Hard metal complex plasticizer and method of manufacturing the same and method of use thereof

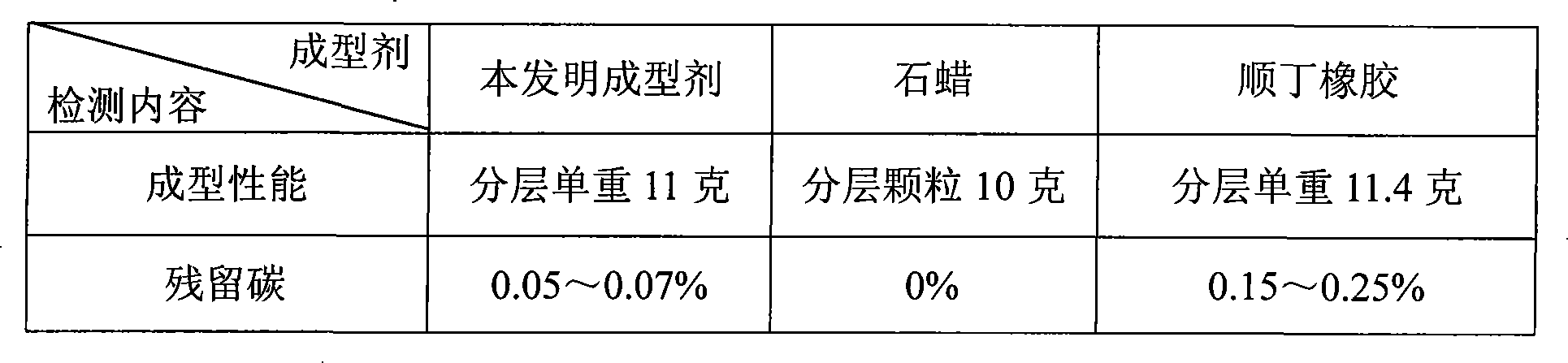

A cemented carbide and molding agent technology, applied in the direction of adhesives, etc., can solve the problems of low green strength, high residual carbon, easy aging, etc., and achieve the effect of good molding performance and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A cemented carbide forming agent, its components and mass percentages are: 20% paraffin, 36% SBS solution with a concentration of 15%, and 44% No. 120 solvent gasoline.

[0023] The production method of the above-mentioned molding agent is: heat and melt the paraffin wax in a steam jacketed container, pass through a 320-mesh screen to remove impurities, pour it into solvent gasoline, stir evenly, then pour the SBS solution into it, and fully stir it to obtain The required forming agent solution is kept warm for later use.

[0024] The method of using the above-mentioned molding agent is: add the above-mentioned molding agent to the cemented carbide powder at a ratio of 90mL / kg within 5 minutes after the preparation is completed, stir and mix evenly, and dry, wipe and sieve, and granulate to prepare Adhesive mixture is ready for use.

Embodiment 2

[0026] A cemented carbide forming agent, its components and mass percentages are: 27% of paraffin wax, 40% of SBS solution with a concentration of 20%, and 33% of No. 120 solvent gasoline.

[0027] The production method of above-mentioned molding agent is the same as embodiment 1.

[0028] The method of using the above-mentioned molding agent is: within 10 minutes after the preparation is completed, the above-mentioned molding agent is added to the ball mill together with the cemented carbide powder at a ratio of 110mL / kg for ball milling and crushing, so that the powder and the molding agent are mixed evenly, and the obtained The mixed slurry is spray-dried and granulated to prepare the rubber-mixed mixture for later use.

Embodiment 3

[0030] A cemented carbide forming agent, its components and their mass percentages are: 20% paraffin, 36% SBS solution with a concentration of 10%, and 44% No. 120 solvent gasoline.

[0031] The production method of above-mentioned molding agent is the same as embodiment 1.

[0032] The usage method of above-mentioned molding agent is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com