Norbornene production method

A technology for norbornene and a production method, applied in the field of preparing norbornene, can solve the problems of reaction temperature and pressure safety traps, harshness, etc., and achieve the effects of avoiding explosion danger, improving selectivity, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

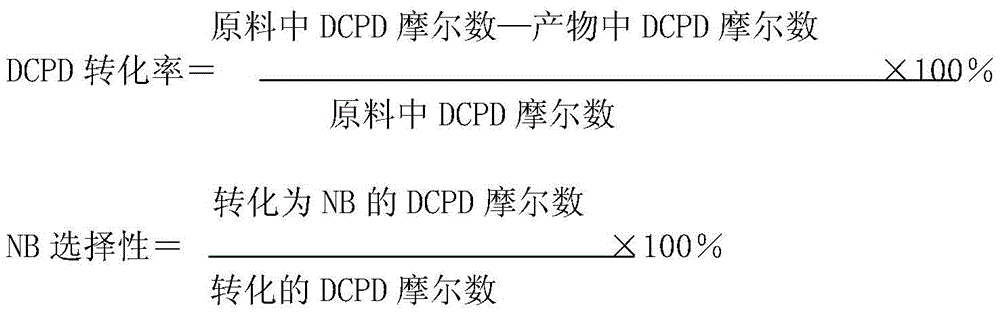

Method used

Image

Examples

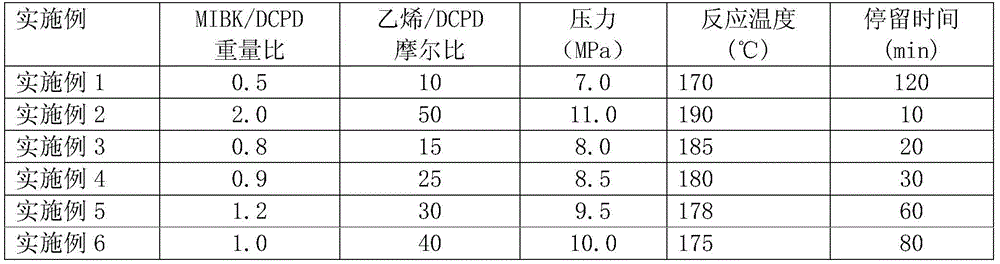

Embodiment 1~6

[0031]The reaction was carried out in two tank reactors connected in series with a volume capacity of 2 liters and 1 liter respectively. The reactor was equipped with a stirring device, a cooling coil, and an electric heating system was installed outside. The prepared dicyclopentadiene (DCPD), solvent methyl isobutyl ketone (MIBK) and polymerization inhibitor (TBC) solution are continuously sent into the first tank reactor from the bottom of the first tank reactor with a pump , After starting the stirring, feed the required part of ethylene gas, and raise the temperature to the required temperature, and then use the constant pressure valve to adjust the pressure of the reactor to the set pressure, and the reaction liquid of the first tank reactor passes through the reactor The discharge port on the upper side is continuously discharged into the second tank reactor through the bottom of the second tank reactor, and the reaction continues under the set conditions, and the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com