A kind of water-soluble dispersed scale inhibitor and its application

A water-soluble, antiscalant technology, applied in the purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of shortening the operation cycle of the device, more polymers in the four-effect evaporation unit, and lower product yield, achieving significant economic Benefits and social benefits, prolonging the production cycle, and inhibiting the effect of free radical polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

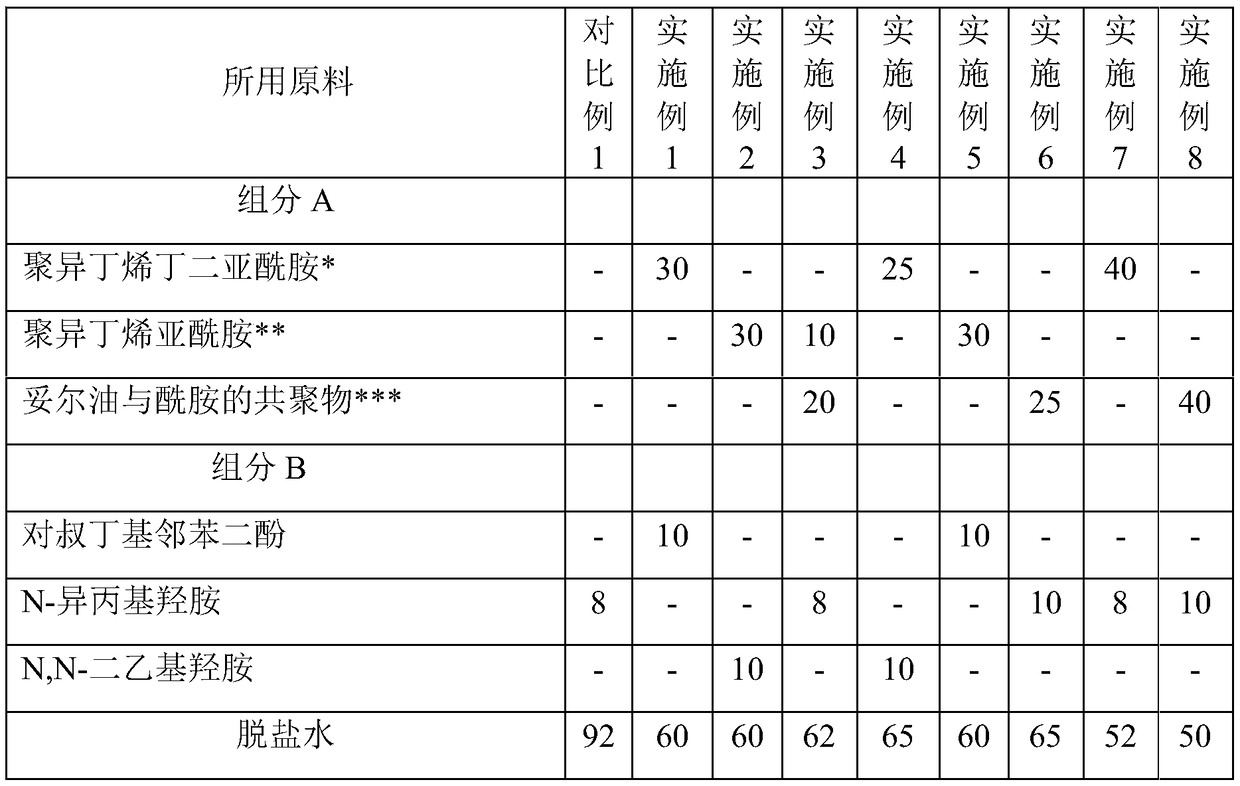

Method used

Image

Examples

Embodiment 9

[0035] Add 100ppm of the dispersed scale inhibitor of Example 1 into the above-mentioned standby mixture, and react under the condition of a residence time of 30min. After the reaction, the mass of the remaining scale sample is measured to be 0.54g.

Embodiment 10

[0037] Add 100ppm of the dispersed scale inhibitor of Example 2 into the above-mentioned standby mixture, and react under the condition of a residence time of 30min. After the reaction, the mass of the remaining scale sample is measured to be 0.59g.

Embodiment 11

[0039] Add 100ppm of the dispersed scale inhibitor of Example 3 into the above-mentioned standby mixture, and react under the condition of a residence time of 60min. After the reaction, the mass of the remaining scale sample is measured to be 0.09g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com