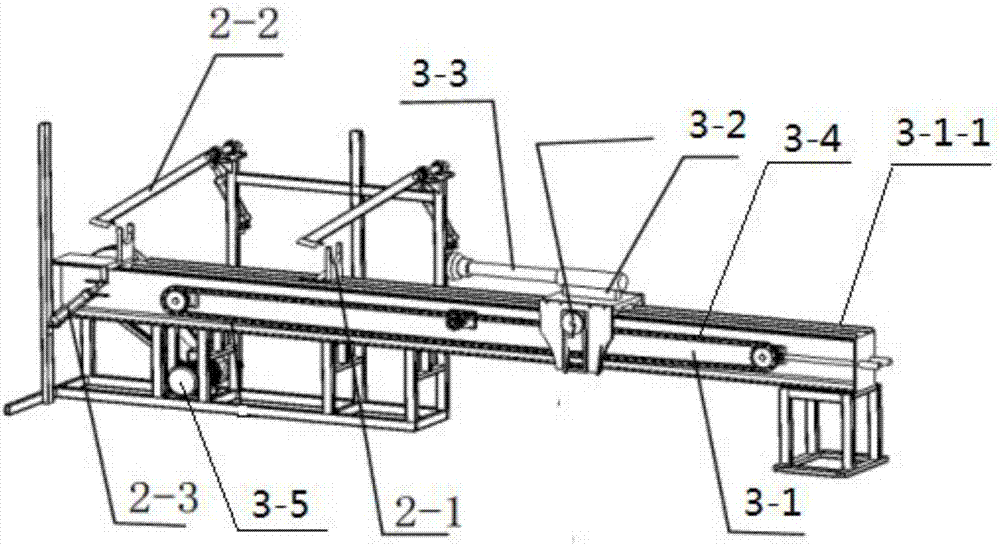

[0046] Such as figure 1 Shown, a kind of automatic bamboo breaking machine comprises feeding device 1, clamping and positioning device 2, broken bamboo pushing plate device 3, tool rotating disk device 4, output device 5 and control system, described feeding device 1 and described clamping and positioning device 2 are respectively located on both sides of one end of the broken bamboo pusher device 3, and the knife turntable device 4 is located at the front part of the broken bamboo pusher device 3 near the end of the feeding device 1 and the clamping and positioning device 2, so The output device 5 is located at the tail of the tool carousel device 4; the control system first controls the clamping and positioning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com