Insulating silicone rubber, semiconductive silicone rubber, a cable head casing pipe and a preparing method

A technology of raw silicone rubber and insulating silicon, applied in the field of silicone rubber, can solve the problems of poor cable contact and easy combustion, and achieve the effects of good molding performance, good flame retardancy, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An embodiment of the present invention provides an insulating silicone rubber. The raw materials of the insulating silicone rubber include:

[0050] 100 parts of raw silicone rubber, 20 parts of modified white carbon black, 8 parts of structure control agent, 40 parts of glass powder, 30 parts of vitrified powder, 40 parts of flame retardant, and 1.5 parts of vulcanizing agent.

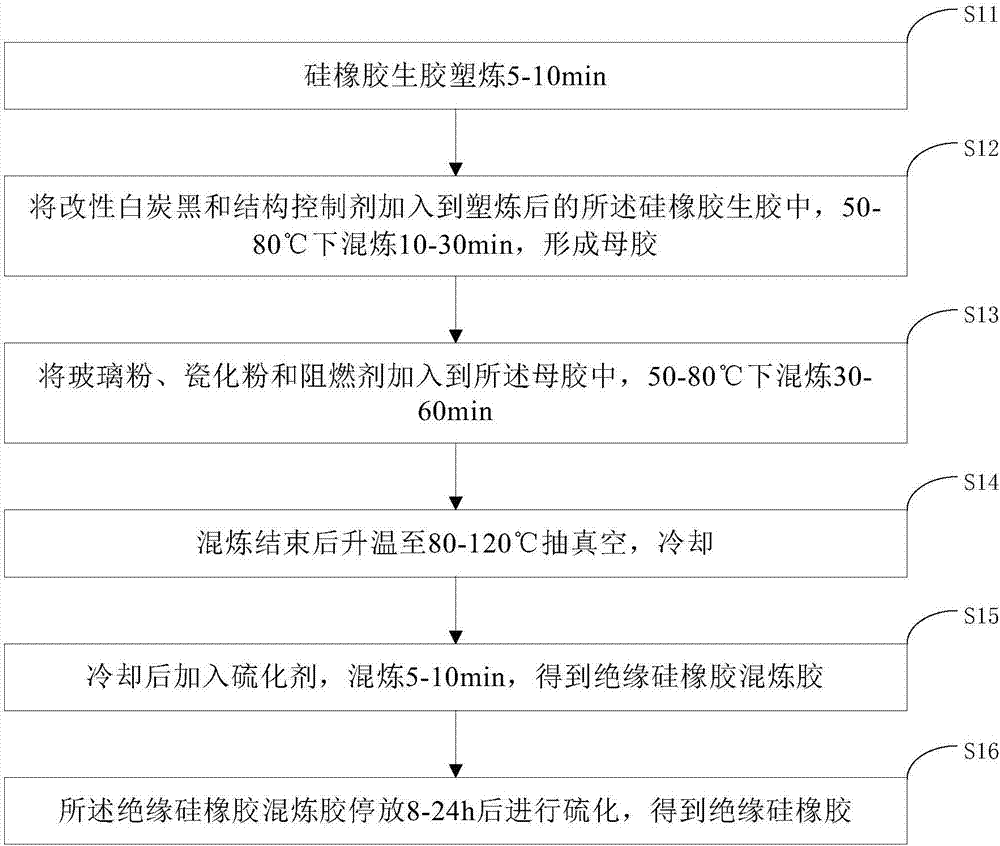

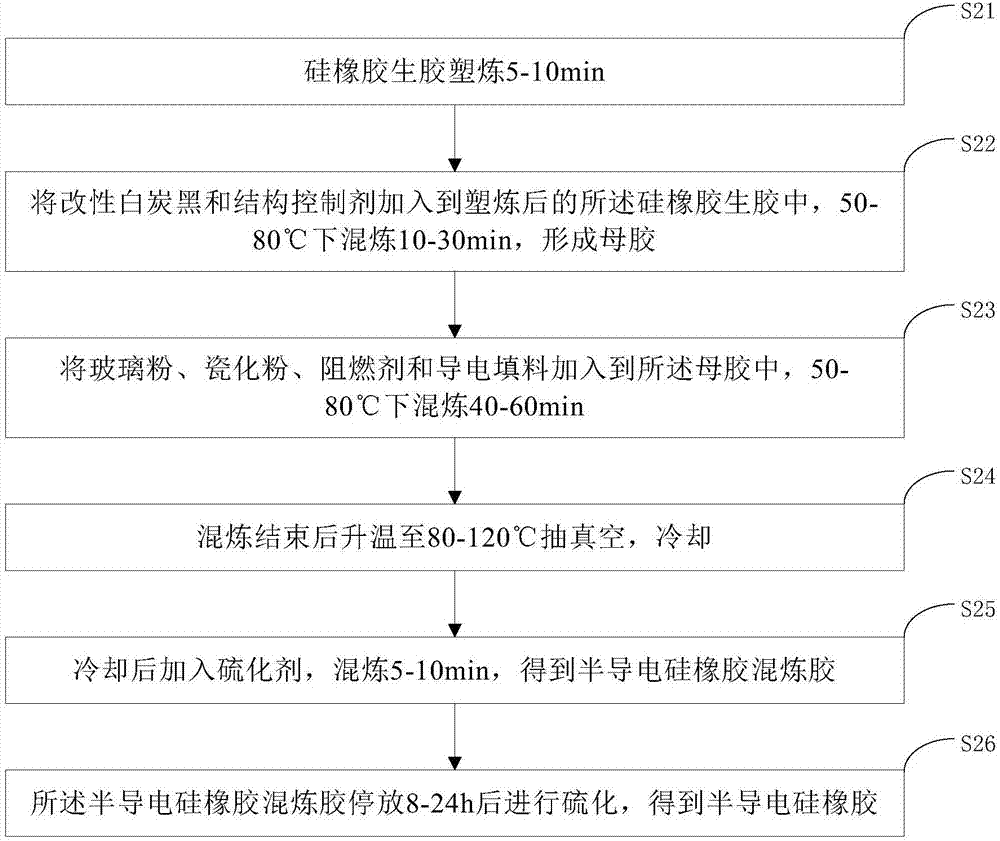

[0051] An embodiment of the present invention provides a method for preparing insulating silicone rubber, which specifically includes:

[0052] S111: Put the methyl silicone rubber raw rubber into a kneader and masticate for 5 minutes.

[0053] S112: After the mastication of methyl silicone rubber raw rubber is completed, add fumed silica and hydroxyl silicone oil modified by silane coupling agent to the masticated methyl silicone rubber raw rubber, and the temperature in the kneader is 60 Mix for 15 minutes under the condition of ℃ to form masterbatch;

[0054] S113: Add borosilicate glass p...

Embodiment 2

[0071] An embodiment of the present invention provides an insulating silicone rubber. The raw materials of the insulating silicone rubber include:

[0072] 100 parts of raw silicone rubber, 18 parts of modified white carbon black, 7 parts of structure control agent, 20 parts of glass powder, 5 parts of vitrified powder, 10 parts of flame retardant, and 1.5 parts of vulcanizing agent.

[0073] The embodiment of the present invention provides a method for preparing insulating silicone rubber, and the preparation steps of the method are the same as those in Embodiment 1. Among them, the modified silica is precipitated silica modified by silane coupling agent, the structure control agent is hydroxyl silicone oil and hexamethyldisilazane, the glass powder is bismuth oxide glass powder, and the vitrified powder is silica fume stone, the flame retardant is magnesium hydroxide and chloroplatinic acid, and the vulcanizing agent is double 25 vulcanizing agent. After testing, the Shore ...

Embodiment 3

[0079] An embodiment of the present invention provides an insulating silicone rubber. The raw materials of the insulating silicone rubber include:

[0080] 100 parts of raw silicone rubber, 30 parts of modified white carbon black, 10 parts of structure control agent, 50 parts of glass powder, 25 parts of porcelain powder, 40 parts of flame retardant, and 2 parts of vulcanizing agent.

[0081] An embodiment of the present invention provides a method for preparing insulating silicone rubber, which specifically includes:

[0082] S311: Put the methyl vinyl silicone rubber raw rubber into a kneader for mastication for 10 minutes.

[0083] S312: After the mastication of raw methyl vinyl silicone rubber, add precipitated silica and hexamethyldisilazane modified by titanate coupling agent to the masticated methyl vinyl silicone rubber In the raw rubber, knead for 10 minutes at a temperature of 80°C in a kneader to form a masterbatch;

[0084] S313: Add borate oxide glass powder, mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com