Light conveying belt and preparation method thereof

A light conveyor belt and woven fabric technology, applied in conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems of not being able to meet high-quality printed products, unstable dimensions of light conveyor belts, and large elongation of the belt body , to improve the overall tensile and peeling properties, reduce weft shrinkage, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

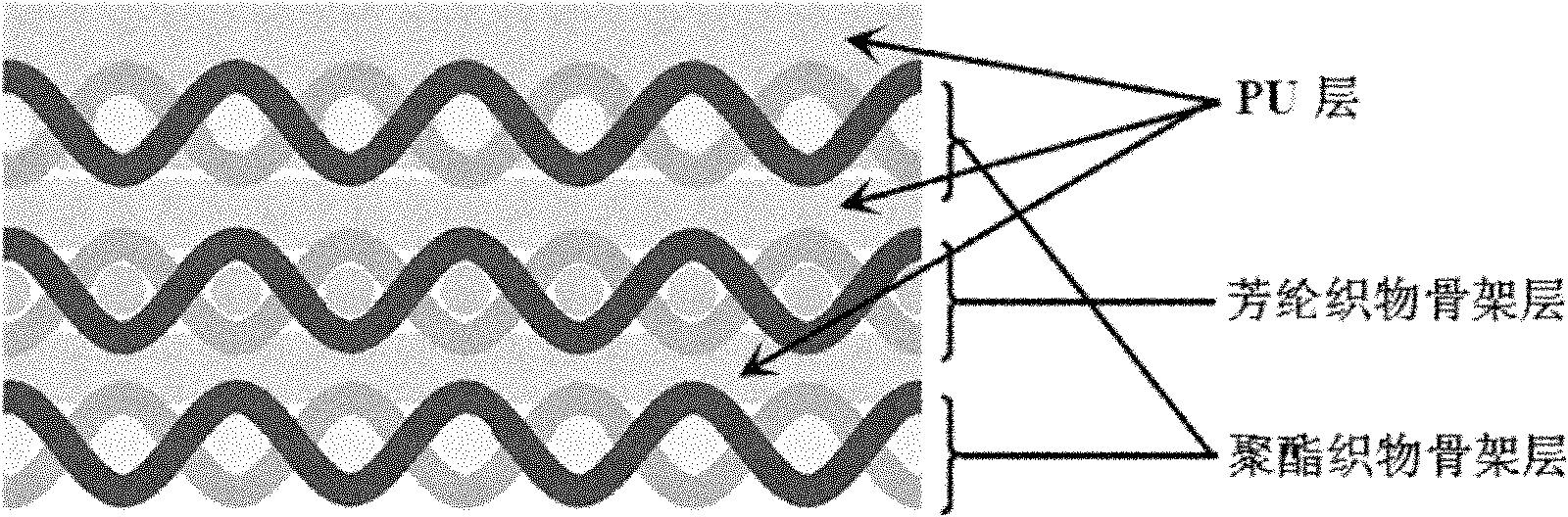

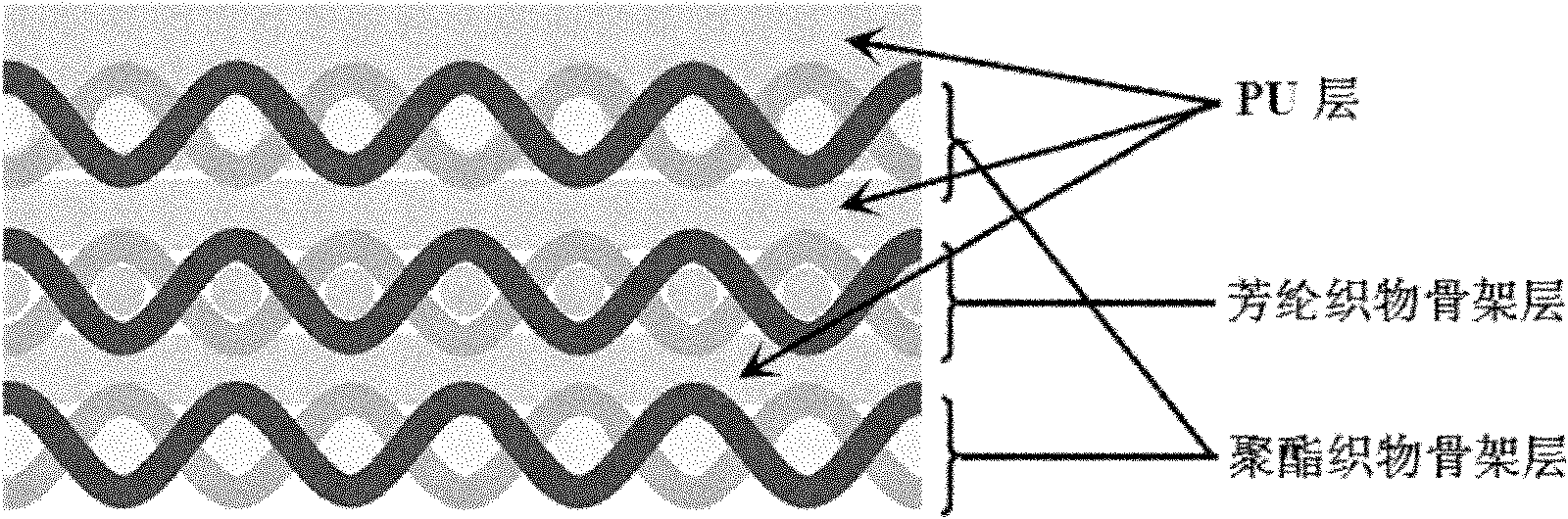

[0044] The invention is suitable for the fields with complex service conditions and high requirements on the longitudinal strength and dimensional stability of light conveyor belts, such as dyeing, finishing and printing, and the strength range under 1% longitudinal elongation is 40-80N / mm. The warp yarn of Kevlar woven fabric is 1000D Kevlar low-twisted filament, including Kevlar29 and Kevlar49. The weft yarn is 1000D ultra-low shrinkage polyester multifilament. The basic structure used is plain weave with a width of 50cm. The warp yarn of the polyester woven fabric is 1000D ultra-low shrinkage polyester multifilament, and the weft yarn is 0.3mm polyester monofilament.

[0045] A light conveyor belt, comprising: Kevlar woven fabric, polyester woven fabric and polyurethane covering rubber layer, wherein Kevlar woven fabric is used as the middle skeleton layer, and two layers of polyester woven fabric are used as the first skeleton layer skeleton material and the bottom skeleton...

Embodiment 2

[0051] A method for preparing a light conveyor belt, comprising:

[0052] (1) Kevlar woven fabric

[0053] The warp yarn is 1000D Kevlar49, the weft yarn is 1000D ultra-low shrinkage polyester multifilament, and the basic structure is plain weave;

[0054] (2) Sizing treatment of Kevlar woven fabric

[0055] Apply glue to the above fabric, and set it at 180°C for 2 to 3 minutes under tension, and observe the gloss and flatness of the glue;

[0056] (3) Polyester woven fabric

[0057] Polyester woven fabric skeleton material, warp and weft density 56 / 26 threads / inch;

[0058] (4) Preparation of three cloth and three glue finished products

[0059] Coating material: PU (polyurethane) primer glue (VP 6%, PU glue, L755%); PU powder, conductive PU;

[0060] Kevlar woven fabric PU primer after above-mentioned finalizing;

[0061] The polyester woven fabric is heated and pre-shaped under tension conditions, so that the temperature of the cloth surface reaches 180°C (pre-setting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com