Reactor for mineralization fixation of carbon dioxide by fortified calcium-base solid wastes in ammonia medium system and application method thereof

A carbon dioxide and reactor technology, applied in chemical instruments and methods, calcium carbonate/strontium/barium, chemical/physical processes, etc., can solve the problems of difficult sealing, large kinetic energy consumption, easy deposition of solid materials, etc., to reduce energy Consumption, increase utilization, increase conversion rate and effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

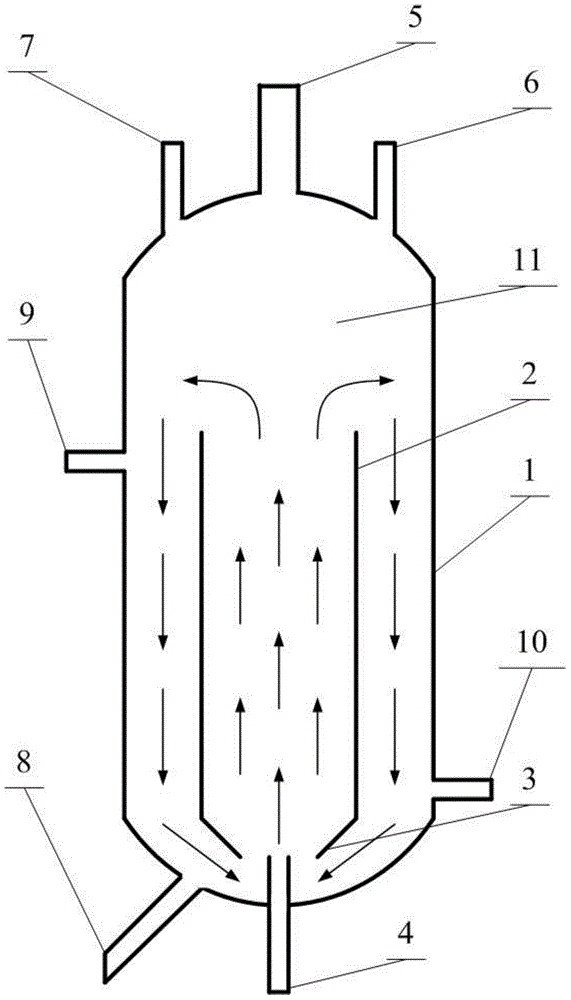

[0034] The size of the pressurized loop reactor is as follows: the height-to-diameter ratio of the guide tube (2) in the pressurized loop reactor (1) is 20:1, and the cross-sectional area of the pressurized loop reactor (1) and the flow guide The ratio of the cross-sectional area of the tube (2) is 1:0.2, the cone angle of the lower end of the guide tube (2) is 30 degrees, and the ratio of the cross-sectional area of the lower end of the guide tube (2) (3) is 1:0.3.

[0035] Operation method: Stir and mix the phosphogypsum particles with a certain particle size and a certain concentration of ammonium carbonate aqueous solution obtained after pretreatment, and continuously inject them into the pressurized loop reactor (1) through the feed port (8). ℃ temperature and the gas inlet (4) through the gas inlet (4) continuously into the pressure of 40bar containing CO 2 gas, in which CO 2 The content is 20%, and the enhanced carbonation reaction is carried out. The product af...

Embodiment 2

[0038] The size of the pressurized loop reactor is as follows: the height-to-diameter ratio of the guide tube (2) in the pressurized loop reactor (1) is 2:1, and the cross-sectional area of the pressurized loop reactor (1) is related to the flow guide The ratio of the cross-sectional area of the tube (2) is 1:0.8, the cone angle of the lower end of the diversion tube (2) (3) is 150 degrees, and the ratio of the cross-sectional area of the lower end of the diversion tube (2) (3) is 1:0.8.

[0039] Operation method: Stir and mix the phosphogypsum particles with a certain particle size and a certain concentration of ammonium carbonate aqueous solution obtained after pretreatment, and continuously inject them into the pressurized loop reactor (1) through the feed port (8). ℃ temperature and the gas inlet (4) through the gas inlet (4) continuously into the pressure of 1bar containing CO 2 gas, in which CO 2 The content is 99.99%, and the enhanced carbonation reaction is car...

Embodiment 3

[0042] The size of the pressurized loop reactor is as follows: the height-to-diameter ratio of the guide cylinder (2) in the pressurized loop reactor (1) is 10:1, and the cylinder cross-sectional area of the pressurized loop reactor (1) The ratio of the cross-sectional area of the tube (2) is 1:0.5, the cone angle of the lower end of the diversion tube (2) (3) is 90 degrees, and the ratio of the cross-sectional area of the lower end of the diversion tube (2) (3) is 1:0.5.

[0043] Operation method: Stir and mix the phosphogypsum particles with a certain particle size and a certain concentration of ammonium carbonate aqueous solution obtained after pretreatment, and continuously inject them into the pressurized loop reactor (1) through the feed port (8). ℃ temperature and the gas inlet (4) through the gas inlet (4) continuously into the pressure of 10bar containing CO 2 gas, in which CO 2 The content is 99.99%, and the enhanced carbonation reaction is carried out. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com