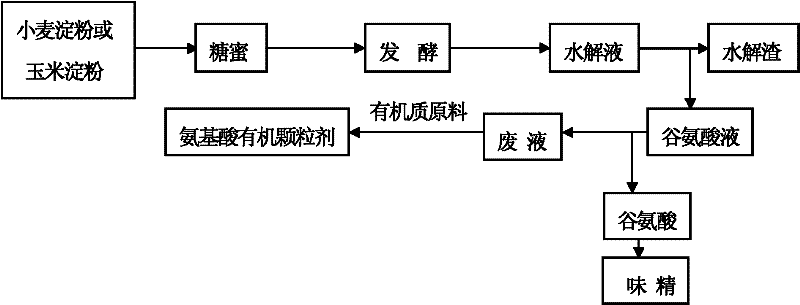

Production method of granular bioorganic fertilizer

A technology of bio-organic fertilizer and production method, which is applied in the field of amino acid organic granules to produce high-efficiency and environmentally-friendly granular bio-organic fertilizers, which can solve the problems of increased soil diseases, difficulty in batch production, and increased production costs, and achieve improved product quality and easy dissolution , the effect of thorough governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

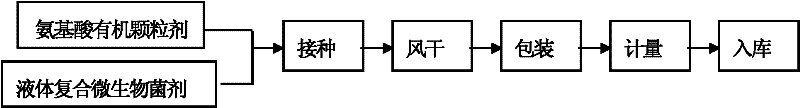

Method used

Image

Examples

Embodiment 1

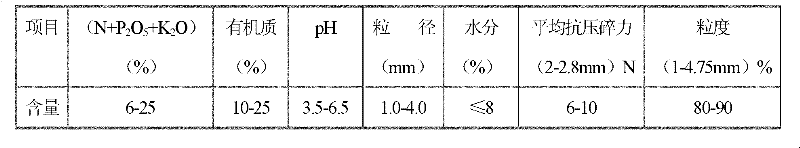

[0038] 1. Spray and granulate the amino acid waste liquid in the production process of monosodium glutamate into organic granules. When spraying and granulating, add humic acid with a weight ratio of 10% per ton of finished bio-organic fertilizer. The basic properties of humic acid See Table 2, and see Table 3 for the properties of the organic granules after addition.

[0039] Table 2: Basic properties of humic acid

[0040] project

Organic matter (%)

pH

Fineness (mesh)

Humic acid (%)

Moisture (%)

Miscellaneous bacteria rate (%)

content

56.6

5.7

60

37.3

25.6

13.8

[0041] Table 3: Basic properties of amino acid organic granules

[0042]

[0043] Preparation of liquid bacterial agent: Bacillus subtilis, Bacillus megaterium and Bacillus mucilagimosus krassilm were fermented separately by fermentation equipment, and the three single bacterial solutions were mixed in a ratio of 2:1 : 1 ratio mixes, m...

Embodiment 2

[0047] The amino acid waste liquid in the monosodium glutamate production process is sprayed and granulated, and monoammonium phosphate, borax and 18% humic acid accounting for the weight ratio of the finished bio-organic fertilizer are added during the granulation process, and the organic matter content of the obtained organic granules is 30.4 %.

[0048] 1. Preparation of liquid bacterial agent: Bacillus subtilis (Bacillus subtilis) and Bacillus megaterium (Bacillus megaterium) are fermented and produced separately by fermentation equipment, and the two single bacterial liquids are mixed according to the ratio of 1:1, so that the two bacterial liquids after mixing The total number of effective viable bacteria in the mixed liquid compound microbial agent reached 45.6×10 8 pcs / g.

[0049] 2. Turn on the mixer, slowly and evenly add the organic granules, so that the material flows forward continuously and evenly, and in the rotating mixer, use a plunger pump to evenly spray th...

Embodiment 3

[0052] The amino acid waste liquid in the monosodium glutamate production process is sprayed and granulated, and 8% humic acid and 8% peat that account for the weight ratio of the finished bio-organic fertilizer are added in the granulation process, and the organic matter content of the obtained organic granules is 26 %.

[0053] 1. Preparation of liquid bacterial agent: Bacillus subtilis and Bacillus mucilagimosus krassilm are fermented and produced separately by fermentation equipment, and the two single bacterial solutions are mixed according to the ratio of 2:1, so that after mixing The total number of effective viable bacteria in the liquid composite microbial agent mixed with the two bacteria liquids reached 40.6×10 8 pcs / g.

[0054] 2. Turn on the mixer, slowly and evenly add the organic granules, so that the material flows forward continuously and evenly, and in the rotating mixer, use a plunger pump to evenly spray the bacterial solution on the surface of the organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com