Concave-convex jacquard cloth and manufacturing method thereof

A technology of jacquard cloth and raised parts is applied in the field of concave-convex jacquard cloth and its manufacturing, which can solve the problems of lack of three-dimensional effect, and achieve the effect of distinct and prominent three-dimensional effect, strong three-dimensional effect, and obvious concave-convex effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

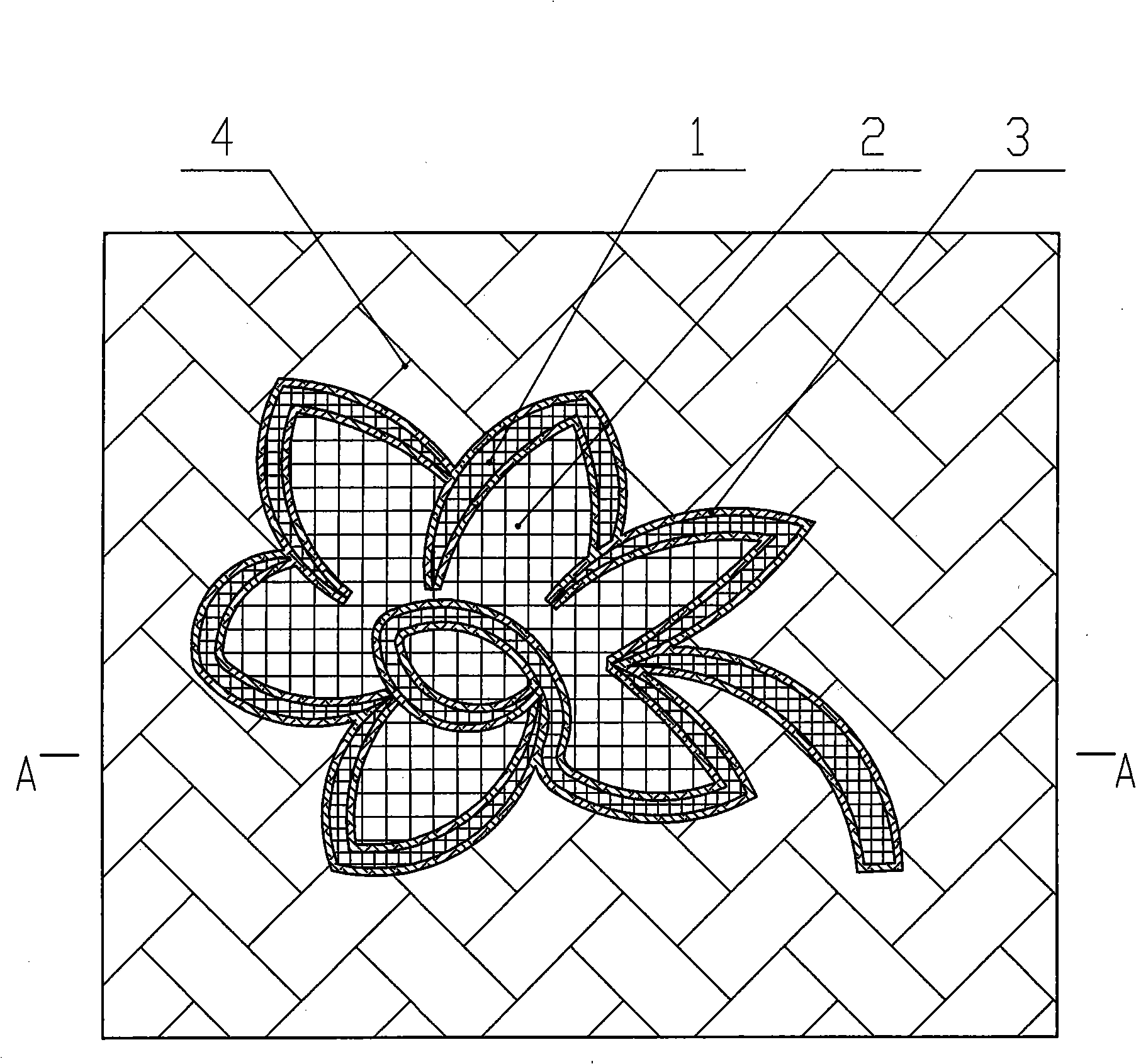

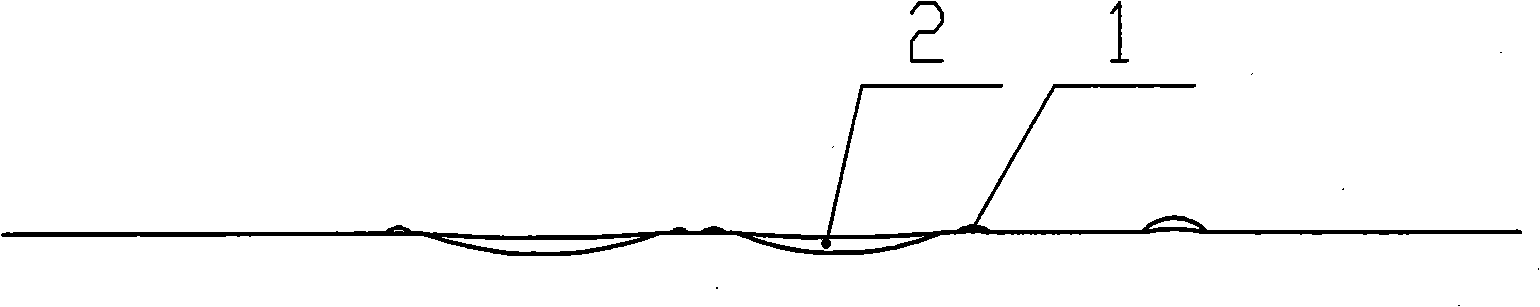

[0018] Such as figure 1 and figure 2 The concave-convex jacquard cloth of the present invention shown has a concave-convex pattern on the surface of the fabric, the warp yarn of the fabric is 40 cotton yarns, and there are two colors of black and white, the weft yarn is cotton yarn and elastic yarn, and the cotton weft yarn is 16 black cotton yarns. The elastic weft yarn is cotton yarn + spandex yarn, the count is 16+70D, and the color is white. The convex part 1 and the concave part 2 of the pattern are plain weave weave, and the surface texture of the convex part 1 is black warp yarn and black weft yarn. , The lower weave is white warp and white weft interweaving, the surface weave of recessed part 2 is white warp and white weft interweaving, the lower weave is black warp and black weft interweaving, and the surrounding of convex part 1 and concave part 2 is frame weave 3. Border weave 3 adopts dobby weave, and the rest of the fabric 4 is a flower weave in which two warps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com