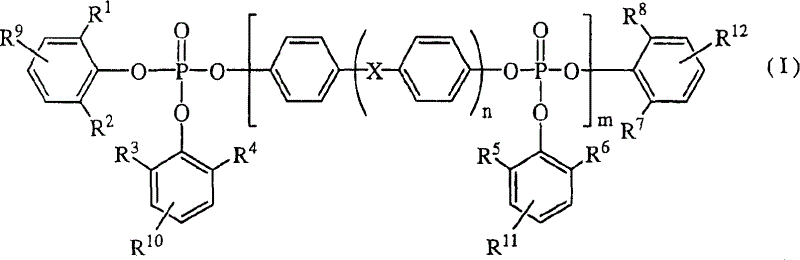

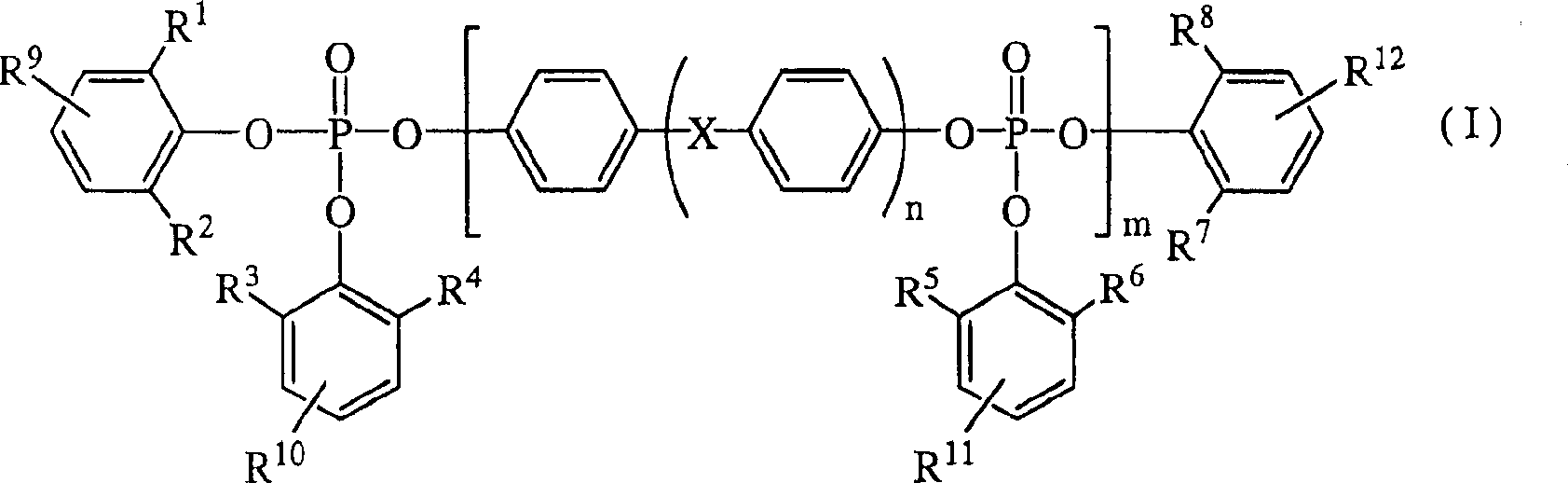

Polyarylene thioether resin composition

A technology of polyarylene sulfide and resin composition, applied in coating and other directions, can solve the problems of reduced physical and mechanical properties, reduced mechanical properties, phosphate exudation, etc., and achieves improved molding operation performance, accelerated crystallization speed, The effect of oozing improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~11

[0070] Components (A), (B) and (C) shown in Tables 1 to 2 were put into a Henschel mixer in the amounts shown in Tables 1 to 2, and premixed for 5 minutes. Further according to the situation, add (D), (E) components according to the amount shown in Tables 1 to 2, mix with a blender for 2 minutes, and put the mixed material into an extruder with a barrel temperature of 320°C (Co., Ltd. ) Ikegai Manufacturing PCM30), the polyphenylene sulfide resin composition was pelletized. Next, the pellets were made into various test pieces for evaluation. The evaluation items and evaluation methods are as follows.

[0071] [Crystallinity]

[0072] Using an injection molding machine (IS50EP manufactured by Toshiba Machine Co., Ltd.), under the cylinder temperature: 320 ° C; mold temperature: 100 ° C: and the following molding conditions, a flat test piece with a thickness of 3 mm and a size of 50 mm × 70 mm was molded. After standing at room temperature for a certain period of time, the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com