Optical glass, optical prefabricated member and optical element

A technology for optical glass and optical components, applied in optical components, optics, instruments, etc., can solve the problems of low production yield, white turbidity and fogging on the glass surface, and achieve the effect of improving molding performance and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

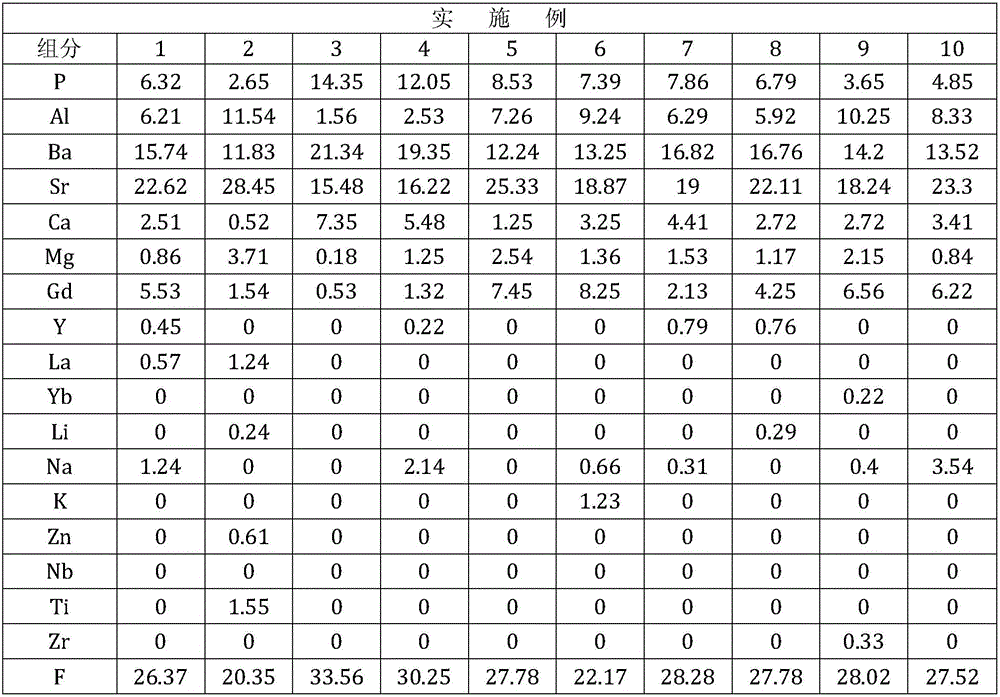

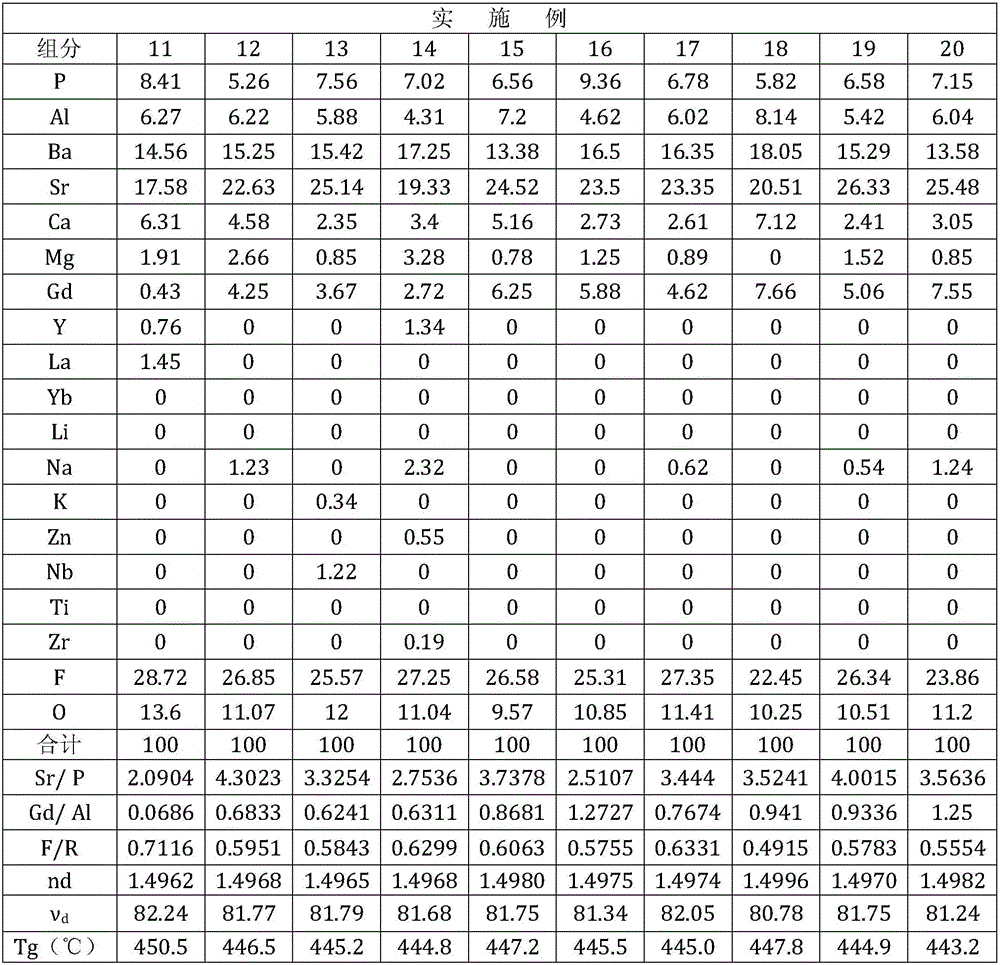

Examples

Embodiment Construction

[0020] The present invention is not limited to the following aspects, and can be implemented with appropriate changes within the scope of the purpose of the present invention. It should be noted that, for overlapping descriptions, sometimes omitted descriptions are used.

[0021] Ⅰ. Optical glass

[0022] Each component constituting the optical glass of the present invention will be described below. In the description of the present invention, each component and its content, unless otherwise specified, each component represents the sum of the elements including all possible ion valence states, and its content is represented by the weight percentage of the component in all components express. In addition, in the following description, when referring to a predetermined value or less or a predetermined value or more, the predetermined value is also included.

[0023] P is an important cationic component as a glass network former, and when its content is less than 10%, the stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com