Relay pressurizing method and device for long distance pipeline transport solid/liquid mixture

A technology of solid-liquid mixture and pipeline transportation, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc. It can solve the problems of uneven solid-liquid ratio, high solid content, line speed change, etc., and achieve good kinetic energy transfer effect , high economic benefit, and small flow pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

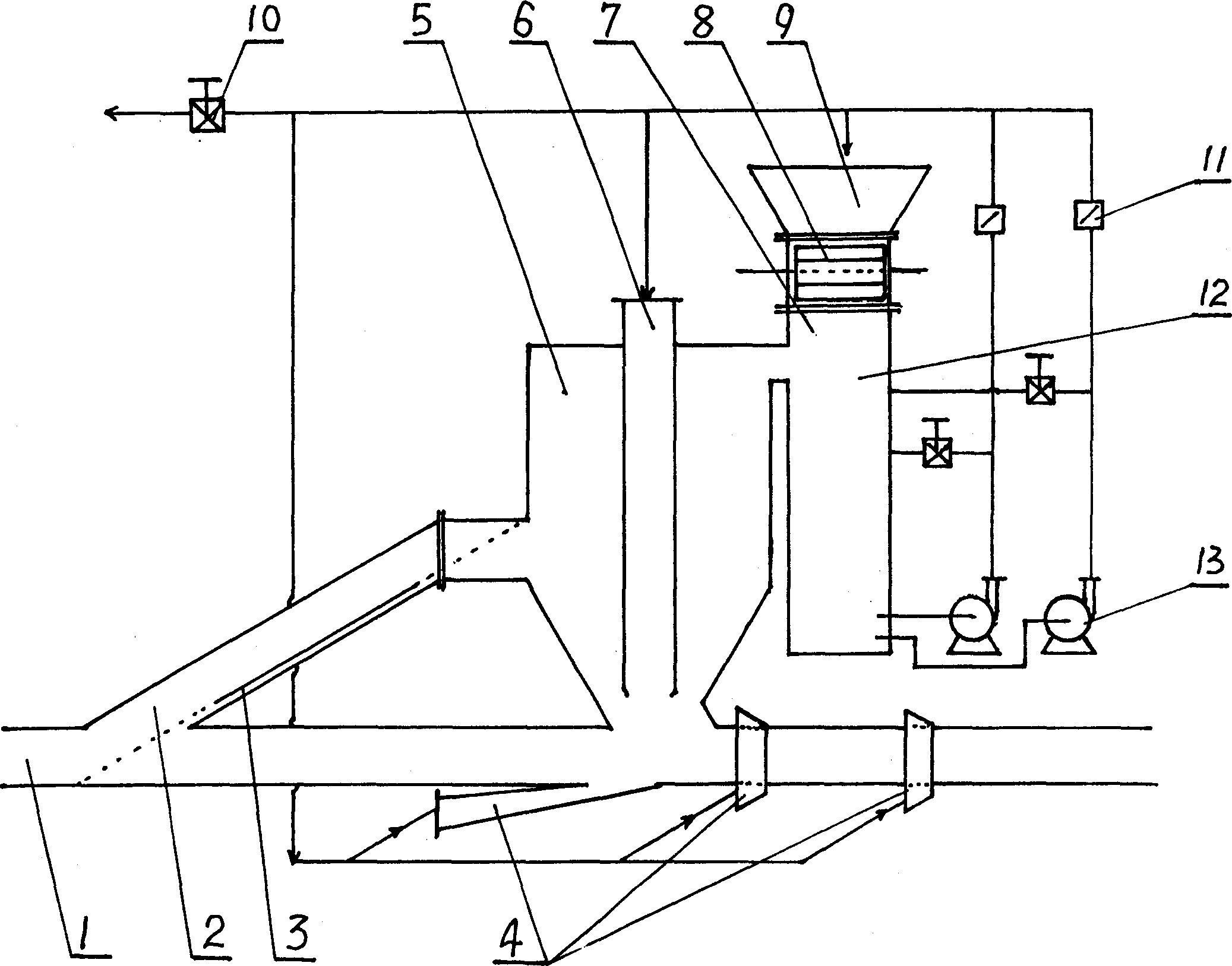

[0028] In order to facilitate a clear and complete understanding of the present invention, the structure and working principle of the relay pressurization device are firstly described below, and then the relay pressurization method is discussed.

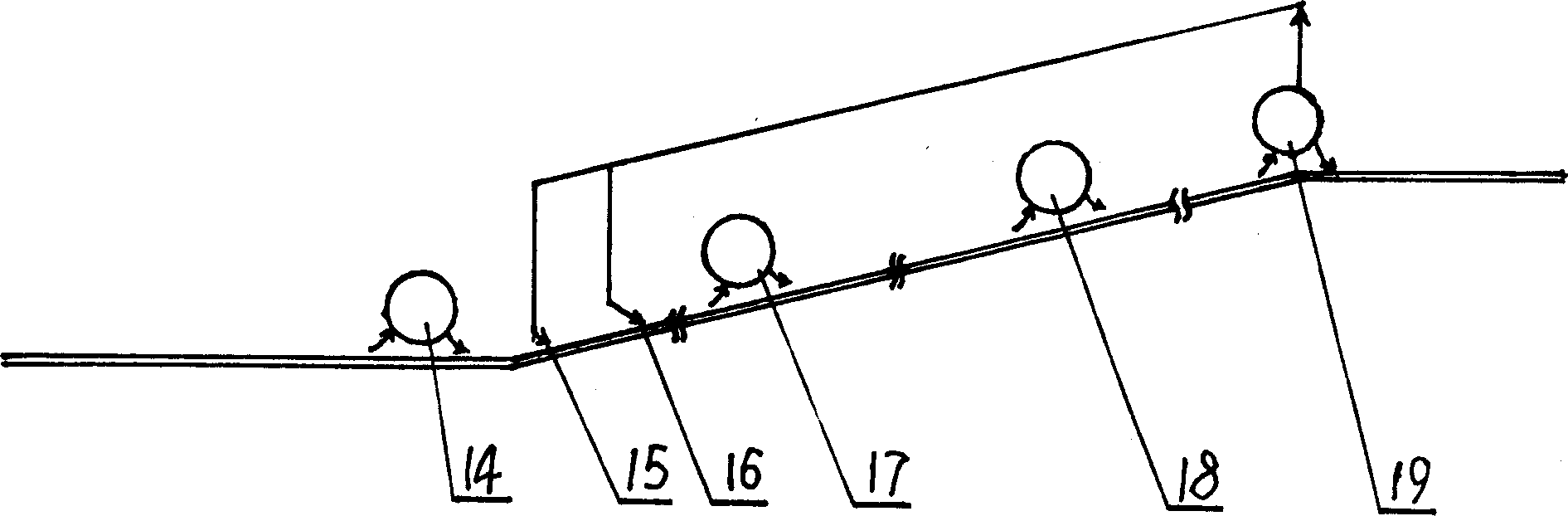

[0029] attached figure 1 Shown is relay pressurization at one relay pressurization station, attached figure 2 It is called a point pressurization station.

[0030] figure 1 Among them, an opening is opened on the delivery pipe 1, and a series-parallel inlet pipe 2 of a solid-liquid separator 5 is connected in parallel, and a fluid channel is formed by the series-parallel inlet pipe 2 and the solid-liquid separator 5. Make the solid-liquid mixture diversion of conveying pipeline 1 enter the method for solid-liquid separator 5 from series-parallel inlet pipe 2 and have multiple, as setting flashboard respectively on conveying pipeline 1 and series-parallel inlet pipe 2, the present invention preferably in series-parallel The inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com