Pipeline flash butt-welding welding seam plasma slag clearing and heat treatment machine

A technology of flash butt welding and plasma, which is applied in heat treatment furnaces, heat treatment equipment, plasma welding equipment, etc., can solve the problems of small pipes that cannot be inserted into the pipe, labor intensity of workers, complex structure, etc., and achieve good weld repair effect, The effect of good equipment flexibility and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

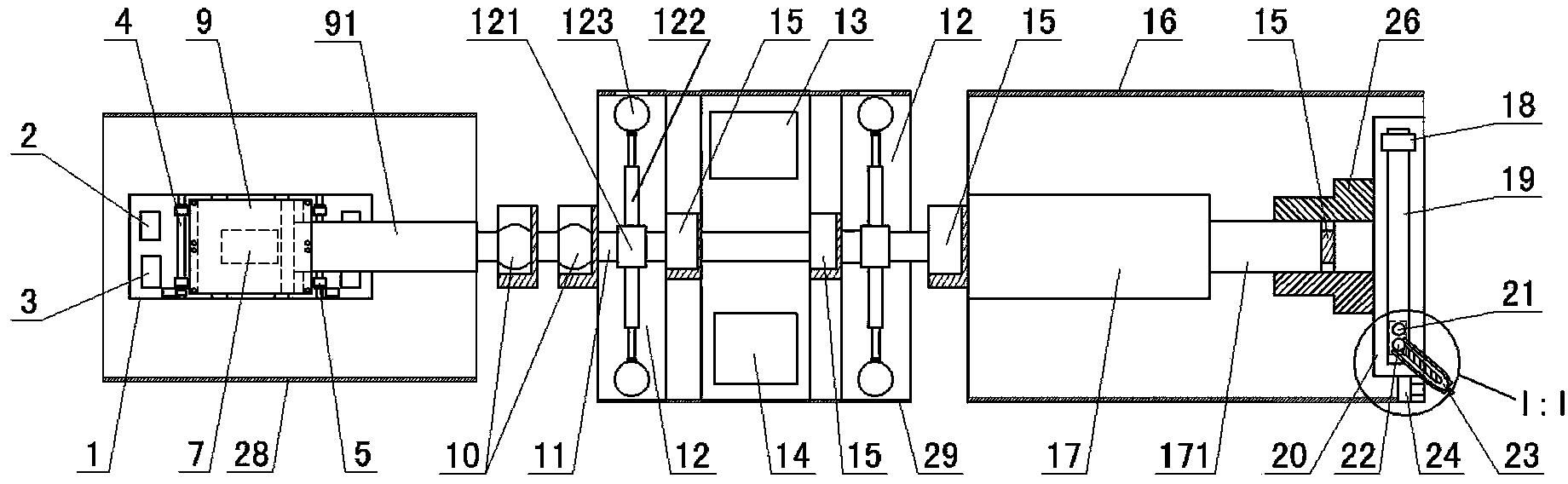

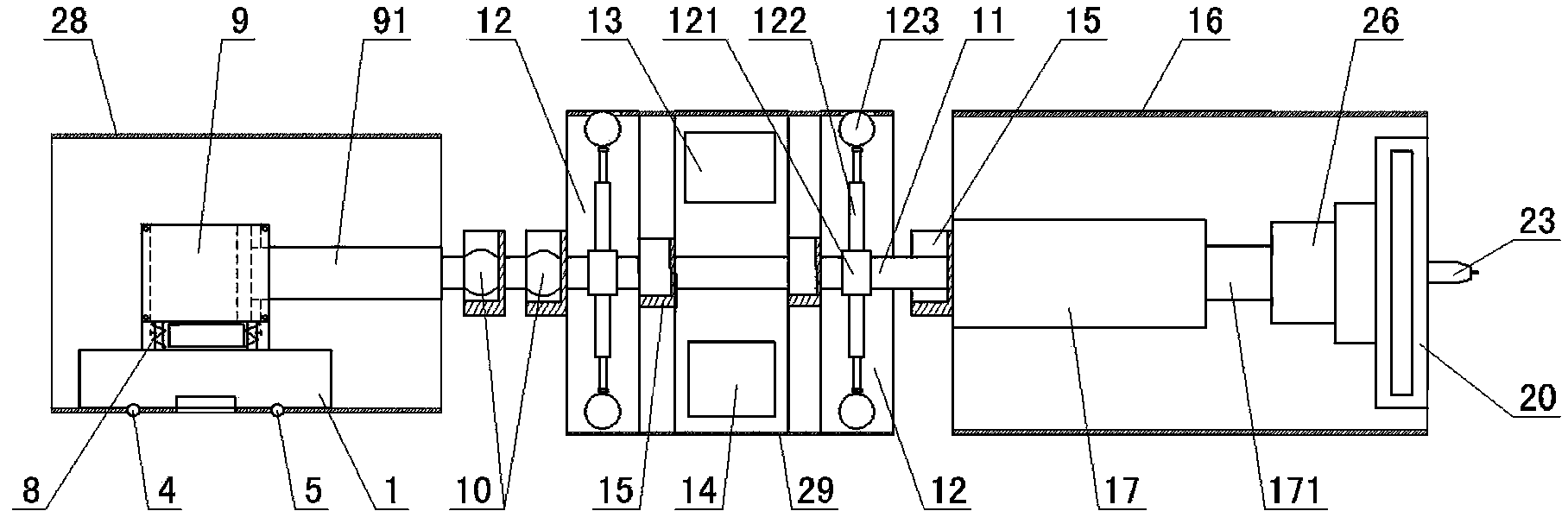

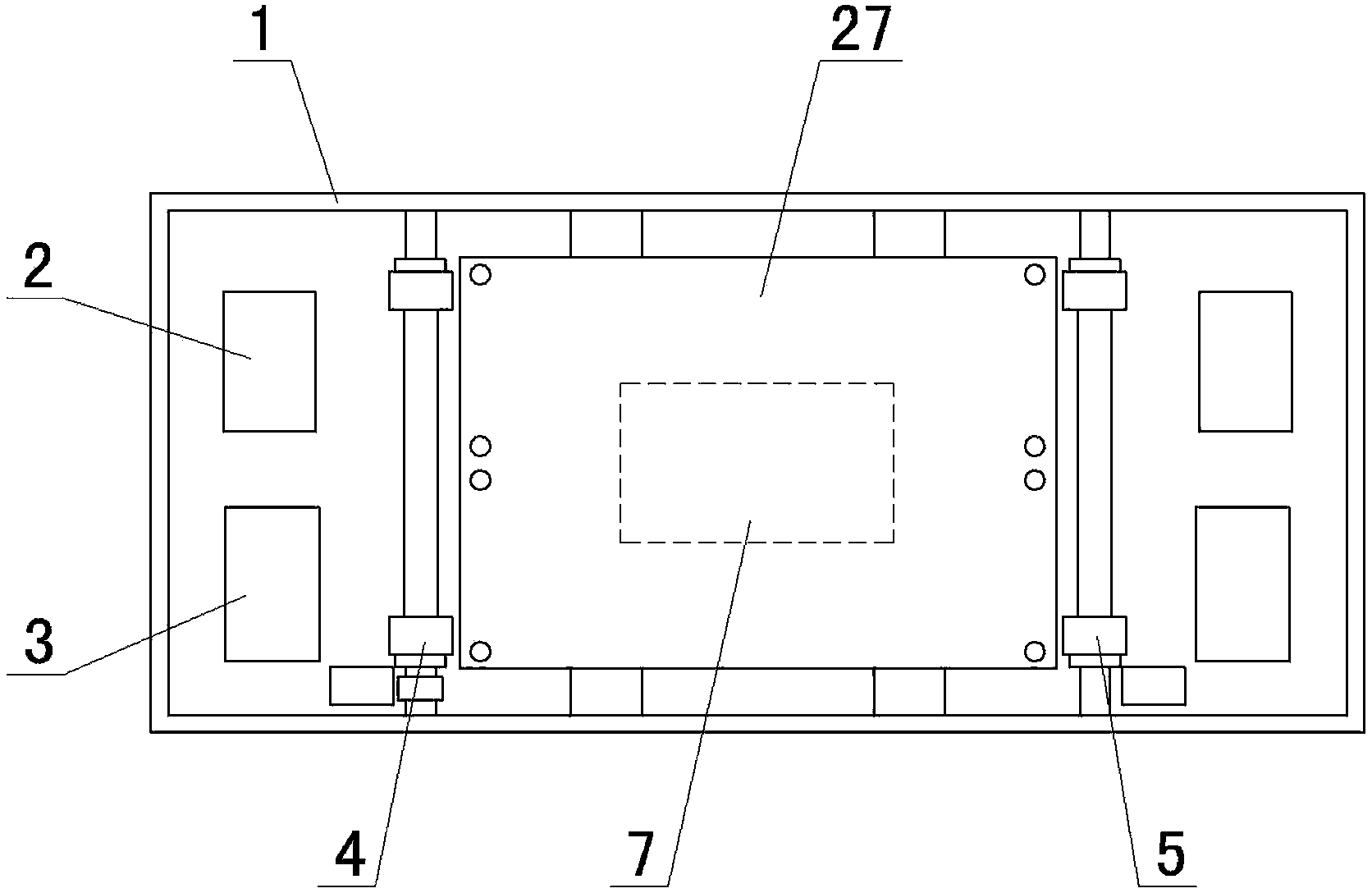

[0026] Such as Figure 1-Figure 7 As shown, the pipeline flash butt welding seam plasma slag removal and heat treatment machine of the present invention includes a pipe crawling positioning mechanism, an inner pipe welding seam plasma slag removal and heat treatment mechanism that promotes displacement and positioning through the pipe crawling positioning mechanism, and is used for The monitoring unit that controls the crawling positioning mechanism in the tube and the plasma cleaning and heat treatment mechanism of the welding seam in the tube, and the position adjustment mechanism in the tube that controls the action through the monitoring unit. The position adjustment mechanism in the tube is set in the crawling positioning mechanism in the tube and the welding seam plasma cleaning and slag removal. Between heat treatment institutions. Among them, such as figure 1 and image 3 As shown, the in-tube crawling positioning mechanism is a work cart that integrates mechanical, ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com