Transferring films, multilayered sheets and manufacturing methods thereof

A transfer film and laminate technology, applied in the field of transfer film, can solve the problems of increasing hardness, deterioration of molding performance, and reducing the scratch resistance of the finished film surface, so as to prevent appearance damage, excellent elongation rate, excellent resistance Effect of scratch and moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

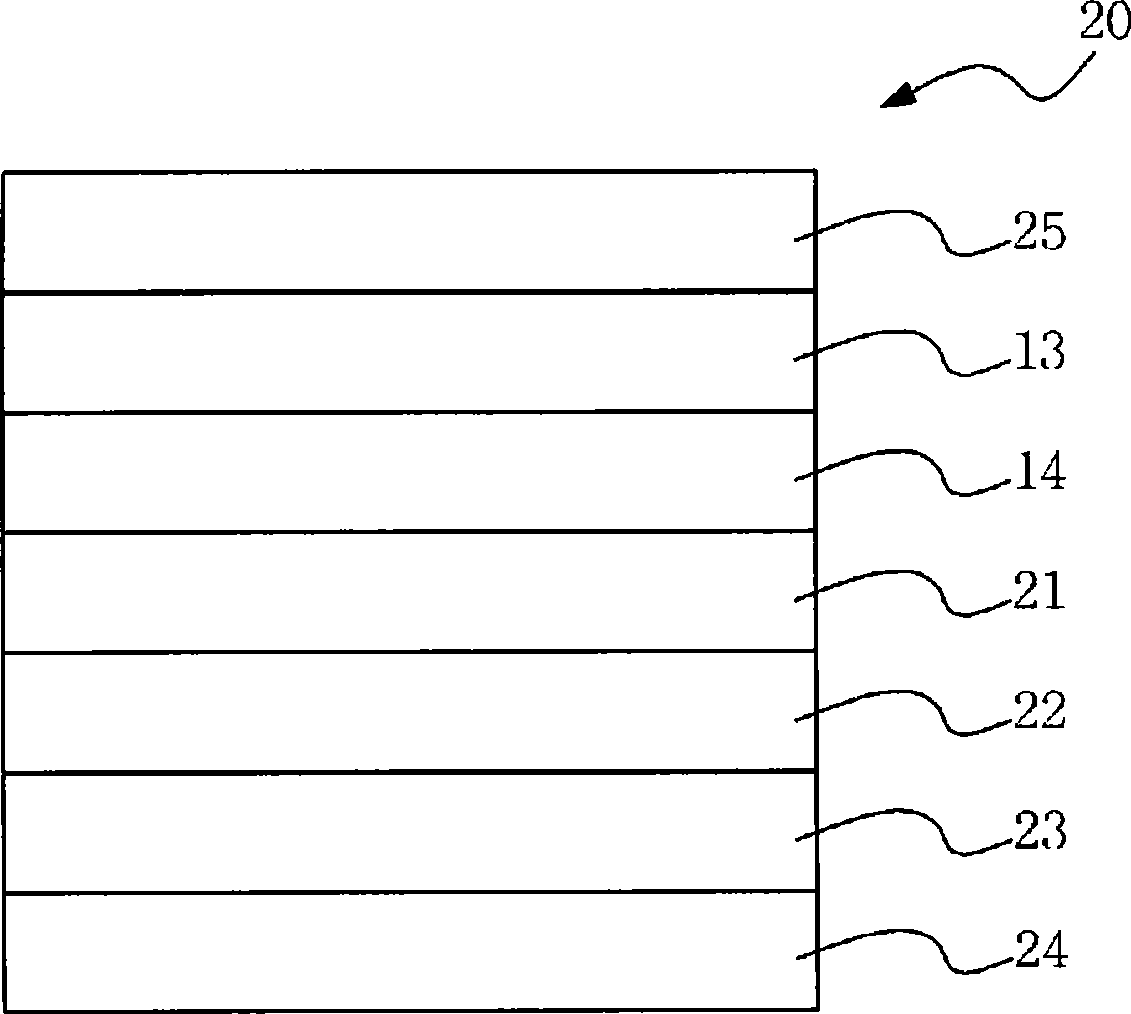

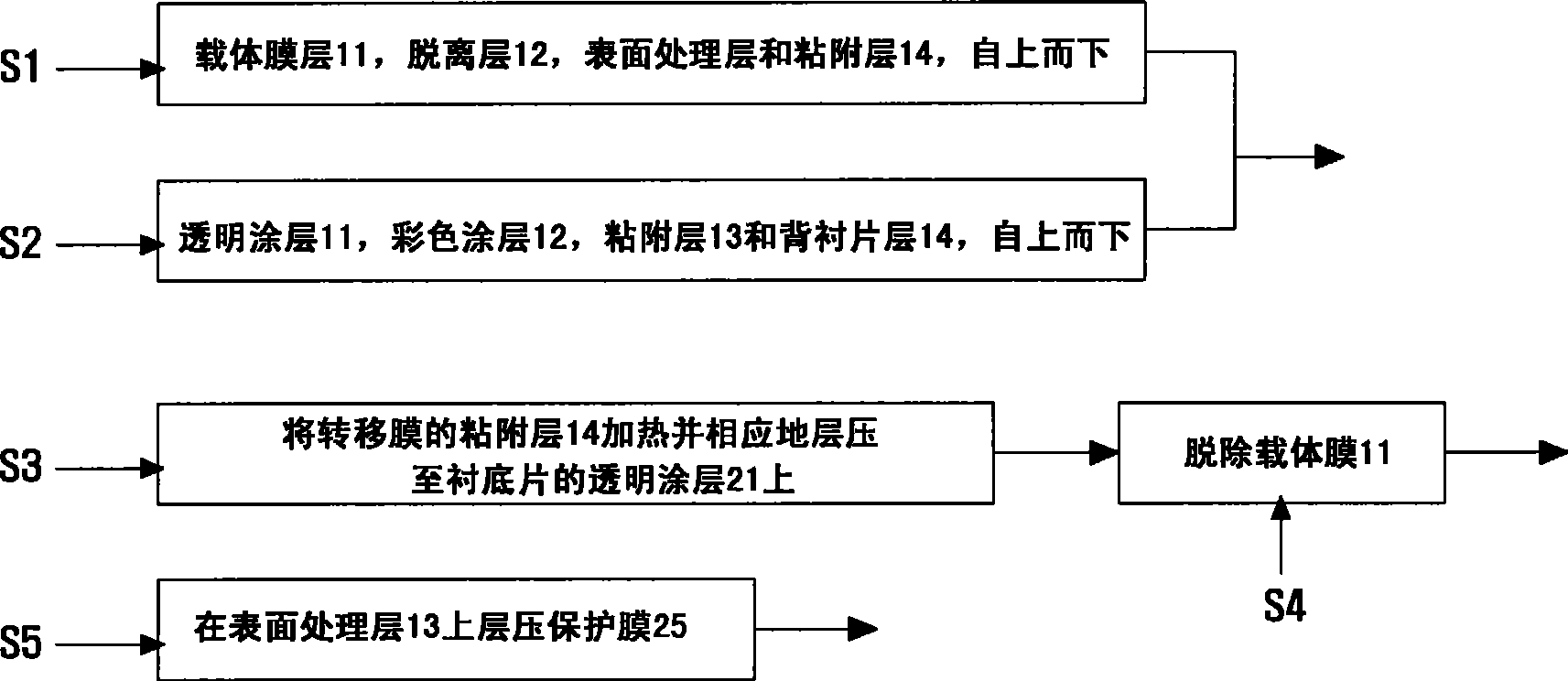

[0047] The production method of the present invention may further include a step of laminating a protective film on the transferred surface treatment layer. If a carrier layer is formed on the transfer film, the protective film is laminated after removing the layer. Since a release layer is formed under the carrier layer, the carrier layer can be easily removed. Examples of the method of forming the protective layer after removing the carrier layer include a method of laminating a protective film such as a polyethylene film or a polypropylene film in which a pressure-sensitive adhesive is applied to one side with a lamination roll.

[0048] The invention also relates to injection molded articles comprising a laminate according to the invention.

[0049] As described above, the transfer film of the present invention and a laminate composed of the transfer film are excellent in weather resistance, moldability and scratch resistance. Therefore, the laminated sheet of the presen...

Embodiment 1

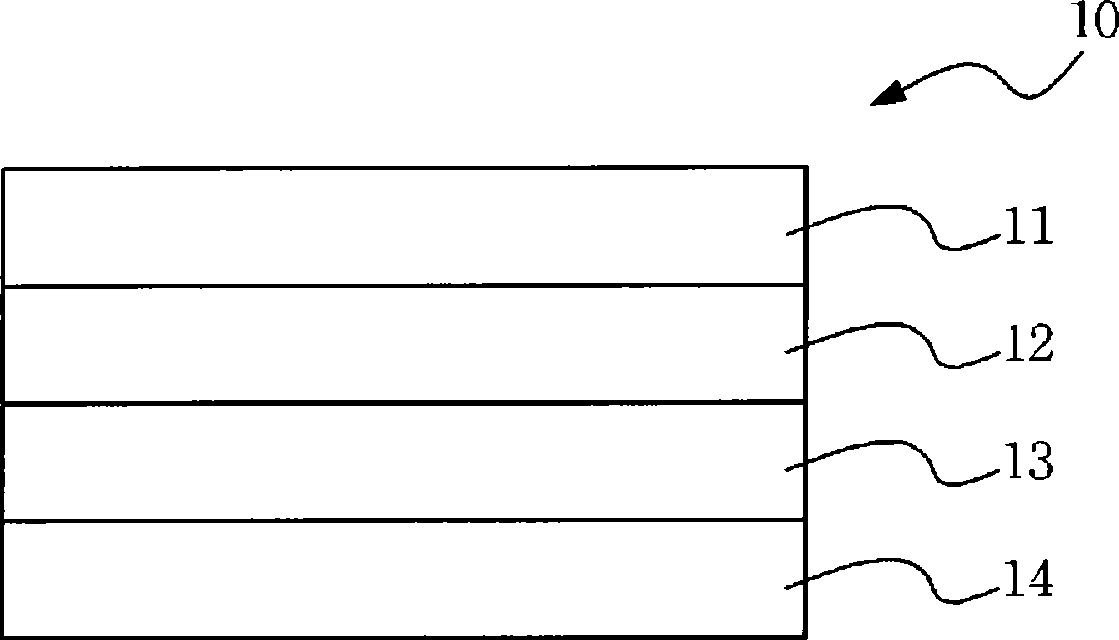

[0053] Embodiment 1: the preparation of transfer film (1)

[0054] A silicone resin release agent was applied to a thickness of 0.1 μm on a 50 μm thick polyethylene terephthalate film as a base layer to form a release layer. Then, using a wire bar coater, coating a composition with a thickness of 10 μm for forming a surface treatment layer with a viscosity of 50 cps on the release layer, the composition includes 20 parts by weight of modified acrylic resin, 10 parts by weight of vinyl acetate resin, 0.5 parts by weight of wax, 0.3 parts by weight of silicone resin, 25 parts by weight of toluene, 17 parts by weight of methyl ethyl ketone and 13 parts by weight of ethyl acetate, and then it was heated at 120 ° C Dry at a certain temperature to form a surface treatment layer. On the surface treatment layer thus formed, an acrylamide copolymer resin adhesive was applied to a thickness of 2 μm using a wire bar coater, and dried at 120° C. to prepare a transfer film.

Embodiment 2

[0055] Embodiment 2: the preparation of transfer film (2)

[0056] Except that the viscosity is 50cps, it contains 20 parts by weight of modified acrylic resin, 10 parts by weight of vinyl acetate resin, 5 parts by weight of methyl diisocyanate, 0.5 parts by weight of wax, 0.3 parts by weight of silicone resin, A transfer film was prepared in the same manner as in Example 1 above, except that a composition of 25 parts by weight of toluene, 17 parts by weight of methyl ethyl ketone, and 13 parts by weight of ethyl acetate was used as the composition for forming the surface treatment layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com