Method for preparing styrene-acrylic ester microemulsion

A technology of acrylate and styrene, which is applied in the field of preparation of styrene-acrylate microemulsion, which can solve the problems of high emulsifier dosage, hindering industrial production of styrene microemulsion polymerization, low solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Processing step of the present invention is:

[0012] 1. The monomer styrene is treated with 8% NaOH before feeding, the purpose is to remove the polymerization inhibitor-p-tert-butylcatechol in the monomer;

[0013] 2. Heat the constant temperature water bath to 65°C, then add emulsifier OP-1010~34ml, co-emulsifier DBS3.75~9.0ml, monomer styrene 114ml, crosslinking agent divinylbenzene 0.8~2.0ml, trigger Agent K 2 S 2 o 8 0-25ml, the reaction temperature is controlled at 65-70°C, and the reaction is carried out for 6-8 hours; the reactants are taken out, and analyzed by laser particle size and electron microscope.

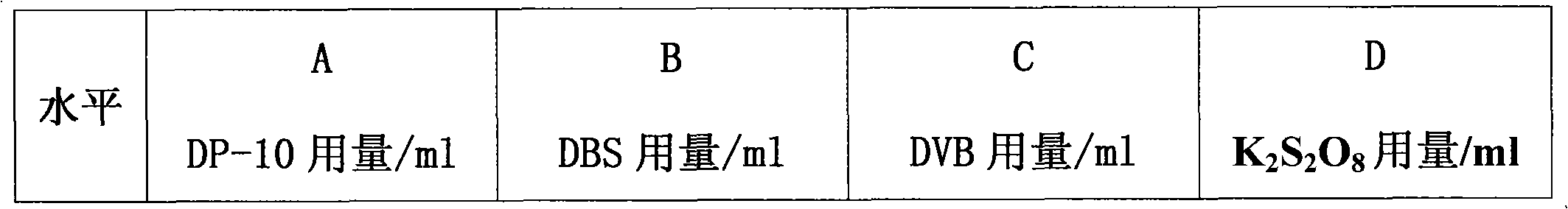

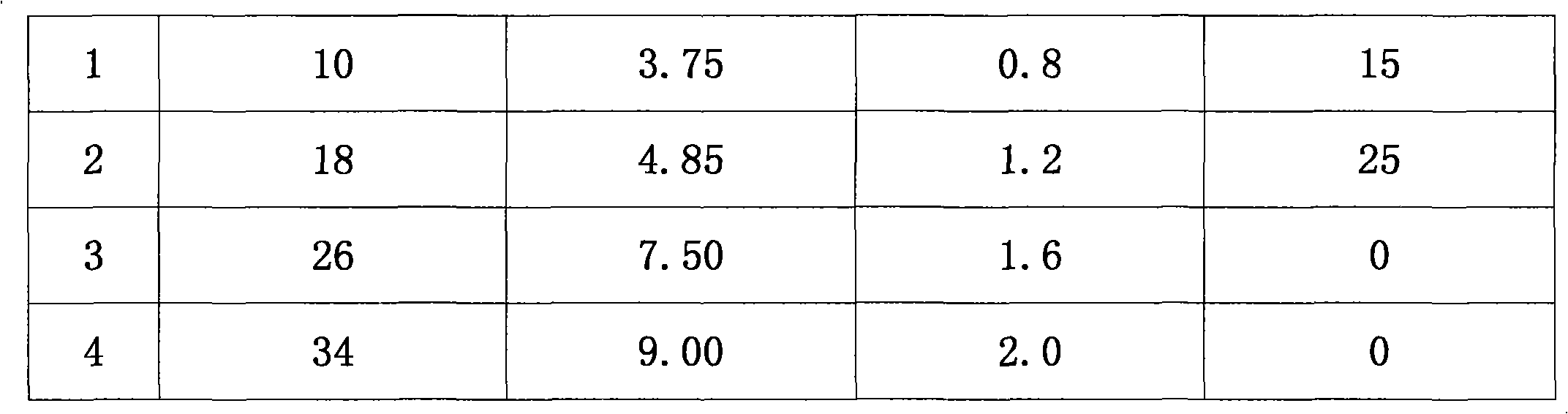

[0014] The present invention chooses to add emulsifier OP-10, auxiliary emulsifier DBS, crosslinking agent divinylbenzene, initiator K 2 S 2 o 8 As a factor affecting the preparation effect of styrene-acrylic ester microemulsion, see Table 1 and Table 2.

[0015] Table 1 Four-factor level table

[0016]

[0017]

[0018] Table 2 The influence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com