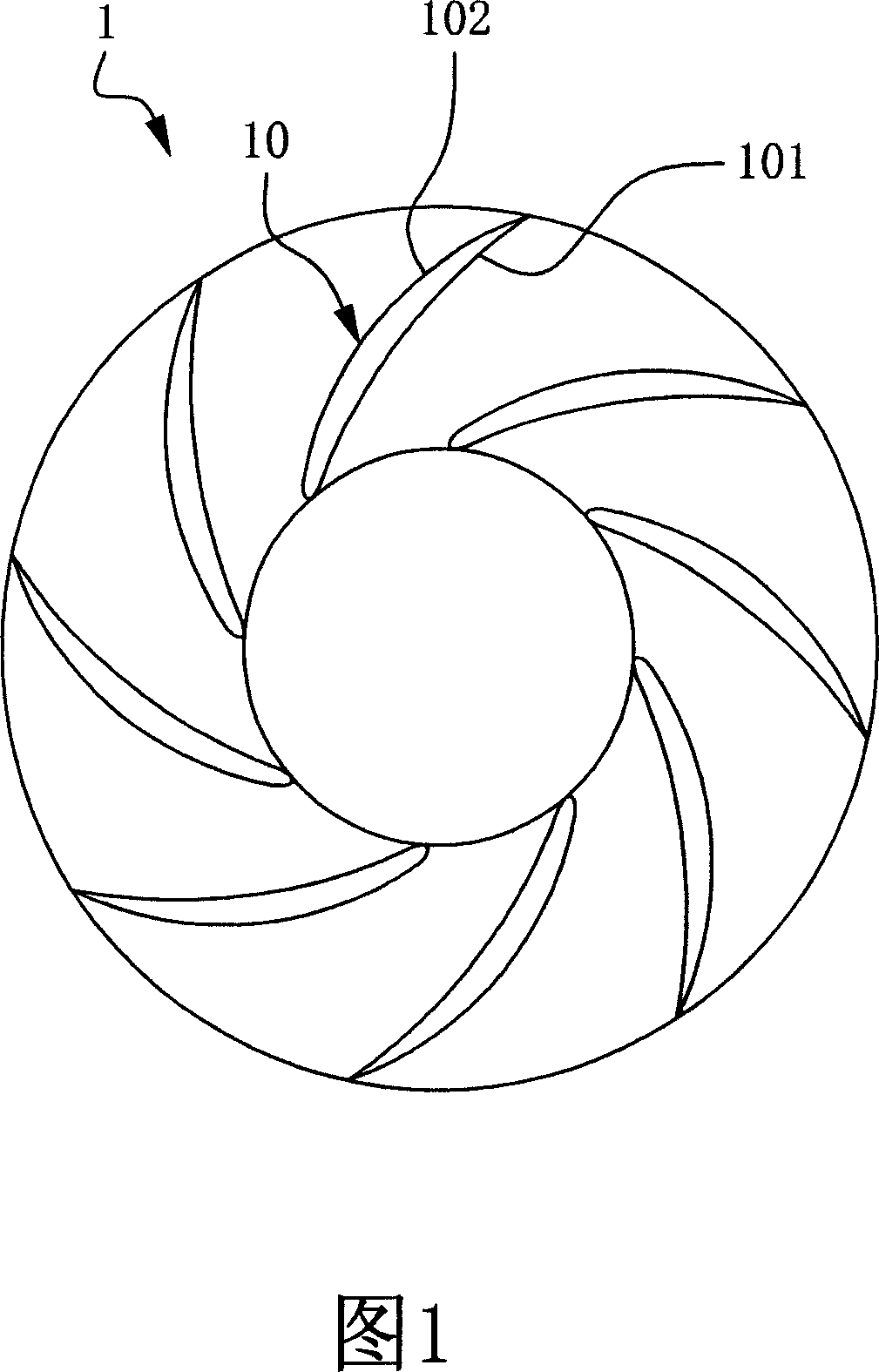

Blade wheel structure and centrifugal fan device using the same

A technology of centrifugal fan and blade structure, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve problems such as high difficulty, complex structure, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the features, purposes and functions of the present invention, the following will describe the relevant detailed structure and design concept of the present invention, so as to understand the characteristics of the present invention, and the detailed description is as follows.

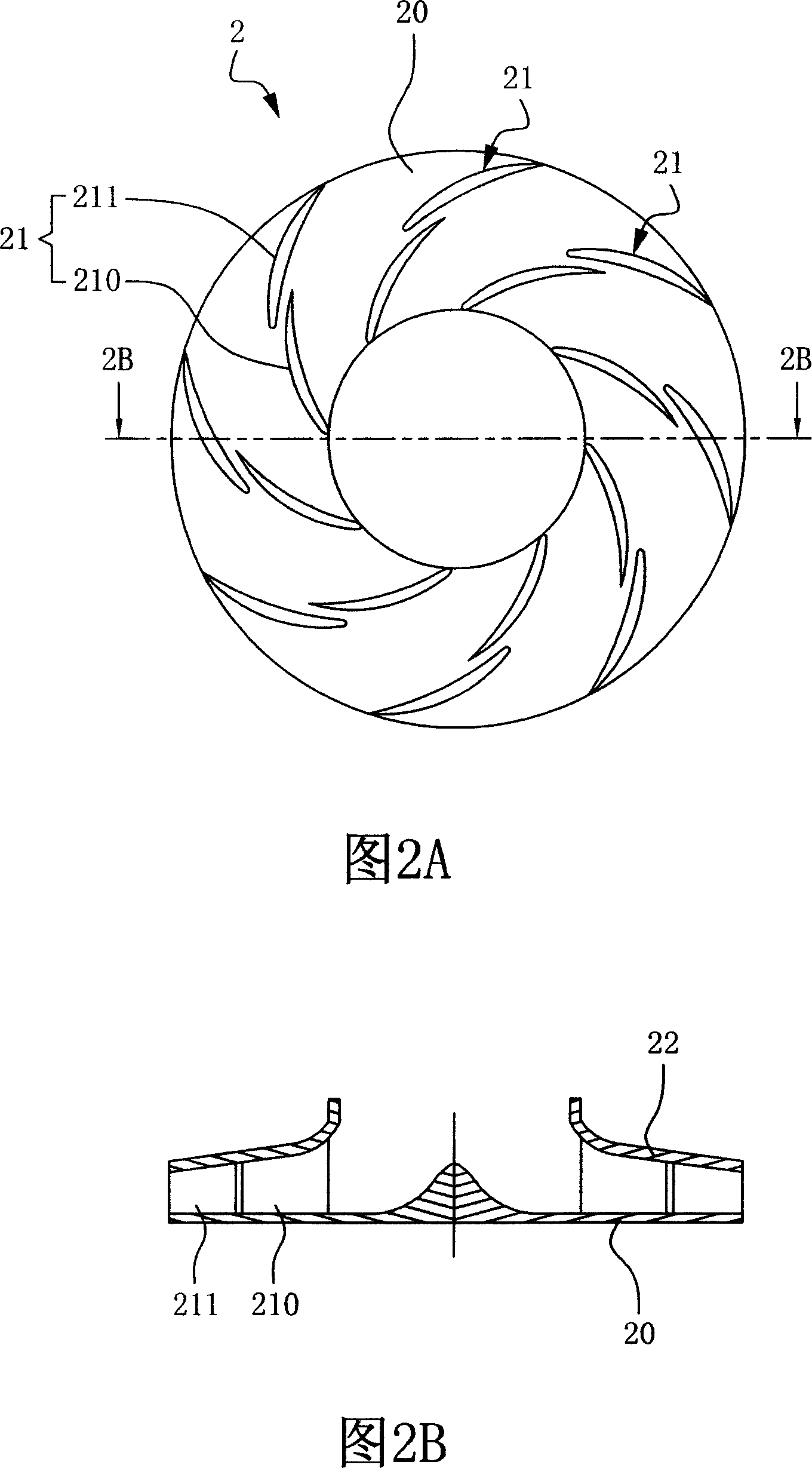

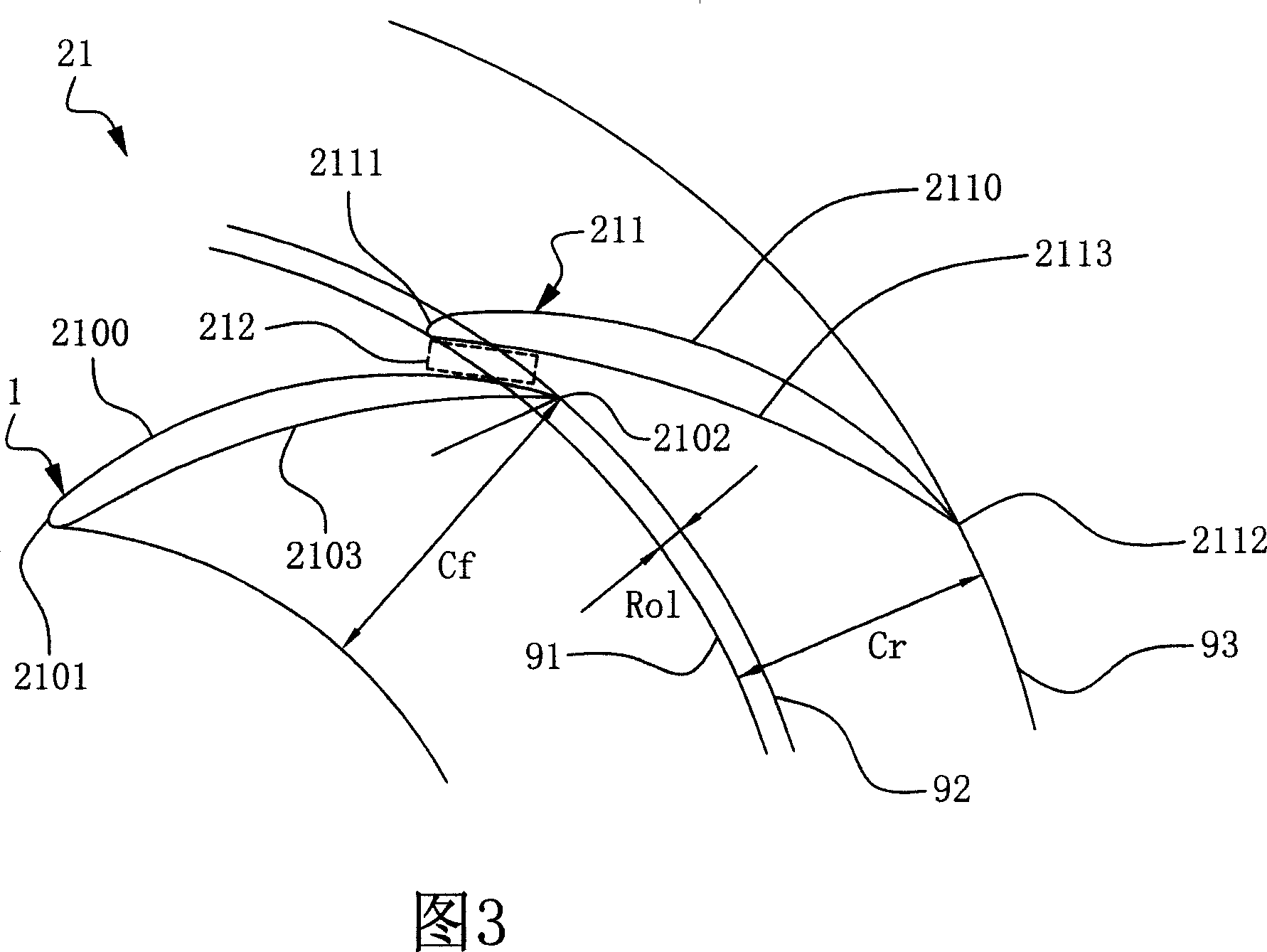

[0021] Please refer to FIG. 2A and FIG. 2B , which are top and cross-sectional schematic diagrams of a preferred embodiment of the impeller structure of the present invention. The impeller structure 2 includes: a disc body 20 ; and multiple pairs of blade structures 21 . The plurality of pairs of blade structures 21 are arranged on the disc body 20, and a front cover 22 is used to connect the plurality of blade structures 21. The blade structure 21 further includes: a first blade 210 and a second blade 210. Blade 211. The second vane 211 is disposed on one side of the first vane 210 , the second vane 211 and the first vane 210 have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com