Printable environment-friendly electric aluminium release type material with high strippability

A release material, anodized aluminum technology, applied in the direction of coating, etc., can solve problems such as low surface tension, environmental pollution, and health damage to operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

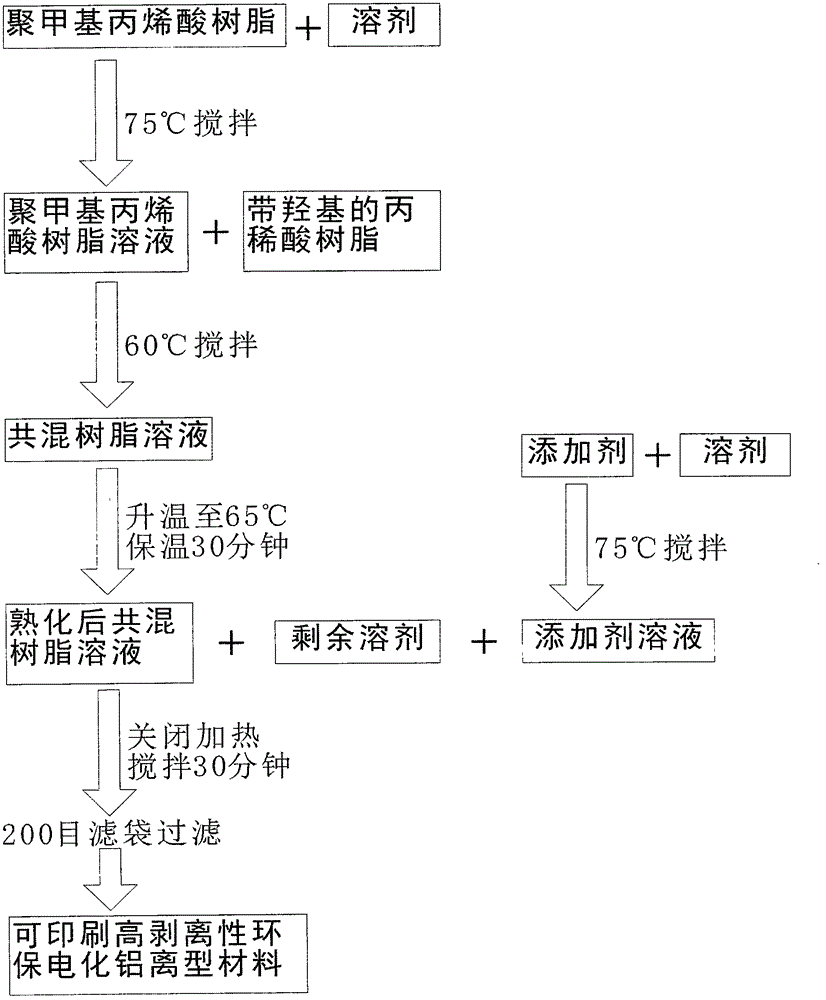

[0016] The embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings. Take the production of 100 kg of this printable high-peelability environmentally friendly anodized aluminum release material as an example.

[0017] The first step is to weigh 50 kilograms of solvent and put it into the material vat, turn on the heating, set the temperature to 75 degrees Celsius, start stirring when the temperature of the solvent in the vat rises to 75 degrees Celsius, and put 20 kilograms of polymethacrylic resin into it, and speed up Stirring speed, so that the material liquid is heated evenly.

[0018] In the second step, when the resin in the material tank is completely dissolved, the stirring speed is reduced, the heating temperature is set to 60 degrees Celsius, and 5-10 kilograms of acrylic resin with hydroxyl groups are dropped in. The acrylic resin with hydroxyl group is blended with polymethacrylic resin during the disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com