Recognition method for woven fabric structure

A technology of organizational structure and identification method, applied in image data processing, instrumentation, calculation, etc., can solve the problems of non-vertical interweaving, segmentation effect, cumbersome process, etc., and achieve the effect of small calculation amount, high accuracy, and good identification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

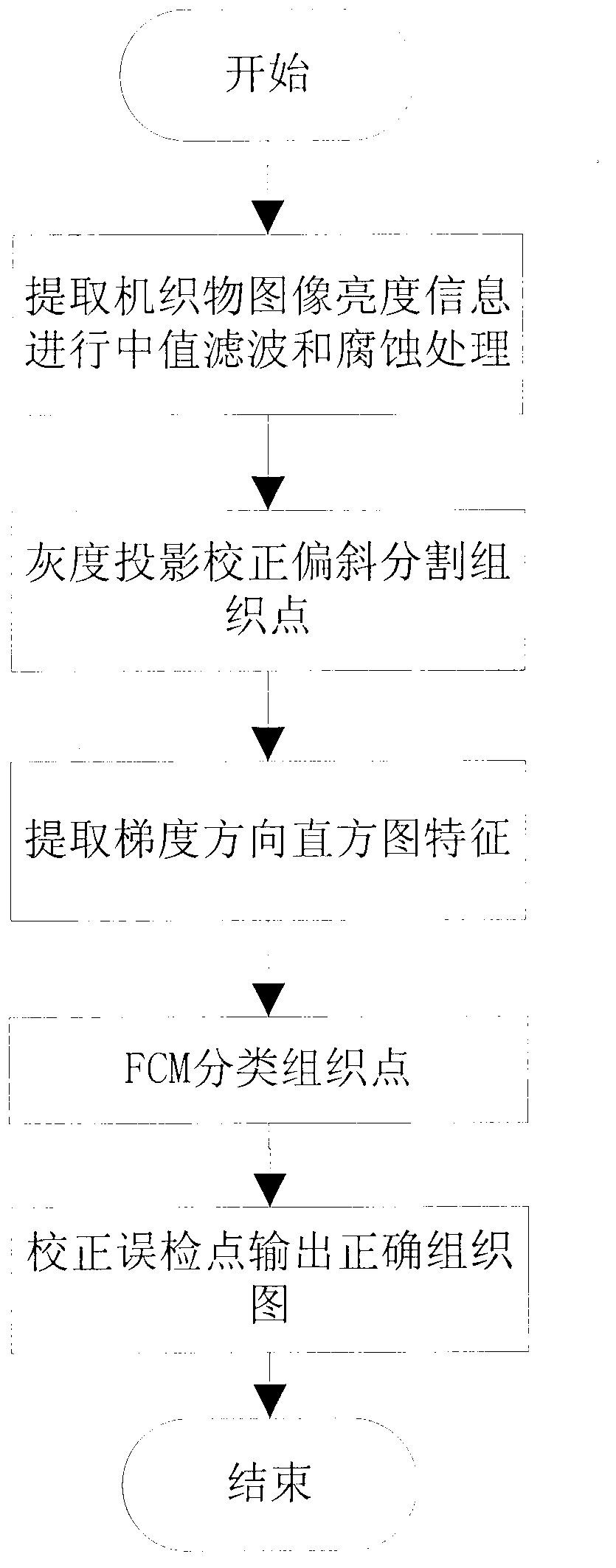

[0026] Process flow of the present invention such as figure 1 As shown, the method first uses median filtering and erosion to preprocess the fabric brightness image, and then uses gray projection to correct the skew existing in the interweaving of warp and weft yarns. At the same time, the fabric image is divided into several weave points. Gradient direction histogram features are extracted from the points, and the improved FCM algorithm is used to classify the weave points. Finally, according to the periodic statistical classification results of the fabric structure, the false detection points are corrected, and the correct weave map is output. The specific implementation process of the technical solution of the present invention will be described below in conjunction with the accompanying drawings.

[0027] 1. Image acquisition and preprocessing

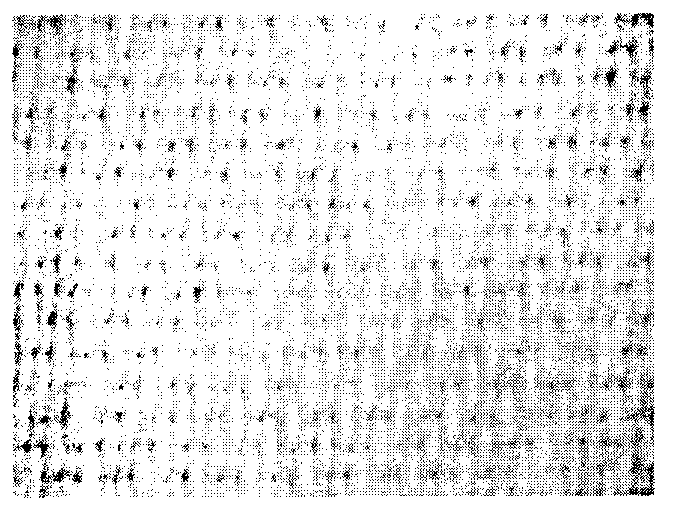

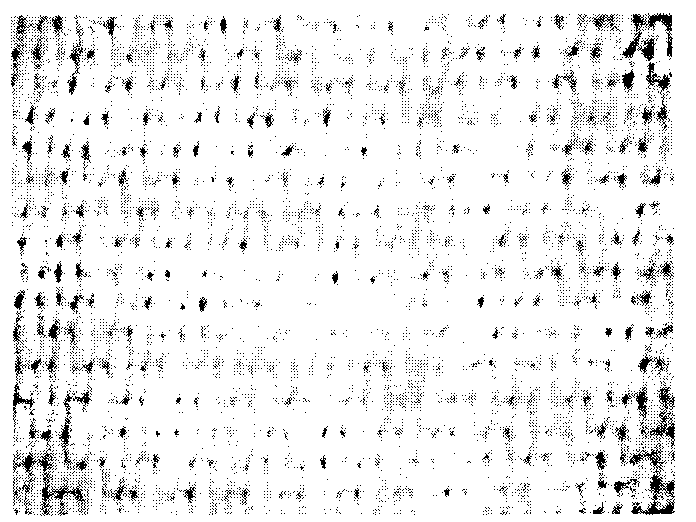

[0028] Obtain a clear and flawless reflection image of the fabric surface, keeping the weft yarns level (e.g. figure 2 ), extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com