Rotary type plasma removing system for flash butt welding seam burrs outside pipes

A technology of flash butt welding and plasma, which is applied in the direction of plasma welding equipment, welding equipment, welding equipment, etc., can solve the problems of high labor intensity, high cost, and low efficiency of workers, and achieve good equipment flexibility, safe and convenient use, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

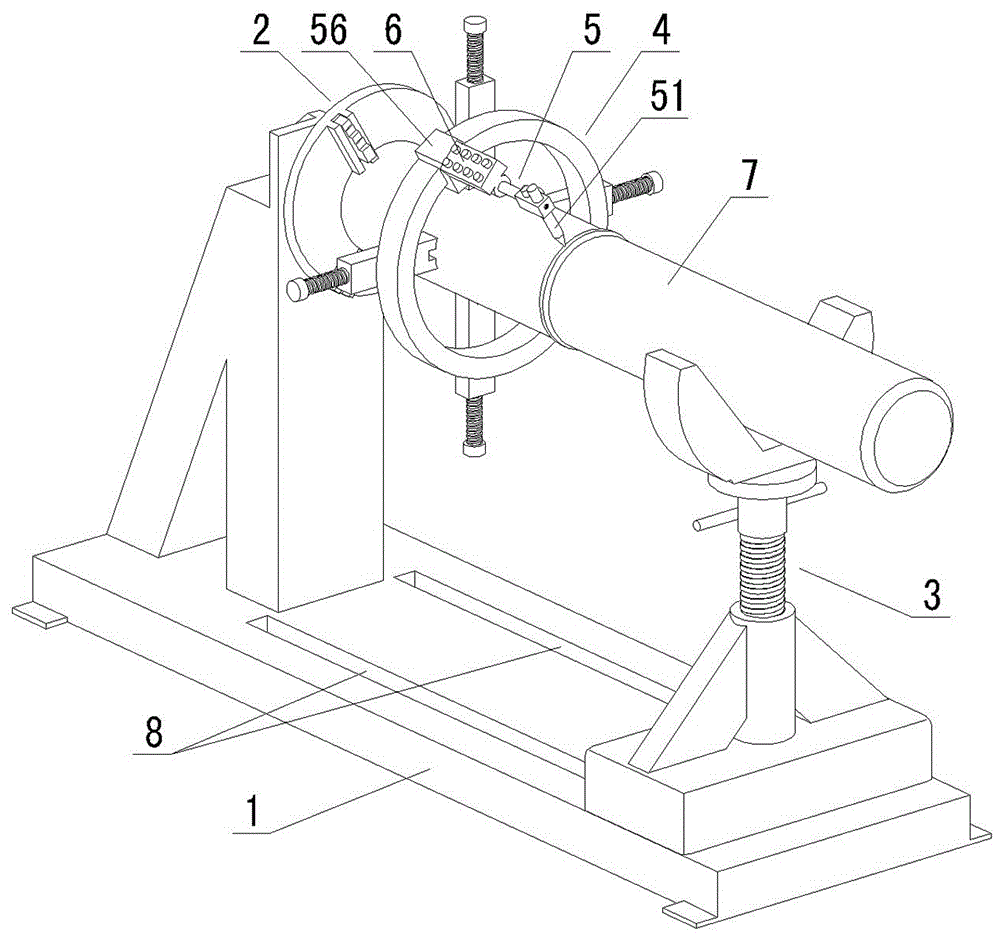

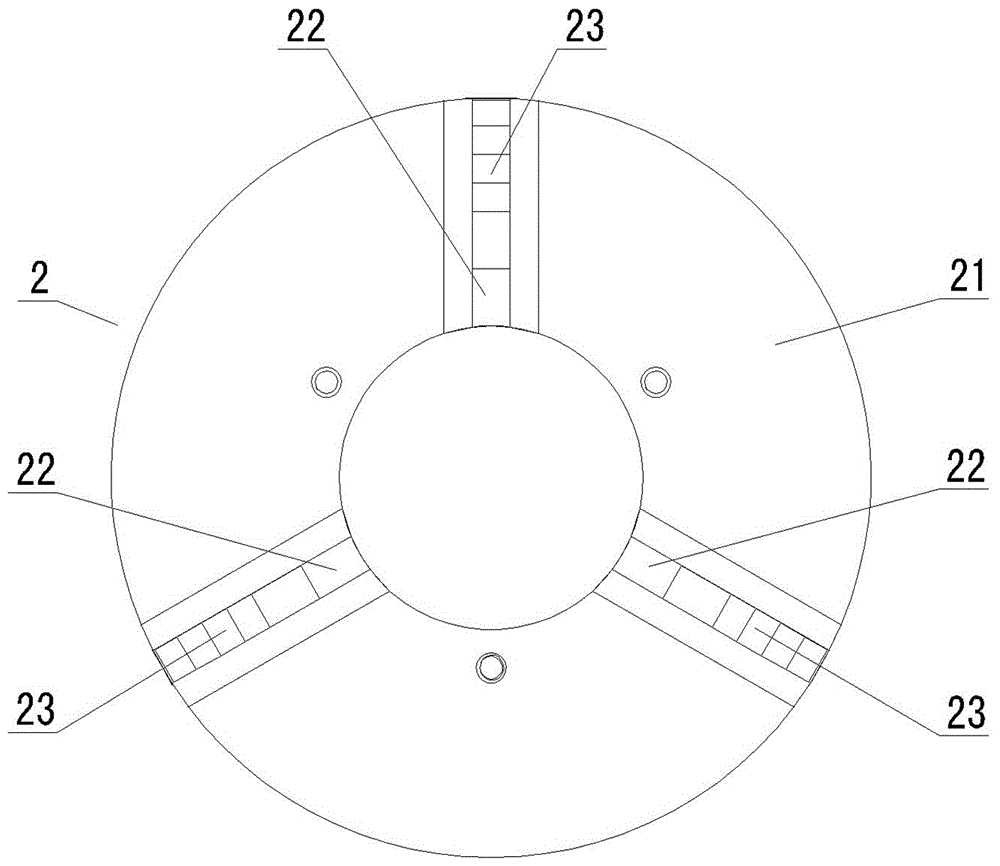

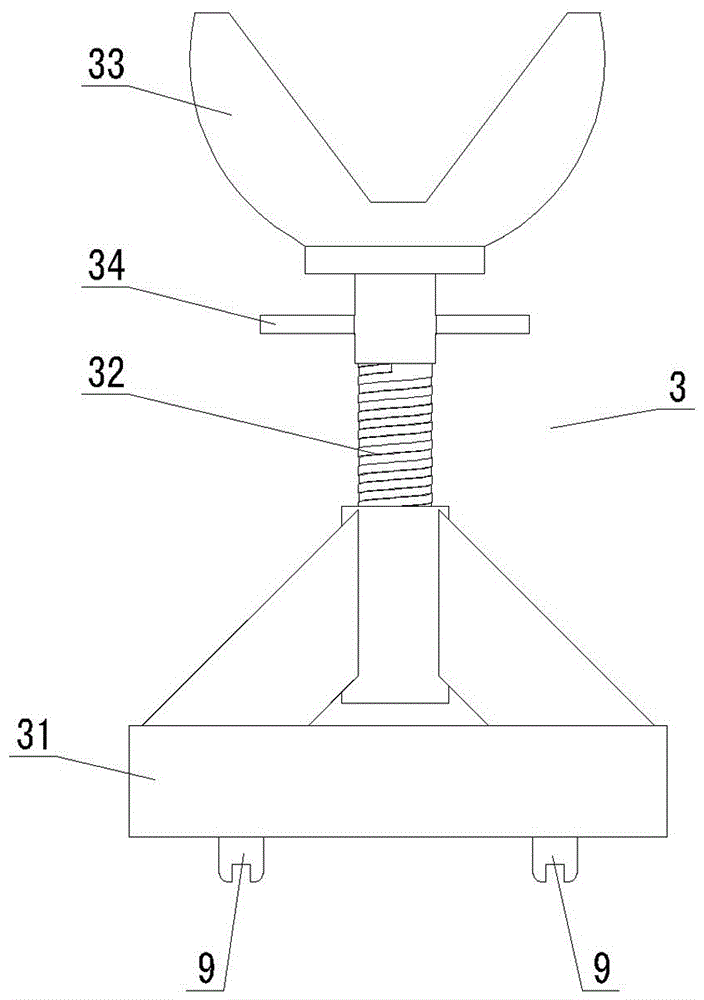

[0024] Such as Figure 1-Figure 6 As shown, the external flash butt welding welding seam rotary plasma removal system of the present invention includes a base 1, a pipe clamping mechanism 2, a pipe support frame 3, a ring track mechanism 4, a plasma gouging gun mechanism 5 and a control System 6, wherein the pipe clamping mechanism 2 and the pipe support frame 3 are both arranged on the base 1, and while one end of the pipe 7 is clamped by the pipe clamping mechanism 2, the pipe 7 is clamped by the pipe support frame 3 The other end of the ring track mechanism 4 is used to be sleeved on the pipeline 7 and connected and fixed with the pipeline 7. The plasma gouging gun mechanism 5 is connected to the ring track mechanism 4 and can be used as a Circular movement is used for plasma removal of weld burr and heat treatment of weld seam. The control system 6 is connected with the plasma gouging gun mechanism 5 to control the work of the plasma gouging gun mechanism 5. The base 1 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com