Fabric and production method thereof

A production method and fabric technology, applied in the field of textiles, can solve the problems of increased operation difficulty, lack of cotton feeling, increased environmental pollution, etc., and achieve the effects of good wear resistance, low environmental load and simple process

Inactive Publication Date: 2011-01-12

TORAY FIBER RES INST(CHINA) CO LTD

View PDF6 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This increases the investment cost and dye consumption, increases the difficulty of operation, and increases the pollution to the environment.

[0004] Chinese patent CN200810063649.2 discloses a kind of durable DTY two-color polyester filament, which mainly adopts the method of network to simply compound the raw materials of two kinds of different-color dyeing effects, although the fabric made by it meets the two-color effect denim Features, but feel hard, lack of cotton feeling

Method used

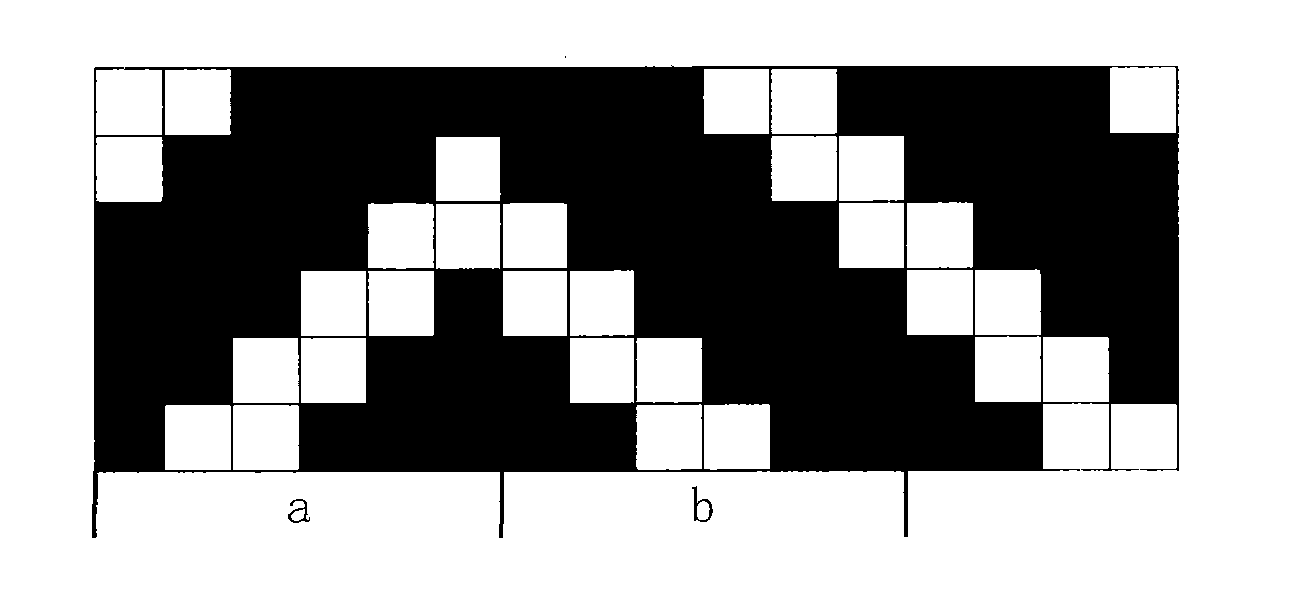

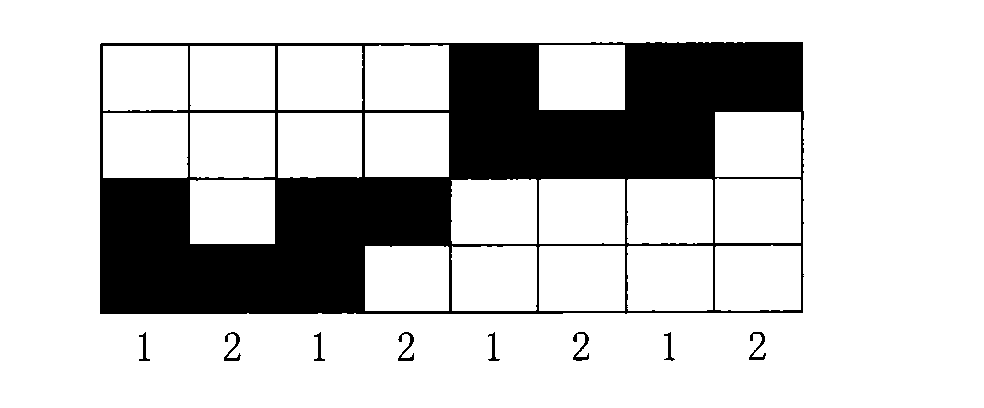

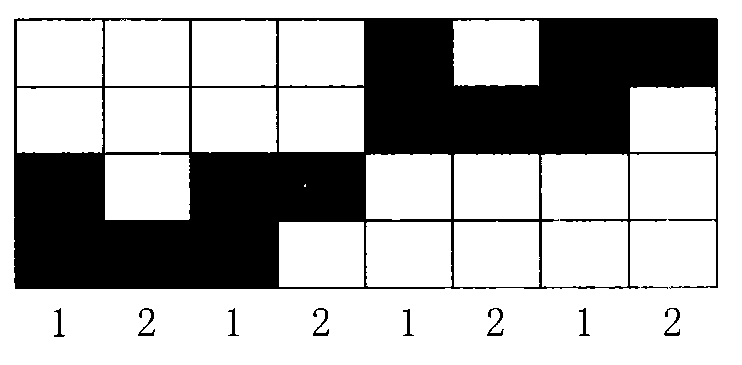

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a fabric and a production method thereof. All or partial warps forming the fabric are air-texturing composite yarns, and the air-texturing composite yarns are manufactured by feeding modified polyester pre-orientated yarns serving as decorative yarns and polyester full-drawn yarns serving as core yarns into an air-texturing nozzle and performing thermal treatment under the action of airflow. In the production process of the fabric, variable tissues of plain weave, twill weave, plain weave and twill weave or dual tissues taking the above tissues as surface tissues are adopted. The prepared fabric has super indigo effect, double-color effect and good abrasion resistance and wrinkle resistance.

Description

technical field [0001] The invention relates to a textile, in particular to a fabric and a production method thereof. Background technique [0002] Denim fabrics, which have been popular for many years, have been loved by people for their rough, bold and unrestrained characteristics. In recent years, various special denim fabrics have appeared on the market, such as super indigo dyed denim fabrics and weft stretch denim fabrics. Cotton is still used as the main material. Because cotton fabric itself has some insurmountable shortcomings, such as easy to wrinkle and poor dimensional stability, although it can be improved to a certain extent after certain post-processing, the durability is poor and the cost will increase. [0003] "Super Indigo" dyed denim is widely welcomed by consumers because of its bright color effect, because the dyeing depth of "Super Indigo" dyed denim is more than 60% higher than that of conventional traditional denim dyeing, so the indigo concentration...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D15/00D03D13/00D02G1/16D06P3/52D06P3/54D06M11/38D03D15/283

Inventor 徐建锋蔡东照

Owner TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com