Wear-resistant steel with good forming performance for dumper carriage body and production method thereof

A technology of formability and production method, applied in wear-resistant steel for dump car body with good formability and its production field, can solve U-shaped bending deformation, unqualified formability, high-strength wear-resistant steel plate processing two Eliminates problems such as secondary warping and deformation, and achieves good forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Pure molten steel is obtained by smelting, and then a defect-free cast slab is produced by continuous casting at constant pulling speed, electromagnetic stirring, and dynamic light reduction. The weight percentage of its composition is: C: 0.16%, Si: 0.15%, Mn: 0.90%, P: 0.018%, S: 0.010%, Als: 0.020%, Nb: 0.020%, Ti: 0.012%, Cr: 0.30%, Mo: 0.10%, B: 0.0005%, O: 0.0025%, N: 0.0050%, H: 1.8ppm, the rest is Fe and unavoidable impurities; the reheating temperature range of the slab is 1120°C, and the soaking period is 30 minutes to eliminate the temperature gradient.

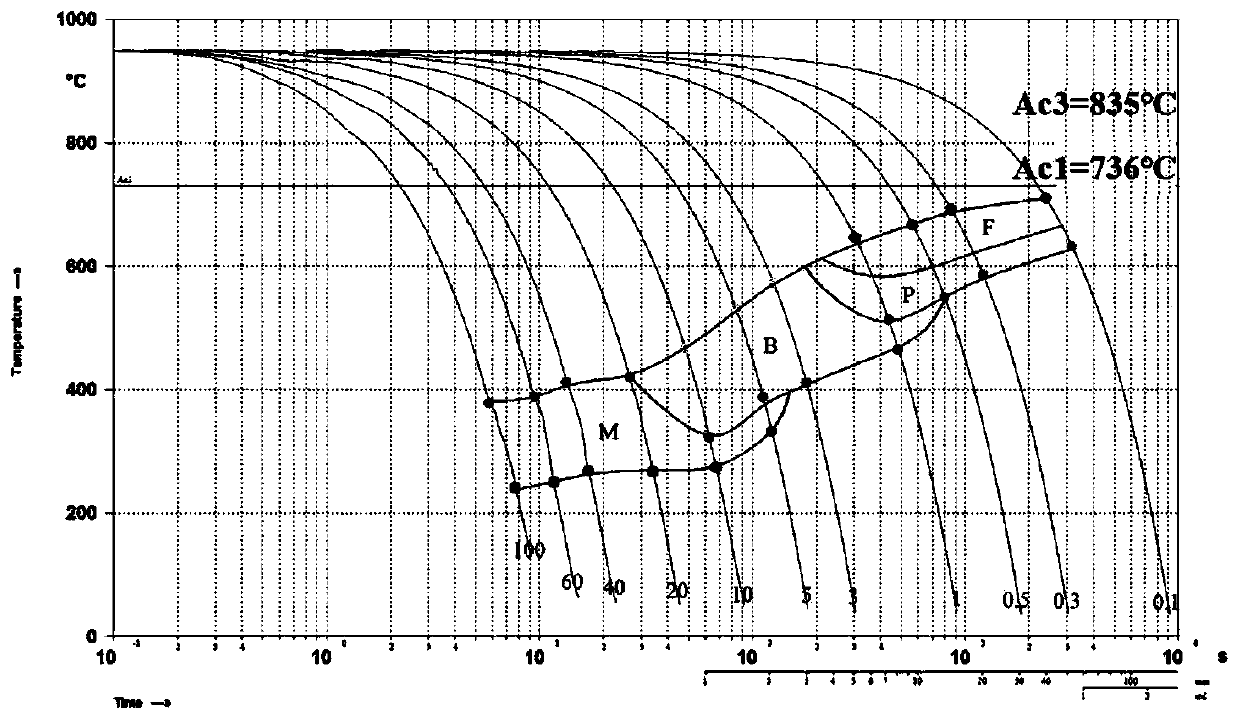

[0055] Double-pass controlled rolling process, that is, rough rolling in the austenite recrystallization zone + finishing rolling in the austenite non-recrystallization zone controlled rolling, rough rolling in the austenite recrystallization zone deformation austenite grain uniformity control process , in order to ensure uniform deformed austenite grains, the reduction rate of each pass is gradua...

Embodiment 2

[0066] Example 2: Purified molten steel is obtained by smelting, and then a defect-free cast slab is produced by technologies such as constant pulling speed continuous casting, electromagnetic stirring, and dynamic soft reduction, and its composition weight percentage is: C: 0.18%, Si: 0.20 %, Mn: 1.00%, P: 0.015%, S: 0.008%, Als: 0.030%, Nb: 0.025%, Ti: 0.015%, Cr: 0.40%, Mo: 0.15%, B: 0.0009%, O: 0.0020 %, N: 0.0045%, H: 1.5ppm, the rest is Fe and unavoidable impurities. The reheating temperature range of the slab is 1160°C, and the soaking period is 40 minutes to eliminate the temperature gradient;

[0067] Double-pass controlled rolling process, that is, rough rolling in the austenite recrystallization zone + finishing rolling in the austenite non-recrystallization zone controlled rolling, rough rolling in the austenite recrystallization zone deformation austenite grain uniformity control process , in order to ensure uniform deformed austenite grains, the reduction rate o...

Embodiment 3

[0078] Example 3: Pure molten steel is obtained by smelting, and then a defect-free cast slab is produced by technologies such as constant pulling speed continuous casting, electromagnetic stirring, and dynamic light reduction. The composition weight percentage is: C: 0.20%, Si: 0.23 %, Mn: 1.2%, P: 0.013%, S: 0.007%, Als: 0.045%, Nb: 0.035%, Ti: 0.021%, Cr: 0.45%, Mo: 0.18%, B: 0.0011%, O: 0.0022 %, N: 0.0040%, H: 1.4ppm, the rest is Fe and unavoidable impurities. The reheating temperature range of the slab is 1150°C, and the soaking period is 45 minutes to eliminate the temperature gradient.

[0079] Double-pass controlled rolling process, that is, rough rolling in the austenite recrystallization zone + finishing rolling in the austenite non-recrystallization zone controlled rolling, rough rolling in the austenite recrystallization zone deformation austenite grain uniformity control process , in order to ensure uniform deformed austenite grains, the reduction rate of each p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com