Aid for improving yield of liquid oil in oil delayed coking device and preparation method for aid

A technology of delayed coking and additives, which is applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc. It can solve problems such as coking, prolonging the start-up period, and increasing the yield of liquid oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 prepares the raw material of auxiliary agent of the present invention

[0029] Four groups of formula

[0030] .

[0031] The solvent is selected from s-100#, s-200# aromatic solvent oil or 120#, 200# alkane solvent oil, wherein, in the 3# auxiliary agent, the solvent used is 200# alkane solvent oil.

[0032] Preparation:

[0033] Add each component into the reaction vessel with a heating device according to the above four groups of different mass parts, control the temperature at 50-60°C, stir for 3 hours, and stir evenly to obtain the product of the present invention.

Embodiment 2

[0034] Embodiment 2 The evaluation test of the high liquid oil yield effect of the auxiliary agent described in the present invention

[0035] The raw oil used in the test was residual oil, which was taken from the delayed coking unit of Cangzhou Branch of Sinopec. Evaluation tests were carried out on the four groups of 1#-4# different products in the above Example 1 to investigate the effect of increasing the yield of liquid oil.

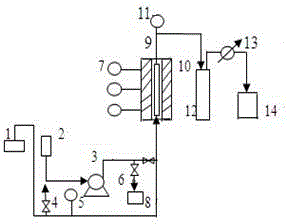

[0036] 2.1 Experimental device

[0037] Experimental device by figure 1 build.

[0038] 2.2 Test process conditions

[0039] Both blank test and dosing test adopt the following operating conditions:

[0040] 1) Residual oil entering furnace temperature is 100℃±1℃,

[0041] 2) The heating furnace temperature is 590℃±2℃,

[0042] 3) The temperature of residual oil out of the furnace is 496°C±2°C,

[0043] 4) Water vapor injection rate is 2% (accounting for residual oil flow),

[0044] 5) The flow rate of the residual oil in the furnace tube i...

Embodiment 3

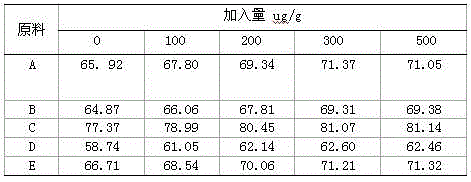

[0050] Example 3 3# additive application effect evaluation example

[0051] Additive 3# was used to investigate the effect of different additions on light oil yield and its adaptability to different coking raw materials. The addition amount is determined between 100-500 ug / g, and about 1500g of raw material residue is used for each blank test and additive test. The general properties of five different raw material residues are shown in the table below.

[0052] Test the properties of raw oil

[0053] ,

[0054] On the laboratory simulation device, according to the test process conditions, a blank test was carried out, and the addition test of the additives was 100ug / g, 200ug / g, 300ug / g and 500ug / g. The test data of total liquid yield before and after dosing is shown in the table below.

[0055] The effect of the amount of additives added on the total liquid yield

[0056]

[0057] It can be seen from the above table that the additives have the effect of increasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com