Feeding mechanism of crusher

A technology of feeding mechanism and pulverizer, which is applied in the direction of grain processing, etc., can solve the problems of losing the chance of crushing and crushing, the material is easy to form a bridge arch, and prolonging the crushing time, so as to achieve a good crushing effect, increase the direction vector difference, and ensure the quality of the material volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

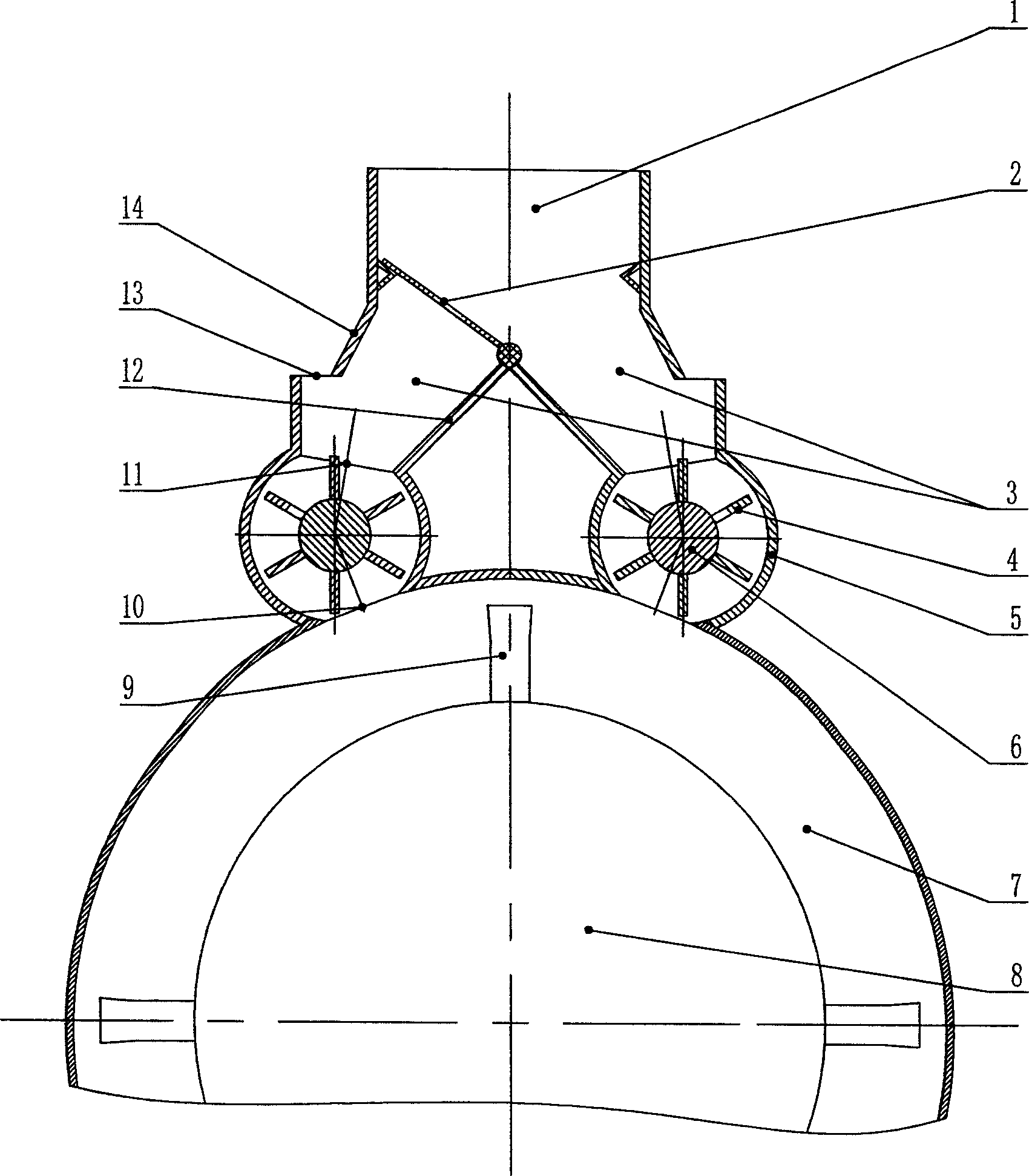

[0012] As shown in the figure, it is the feeding mechanism of the pulverizer, including the feed port 1, which is provided with a tangential flow channel 3 composed of a housing 14 and a slide plate 12 and inclined to the side of the crushing chamber 7. The mouth of the flow channel 3 is provided with a feed baffle 2 that can cover the tangential flow channel 3, and the end of the tangential flow channel 3 is provided with a horizontal cylindrical shell 5, and the upper and lower sides of the cylindrical shell 5 Axial openings 10 and 11 are respectively provided, and the length of the axial openings should be compatible with the length of the hammer blade 9 and the rotor 8, and generally should be the same length; The ends of the road 3 are connected, and the axial opening 10 located on the lower side of the cylindrical shell 5 is arranged on the upper side of the crushing chamber 7; the cylindrical shell 5 is provided with a feeding wheel matched with the cylindrical shell 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com