Optical glass

An optical glass and optical constant technology, applied in the field of optical glass, can solve the problems of excessive coloring, insufficient numerical limit, poor chemical durability, etc., and achieve the effect of reducing manufacturing cost, reducing loss and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

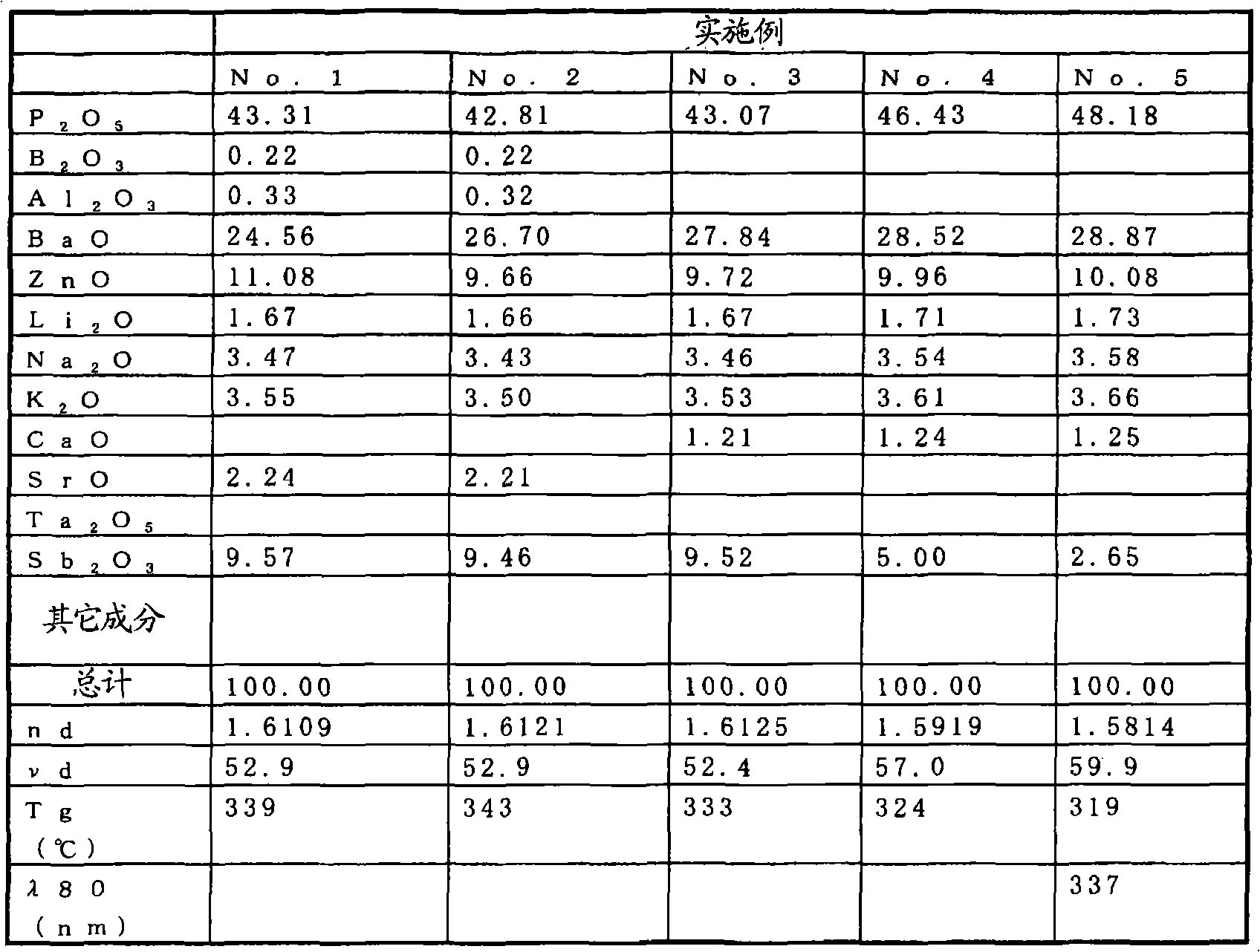

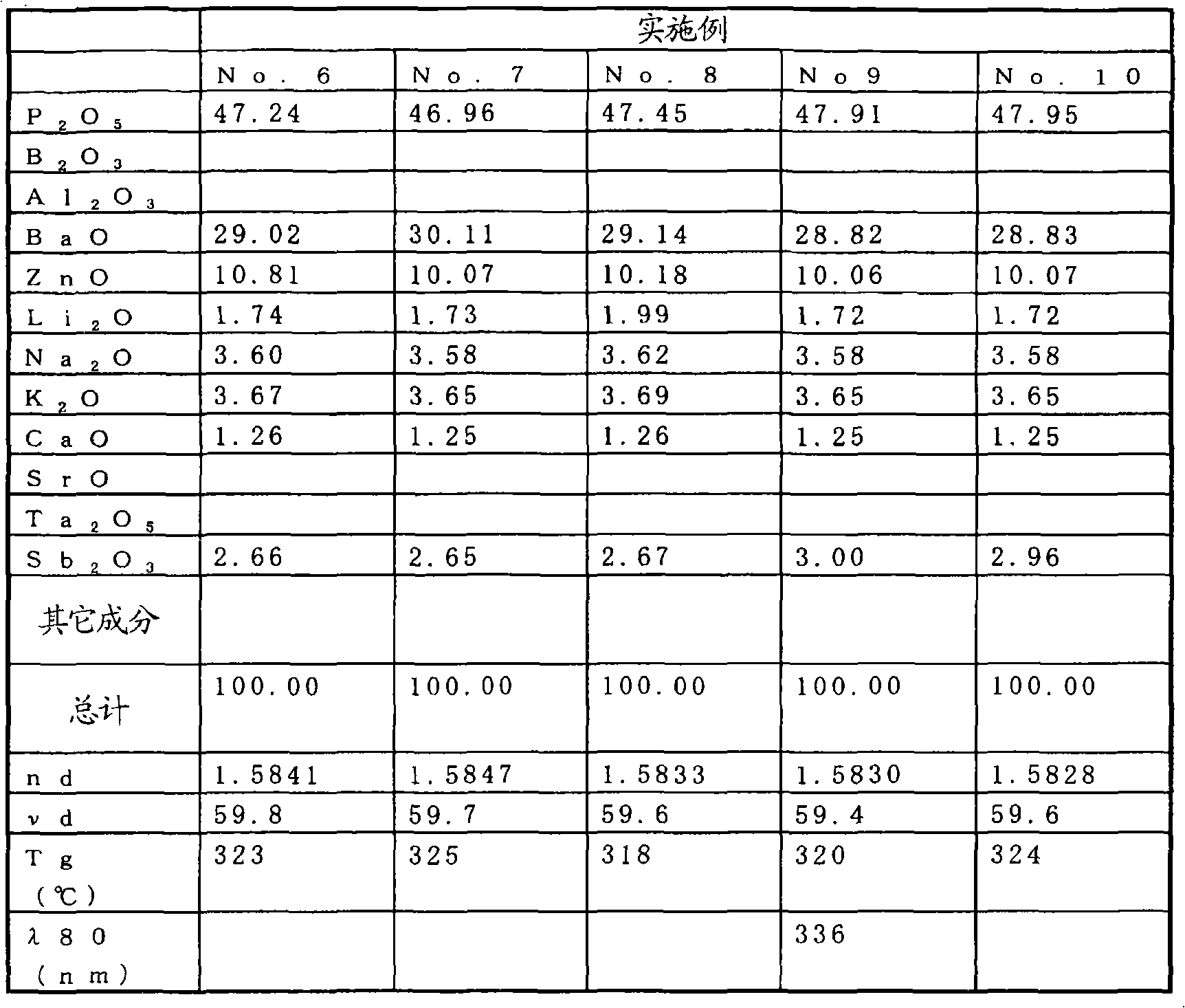

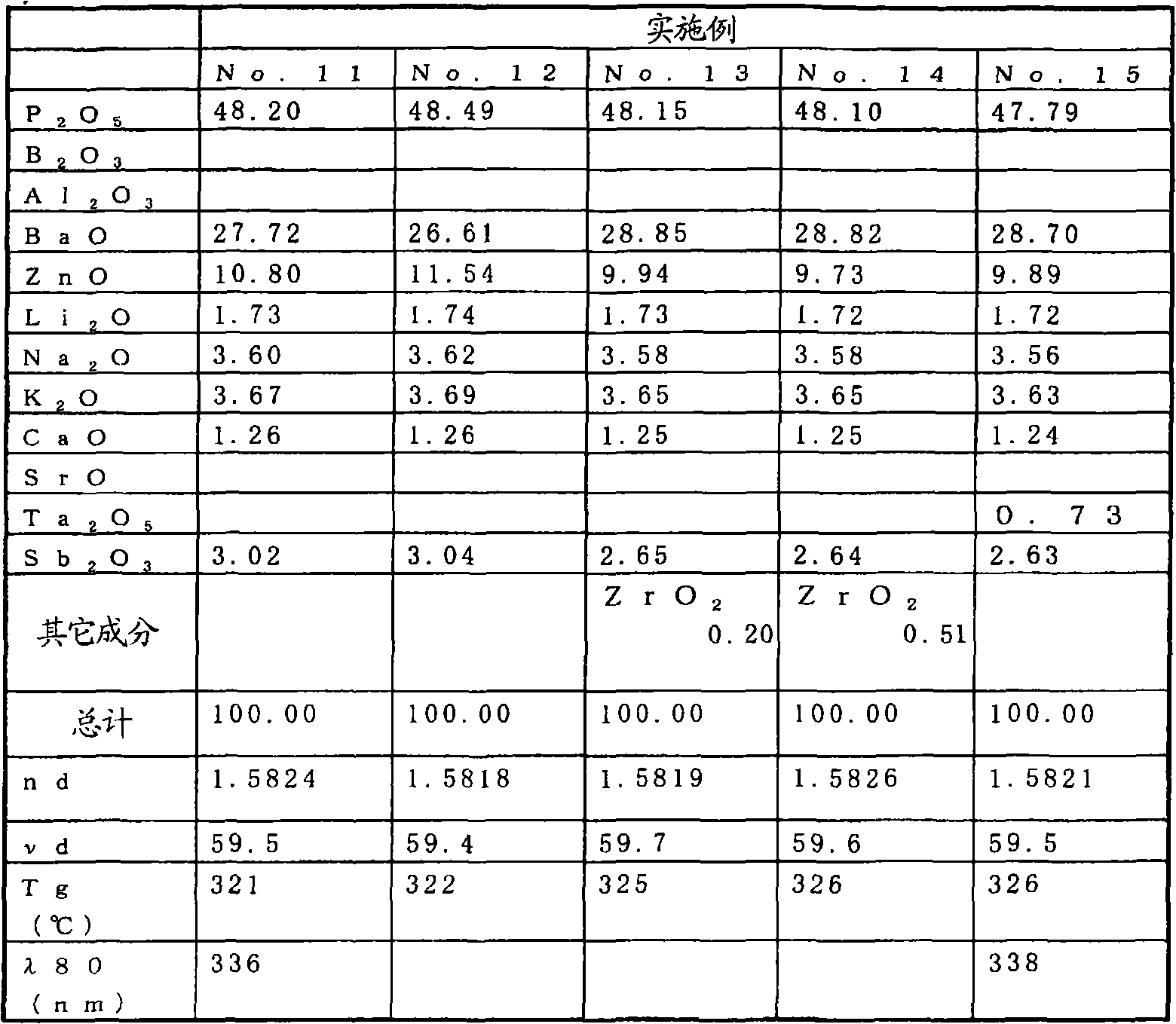

[0110] The composition of the examples (No.1 to No.20) of the optical glass of the present invention and the composition of the comparative examples (No.A to D) of the conventional optical glass were compared with the refractive index (nd) and Abbe The measurement results of the number (νd), glass transition temperature (Tg) (°C), and λ80 (nm) are shown in Tables 1 to 5 together. All the content of each component in a table|surface is shown by the mass % of an oxide basis.

[0111] The glass (No.1~No.20) shown in the embodiment of the present invention shown in Table 1~Table 5 all can be obtained as follows: according to the fixed composition shown in Table 1~Table 4, weigh phosphate, orthophosphoric acid , oxides, carbonates, nitrates, hydroxides and other general optical glass raw materials, the mixed raw materials are added to platinum crucibles, etc., depending on the melting properties caused by different compositions, at 1000 ° C ~ 1200 ° C It melts at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com