One-way continuous carbon fiber reinforced polyether-ether-ketone composite material and preparation method thereof

A polyetheretherketone multifilament and polyetheretherketone technology, which is applied in the field of unidirectional continuous carbon fiber reinforced polyetheretherketone composite material and its preparation, can solve the difficulty of three-dimensional weaving technology, the carbon fiber is easily worn, and the composite material reaches Less than and other problems, to improve the dipping effect, reduce the dipping distance, reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

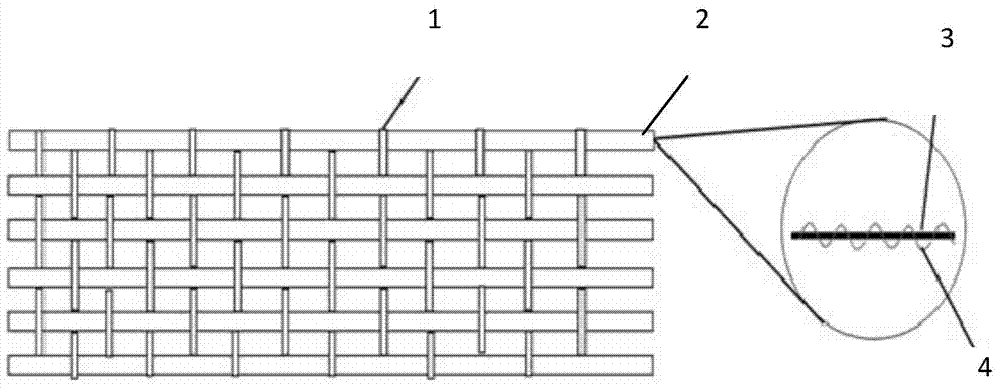

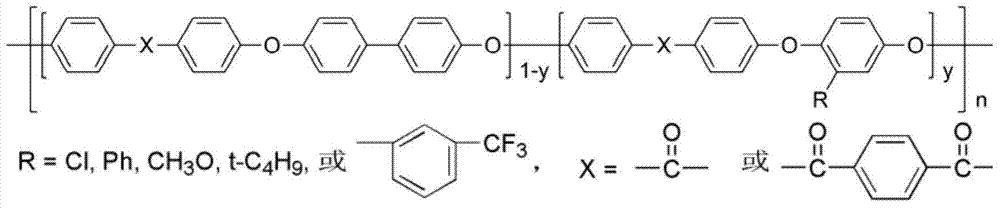

Method used

Image

Examples

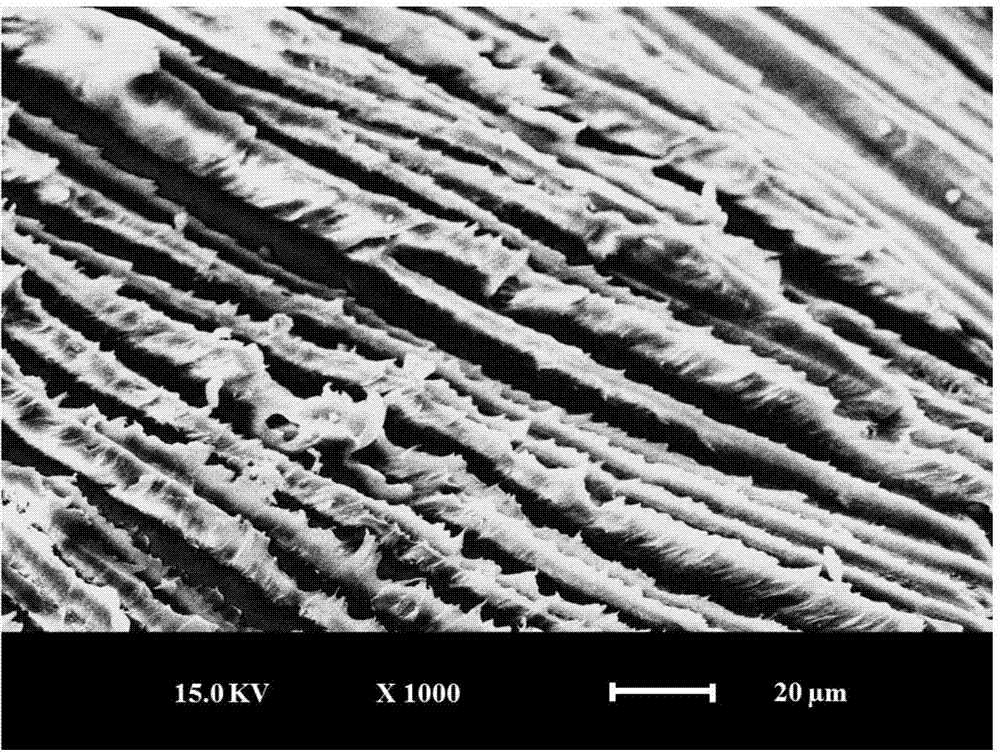

Embodiment 1

[0026] Select melt index as 12g / 10min spinning grade polyether ether ketone resin special material (produced by Changchun Jida Special Plastic Engineering Research Co., Ltd.) to make polyether ether ketone fiber with a fineness of 150tex by melt spinning (spinning process Condition control: the temperature range of each heating zone of the spinning extruder, the first zone is 100°C, the second zone is 370°C, the third zone is 400°C, the fourth zone is 410°C, the fifth zone is 415°C, the sixth zone is 430°C, and the seventh zone is 430°C. Zone 425°C, Zone 8 420°C, spinning speed 150m / min, filament draw ratio 1.5:1, post-stretch temperature 230°C), the polyether ether ketone fiber is passed through according to the carbon fiber volume content of 45%. A fancy twister (provided by Tianjin University of Technology) was evenly wrapped around 3K polyacrylonitrile-based carbon fibers (produced by Toho Tenax, Japan, with a fineness of 200tex) to obtain a hybrid fiber bundle, with a twis...

Embodiment 2

[0028]Select melt index as 22g / 10min spinning grade polyetheretherketone resin special material (produced by Changchun Jida Special Plastic Engineering Research Co., Ltd.) to make polyetheretherketone fiber with a fineness of 44tex by the method of melt spinning (spinning process Condition control: the temperature range of each heating zone of the spinning extruder, the first zone is 100°C, the second zone is 370°C, the third zone is 400°C, the fourth zone is 410°C, the fifth zone is 415°C, the sixth zone is 420°C, and the seventh zone is 420°C. Zone 415°C, Zone 8 410°C, spinning speed 150m / min, filament draw ratio 2.1:1, post-stretch temperature 220°C), the polyether ether ketone fiber is made according to the carbon fiber volume content of 55%. Through fancy twisting machine (provided by Tianjin Polytechnic University) uniformly wrapped in 3K polyacrylonitrile-based carbon fiber (produced by Japan Toho Tenax company, fineness is 200tex) to make hybrid fiber bundle, its twist ...

Embodiment 3

[0030] As described in Example 1, only the special material for spinning grade polyetheretherketone resin (produced by Changchun Jida Special Plastic Engineering Research Co., Ltd.) with a melt index of 44g / 10min was selected to obtain a polyether ether ketone resin with a fineness of 29tex by melt spinning. Ether ether ketone fiber (spinning process condition control: the temperature range of each heating zone of the spinning extruder, the first zone is 100°C, the second zone is 360°C, the third zone is 400°C, the fourth zone is 410°C, the fifth zone is 415°C ℃, 420℃ in the sixth zone, 415℃ in the seventh zone, 410℃ in the eighth zone, the spinning speed is 160m / min, the drawing ratio of the filament is 2.5:1, and the post-stretching temperature is 210℃), according to the carbon fiber volume content of 55 % The polyetheretherketone fiber is uniformly wrapped on the outside of 3K polyacrylonitrile-based carbon fiber (produced by Toho Tenax, Japan, fineness is 200tex) through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com