A kind of production method of ethylidene norbornene

A technology for the production of ethylidene norbornene, which is applied in the direction of isomerization and hydrocarbon production, can solve the problems of high production cost and low yield of target products, and achieve the effect of increased selectivity and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

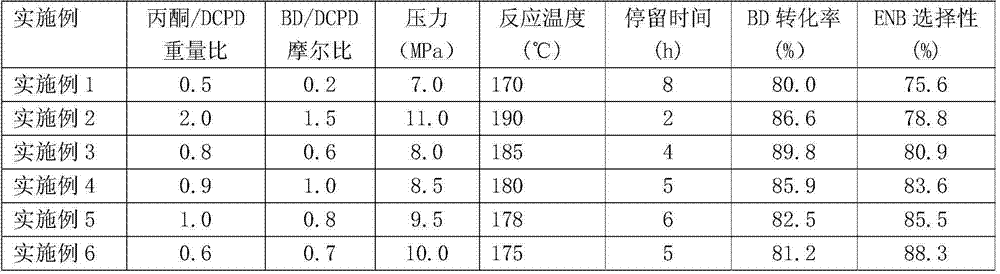

[0024] The reaction is carried out in a tank reactor with a volume capacity of 2 liters. The reactor is equipped with a stirring device, a cooling coil, and an electric heating system is installed outside. Pump the prepared solution of dicyclopentadiene (DCPD), acetone, 1,2-butadiene (BD) and p-tert-butylcatechol (TBC) into the reactor, start stirring, and raise the temperature to the required temperature , and then use the constant pressure valve to adjust the pressure of the reactor to the set pressure to carry out the reaction. After the reaction is finished, it is collected after cooling, sampled and analyzed, and the analysis of the sample adopts the GC method. The collected reaction materials are transferred into a rectification tower with 45 theoretical plates for rectification. The content of the obtained ethylidene norbornene (ENB) product is 99.9%, and the recovered acetone is recycled.

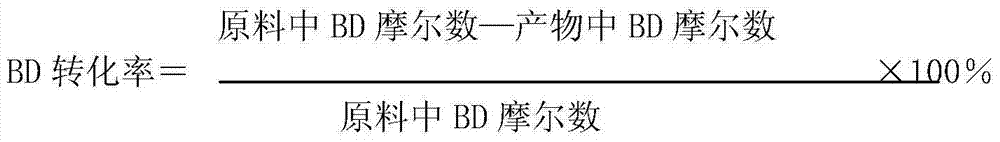

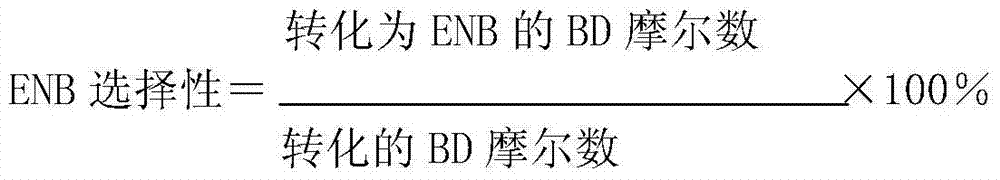

[0025] See Table 1 for the specific reaction conditions of each example, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com