Method for determining solid content of ABS by continuous bulk polymerization process

A determination method and technology of solid content, which can be applied in the direction of removing a certain component and weighing, etc., to solve problems such as affecting the test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

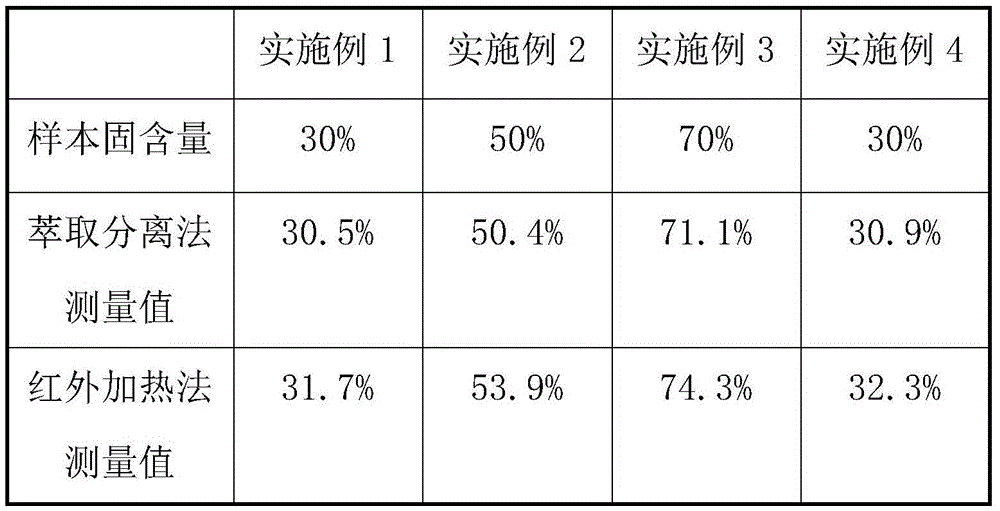

Embodiment 1

[0027] 1 g of a sample with a solid content of 30% was weighed, and 10.1 g of a mixed solvent (5 g of toluene, 5 g of methyl ethyl ketone, 0.1 g of hydroquinone) was added under stirring. After the sample was completely dissolved, the sample solution was added dropwise to 100 g of methanol liquid under strong stirring conditions. After thorough mixing, statically separate layers, separate the polymer phase through a filter, then put the polymer phase and the filter together in an oven, place at 100 ° C for 1 hour, then cool to room temperature to weigh the polymer mass, calculate This gives a solids content of 30.5%.

Embodiment 2

[0029] 1 g of a sample with a solid content of 50% was weighed, and 10.1 g of a mixed solvent (5 g of toluene, 5 g of methyl ethyl ketone, 0.1 g of hydroquinone) was added under stirring. After the sample was completely dissolved, the sample solution was added dropwise to 100 g of methanol liquid under strong stirring conditions. After thorough mixing, statically separate layers, separate the polymer phase through a filter, then put the polymer phase and the filter together in an oven, place at 100 ° C for 1 hour, then cool to room temperature to weigh the polymer mass, calculate This gave a solids content of 50.4%.

Embodiment 3

[0031] 4 g of a sample with a solid content of 70% was weighed, and 50.1 g of a mixed solvent (25 g of toluene, 25 g of methyl ethyl ketone, 0.1 g of hydroquinone) was added under stirring. After the sample was completely dissolved, the sample solution was added dropwise to 500 g of methanol liquid under strong stirring conditions. After thorough mixing, statically separate layers, separate the polymer phase through a filter, then put the polymer phase and the filter together in an oven, place at 100 ° C for 1 hour, then cool to room temperature to weigh the polymer mass, calculate This gave a solids content of 71.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com