Communication optical cable jacket material for hot and humid areas and preparation method thereof

A technology for communication optical cables and sheathing materials, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of easy damage, poor heat resistance and water resistance, and achieve excellent water resistance and chemical corrosion resistance. properties, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

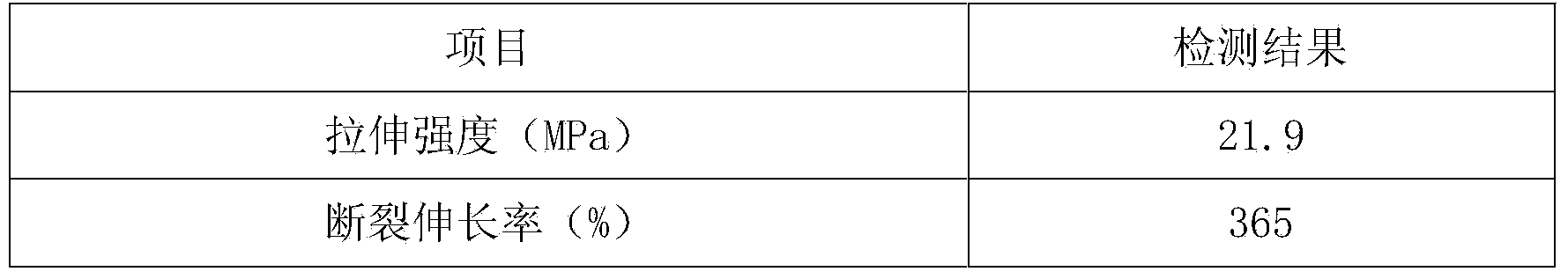

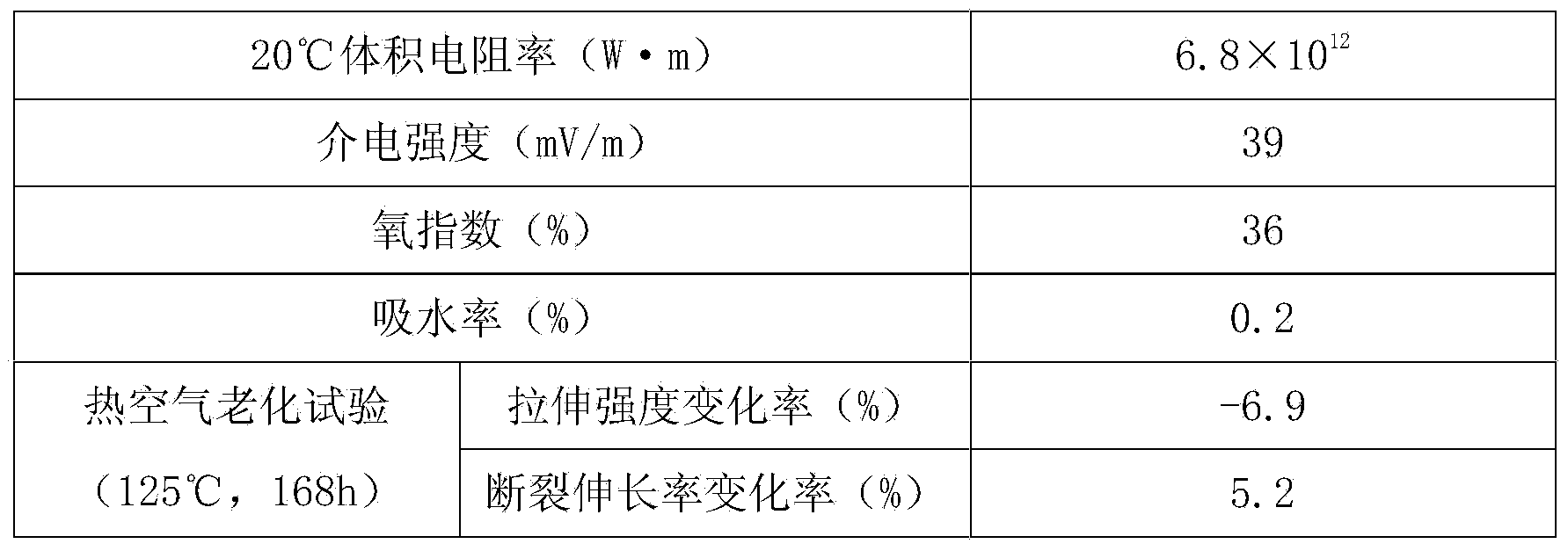

[0012] A communication optical cable sheath material for hot and humid areas, made of the following raw materials (kg): polybutylene terephthalate 46, polyarylether ether nitrile 24, triglycidyl isocyanurate 6, di Benzyl methane bismaleimide 4.5, tetrabasic zinc chromate 3.5, wollastonite powder 18, isobutyltriethoxysilane 3, ethyl-3-aminobutyrylate 5, terephthalic acid di Octyl ester 16, p-tert-butylcatechol 2.5, melamine cyanurate 7, diphenylsilanediol 4, phenol-aralkyl epoxy resin 12, 2-ethyl lead acetate 2, montan wax 6, di Aluminum isobutyl hypophosphite 8;

[0013] The preparation method of the regenerated material is as follows: (1) Take the following raw materials in parts by weight: PVC waste 48, PP waste 36, ABS nozzle material 17, PETG scrap 12, aramid pulp 8, refractory brick shavings 14, fly ash 12. Oil shale slag 8, waste glass powder 6, carbide slag 4, ethylene glycol diglycidyl ether 3.5, butyl acetyl ricinoleate 5, mercaptopropylmethyldimethoxysilane 2, bisph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com