Equipment for extruding plastic panel with continuously variable cross-section

A technology of plastic sheet and extrusion equipment, which is applied to flat products, household utensils, and other household utensils. It can solve the problems of waste of plastic materials, poor flexibility of equipment, and uniform thickness of the sheet, so as to reduce production costs and achieve good equipment flexibility. The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

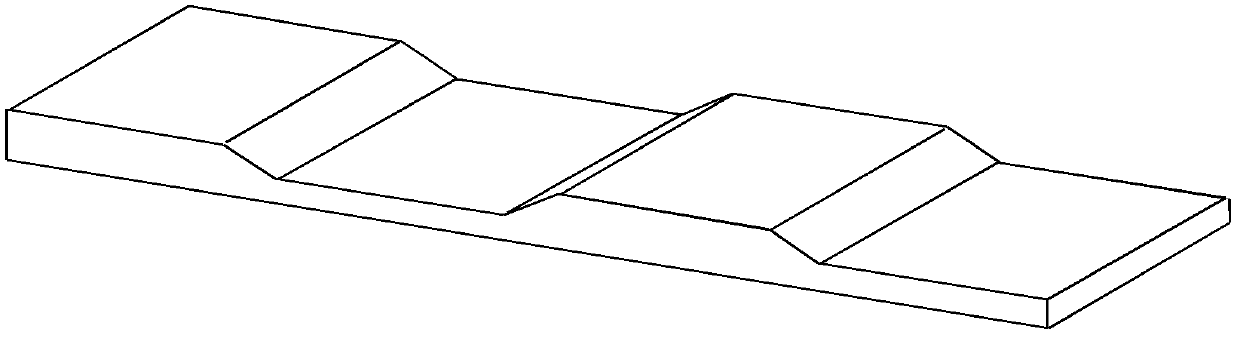

[0018] as attached figure 1 with 2 As shown, the difference between the commonly used plastic sheet and the continuous variable section plastic sheet is very obvious. Because the continuous variable section plastic sheet has various specifications and requirements, according to the current processing method, it is time-consuming and expensive. Extrusion equipment for cross-sectional plastic sheets.

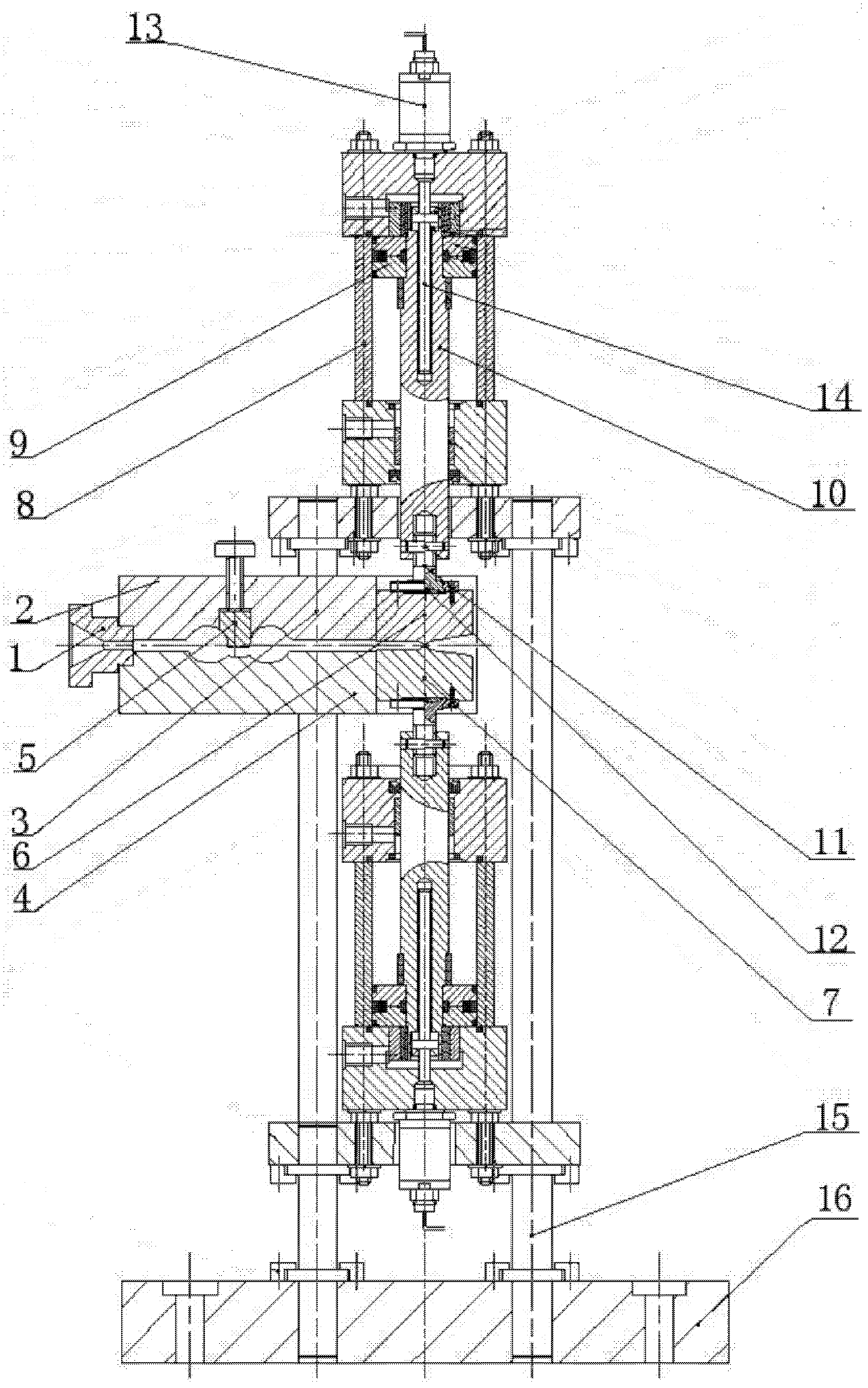

[0019] as attached image 3 As shown in , the continuous variable cross-section plastic sheet extrusion equipment consists of a servo hydraulic cylinder part and an extrusion die part.

[0020] The servo hydraulic cylinder part consists of a displacement sensor 13, a pull rod, a hex nut, a spring washer, a rear cylinder cover, an O-ring, a wear-resistant guide ring, a magnet, a Y-ring, a cylinder barrel, a front cylinder cover, a dust-proof ring, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com