Enzymatic fermented black tea beverage and preparation method thereof

A technology of enzymatic fermentation and black tea, applied in the field of food and beverage, can solve problems such as turbidity and aggregation, achieve clear tea soup, shorten the production cycle, and solve the effects of unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

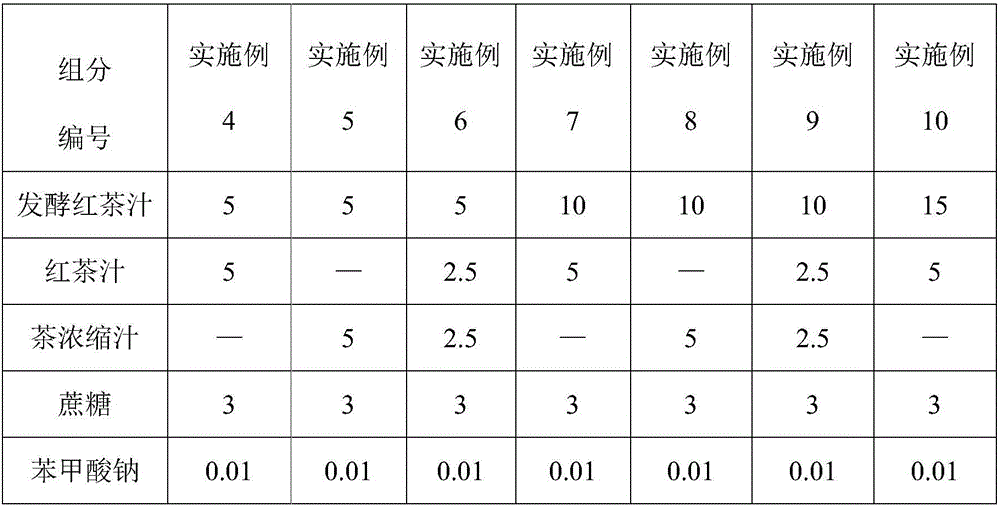

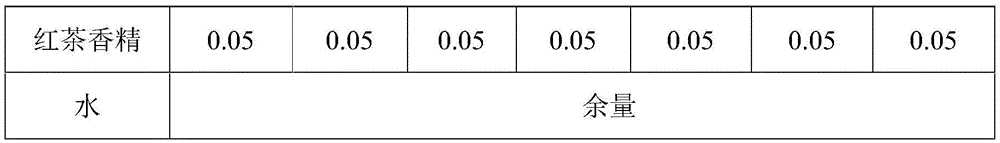

Examples

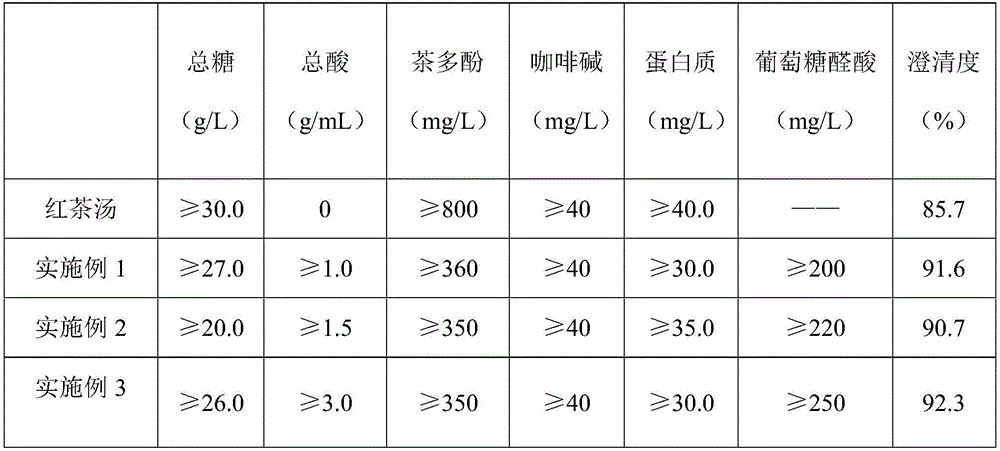

Embodiment 1

[0022] The enzymatically fermented black tea juice is prepared by step-by-step fermentation. In terms of weight concentration percentage, 50-100% black tea soup and 1-30% sucrose are mixed, sterilized at 80-100°C for 5-30min, and then cooled To room temperature, add 0.1-10% Lactobacillus plantarum and 5-50ppm clarified enzyme preparation to statically anaerobically ferment at a temperature of 25-40°C, ferment for 12-72h, and stop when the alcohol content reaches 0.5-10% (vol). Ferment, filter and sterilize at 80-100°C for 5-30min, cool to room temperature, add 0.1-20% Lactobacillus plantarum and 5-50ppm clarified enzyme preparation, and ferment for 24-144h under dynamic ventilation and stirring at a temperature of 25-40°C. When the total acid is ≥3.0g / 100ml or the fermentation exceeds 144 hours, stop the fermentation, filter and sterilize at 80-100°C for 5-30 minutes, filter to obtain enzymatically fermented black tea juice, and store at low temperature or room temperature belo...

Embodiment 2

[0024] The enzymatically fermented black tea juice is prepared by step-by-step fermentation. In terms of weight concentration percentage, 50-100% black tea soup and 1-30% sucrose are mixed, sterilized at 80-100°C for 5-30min, and then cooled to room temperature, add 0.1-10% Brady's yeast and 5-50ppm clarified enzyme preparation to ferment aerobically at a temperature of 25-40°C, ferment for 12-72h, when the alcohol content reaches 0.5-10% (vol), Terminate fermentation, filter and sterilize at 80-100°C for 5-30min, cool to room temperature, add 0.1-20% Acetobacter and 5-50ppm clarified enzyme preparation, and ferment with dynamic ventilation and stirring at 25-40°C for 24-144h, when When the total acid is ≥3.0g / 100ml or the fermentation exceeds 144 hours, stop the fermentation, filter and sterilize at 80-100°C for 5-30 minutes, filter to obtain enzymatically fermented black tea juice, and store at low temperature or room temperature below 10°C.

Embodiment 3

[0026] The enzymatically fermented black tea juice is prepared by step-by-step fermentation. In terms of weight concentration percentage, 50-100% black tea soup, 1-30% sucrose, 0.1-5.0% whey protein or skim milk powder are mixed evenly, and 80% Sterilize at -100°C for 5-30 minutes, then cool to room temperature, add 0.1-10% brewer’s yeast and 5-50ppm clarified enzyme preparations, culture at a constant temperature of 25-40°C, ferment for 12-72h, when the alcohol content reaches 0.5 When -10% (vol), stop the fermentation, filter and sterilize at 80-100°C for 5-30min, cool to room temperature, add 0.1-20% Acetobacter and 5-50ppm clarified enzyme preparations and dynamically at a temperature of 25-40°C Ventilation and stirring fermentation for 24-144 hours, when the total acid ≥ 3.0g / 100ml or the fermentation exceeds 144 hours, stop the fermentation, filter and sterilize at 80-100 ° C for 5-30 minutes, filter to obtain enzymatic fermentation black tea juice, at a low temperature b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com