Non-equilibrium liquid condition composite pulse plasma polishing method

A technology of polishing liquid and aqueous solution, applied in the field of polishing treatment of metal materials and ion polishing, can solve the problems of difficult mechanical polishing of workpieces, high labor intensity of workers, high power consumption, etc., to avoid surface ablation of workpieces, process Easy to control, good mirror effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Workpiece to be processed: 304 stainless steel sheet

[0044] The preparation polishing liquid is: the concentration of formula A is 3% (NH 4 ) 2 SO 4 Aqueous solution, formula B concentration is 1% ammonium citrate aqueous solution, formula A and formula B are mixed, solution temperature is 90 ℃.

[0045] Eight identical 304 stainless steel sheets were divided into two groups, and polished under different conditions by direct current and pulse respectively:

[0046] DC 1: voltage 200V, temperature 90°C, time 2 minutes.

[0047] DC 2: voltage 250V, temperature 90°C, time 2 minutes.

[0048] DC 3: voltage 300V, temperature 90°C, time 2 minutes.

[0049] DC 4: voltage 350V, temperature 90°C, time 2 minutes.

[0050] Pulse 1: voltage 200V, temperature 90°C, time 2 minutes, frequency 10KHz, duty cycle 50%.

[0051] Pulse 2: voltage 250V, temperature 90°C, time 2 minutes, frequency 10KHz, duty cycle 50%.

[0052] Pulse 3: voltage 300V, temperature 90°C, time 2 minute...

Embodiment 2

[0057] Workpiece to be processed: 304 stainless steel sheet

[0058] Prepare the polishing liquid as: the concentration of component A is 6% (NH 4 ) 2 SO 4 Aqueous solution, the concentration of component B is a mixed aqueous solution of 2% EDTA and 1% sodium oxalate, component A and component B are mixed, and the solution temperature is 95°C.

[0059] Four identical 304 stainless steel sheets were divided into two groups, and polished under different conditions with DC pulse and composite electric pulse respectively:

[0060] DC pulse 1: voltage 280V, frequency 80KHz, duty cycle 95%, time 2 minutes.

[0061] DC pulse 2: voltage 350V, frequency 80KHz, duty cycle 95%, time 2 minutes.

[0062] Composite pulse 1: Positive pulse voltage 280V, frequency 80KHz, duty cycle 95%, negative pulse voltage 100V, time 2 minutes.

[0063] Composite pulse 2: Positive pulse voltage 350V, frequency 80KHz, duty cycle 95%, negative pulse voltage 100V, time 2 minutes.

[0064] The above-ment...

Embodiment 3

[0068] Workpieces to be treated: white copper (containing 7% nickel), titanium

[0069] Prepare the polishing liquid as follows: the concentration is 1% (NH 4 ) 2 SO 4 And concentration is 3% ammonium citrate aqueous solution, solution temperature 90 ℃.

[0070] Under DC pulse and compound pulse treatment respectively:

[0071] DC pulse: voltage 350V, frequency 0.5KHz, duty cycle 50%, time 2 minutes.

[0072] Composite pulse 2: Positive pulse voltage 350V, frequency 0.5KHz, duty cycle 50%, negative pulse voltage 100V, time 2 minutes.

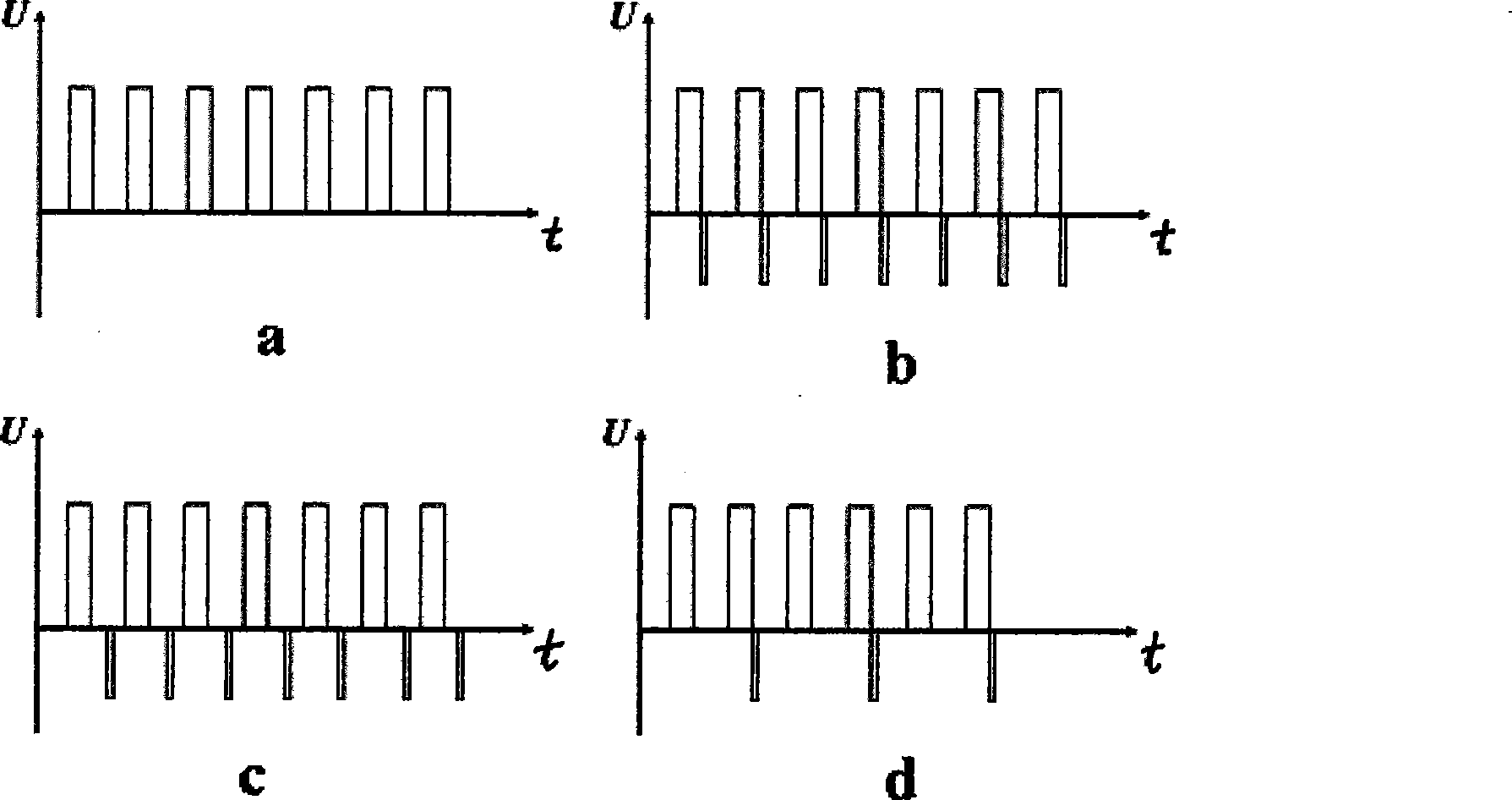

[0073] The above-mentioned composite electric pulse adopts the waveform in the accompanying drawing d, wherein m:n=2:1.

[0074] Table 3 Comparison of pulse polishing and compound electric pulse polishing

[0075] Cupronickel

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com