Reinforcing porcelain blank suitable for Longquan green glaze and preparation method of product thereof

A technology for strengthening porcelain and blanks, which is applied in the field of ceramics, can solve the problems of energy consumption and high production costs, and achieve the effects of low production costs, high pass rate and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

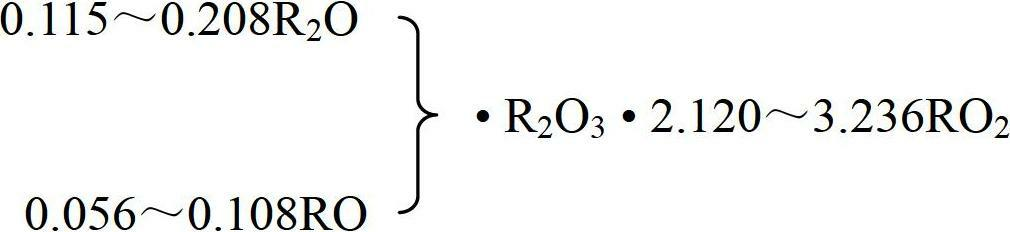

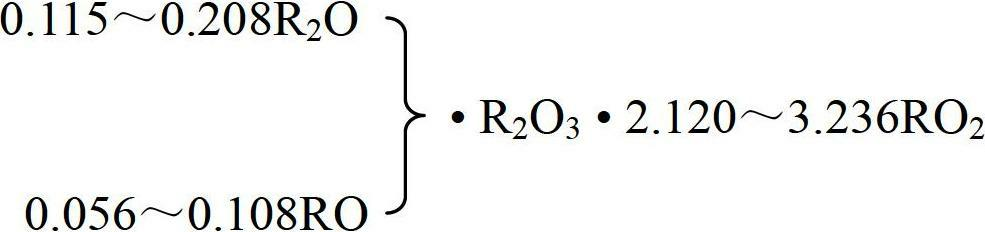

Method used

Image

Examples

Embodiment 1

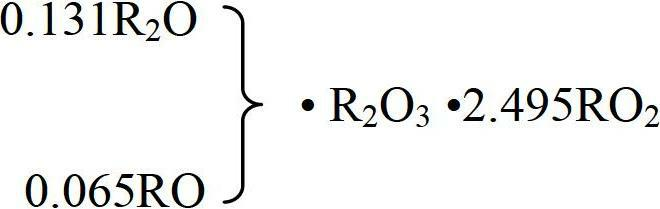

[0020] In this embodiment, a strengthened porcelain blank suitable for Longquan celadon decoration is composed of a base material and a toughening reinforcing material. According to the mass percentage, the base material is composed of 25% feldspar, 59% Longyan kaolin, and 12% Longquan clay. , quartz 2%, calcined talc 1%, lithium china stone 1%; toughening and reinforcing materials are 12% of the base material, and its composition is: alumina micropowder 90%, zirconia micropowder 10%, alumina micropowder and zirconia micropowder The fineness is 40~65μm. The general chemical formula of the strengthened porcelain blank in this embodiment is:

[0021] 0.131 R 2 O 0.065 RO · R 2 O 3 ...

Embodiment 2

[0024] In this embodiment, a strengthened porcelain blank suitable for Longquan celadon decoration is composed of a base material and a toughening reinforcing material. According to the mass percentage, the base material is composed of 28% feldspar, 52% Longyan kaolin, and 15% Longquan clay. , quartz 2%, calcined talc 1%, lithium china stone 2%; the toughening and reinforcing material is alumina micropowder, the dosage is 16% of the base material, and the fineness is 40-65μm. The general chemical formula of the strengthened porcelain blank in this embodiment is:

[0025] 0.154 R 2 O 0.079 RO · R 2 O 3 · 2.753 RO 2

...

Embodiment 3

[0028] In this embodiment, a strengthened porcelain blank suitable for Longquan celadon decoration is composed of a base material and a toughening reinforcing material. According to the mass percentage, the base material is composed of 30% feldspar, 55% Longyan kaolin, and 12% Longquan clay , quartz 2%, calcined talc 1%; the toughening and reinforcing material is 13% of the base material. 65 μm. The general chemical formula of the strengthened porcelain blank in this embodiment is:

[0029] 0.172 R 2 O 0.069 RO · R 2 O 3 · 2.852 RO 2

[0030] The preparation method of the strengthened porcelain product suitable for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com