TSV wafer surface polishing method

A surface polishing and wafer technology, applied in grinding devices, electrical components, grinding machine tools, etc., can solve the problems of high price of chemical mechanical polishing machines, inability to guarantee stable and uniform quality, long polishing time, etc. Surface quality, low cost, effect of improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This preferred embodiment is used to remove metal Cu and Ta on the surface of the TSV blind hole electroplating wafer. The thickness of the Cu layer is 15 μm, and the thickness of the Ta layer is 100 nm. After polishing, the depression at the blind hole on the wafer surface is less than 2 μm. Concrete implementation steps according to the present invention are as follows:

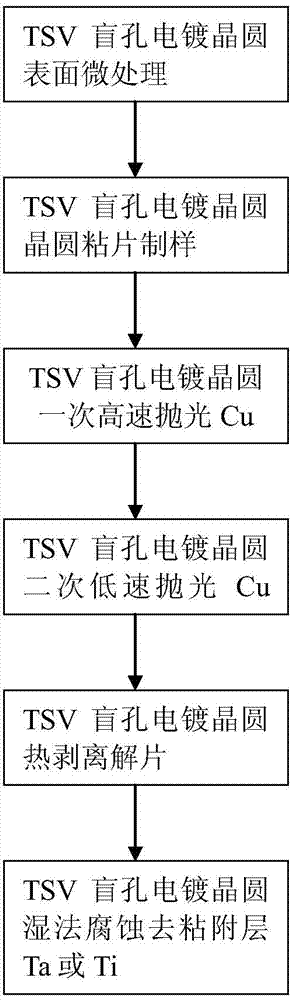

[0034] For the entire process, see figure 1 .

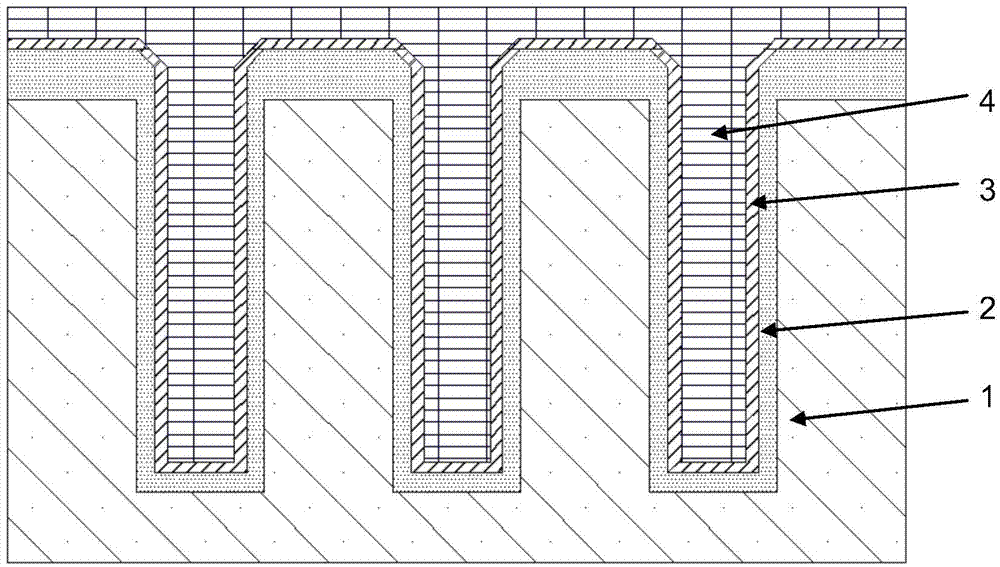

[0035] 1. First, surface treatment is performed on the surface of the TSV blind via plating wafer, see figure 2 , using H 2 SO 4 Solution and hydrogen peroxide mixed solution corrode thick Cu;

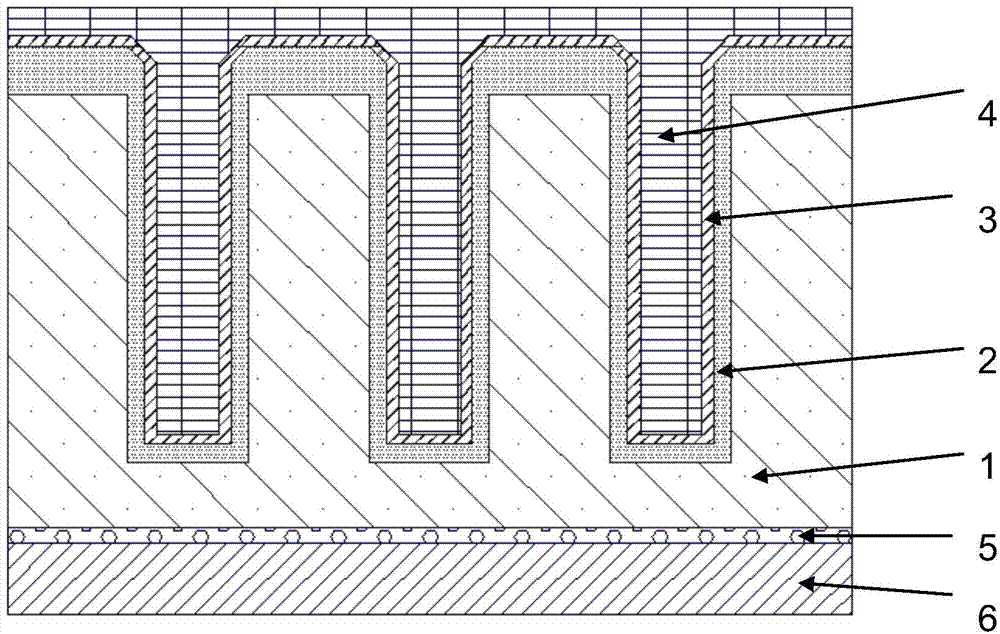

[0036] 2. Next, the wafer sample preparation process is carried out, and the wafer is bonded to the ceramic plate with a heat-peelable double-sided tape. See image 3 , and then the whole is placed on the rotating disc attached with the polishing pad;

[0037] 3. Put pressure on the ceramic disk, use metal Cu polishing liquid, adjust the speed of the cera...

Embodiment 2

[0048] This embodiment is used to remove metal Cu and Ti on the surface of the TSV blind hole electroplating wafer. The thickness of the Cu layer is 30 μm, and the thickness of the Ti layer is 100 nm. After polishing, the depression at the blind hole on the wafer surface is less than 2 μm. According to the specific implementation steps of the present invention such as Figure 1 to Figure 6 As shown, the steps are as follows.

[0049] Step 1.H 2 SO 4 Corrosion of Cu layer on the surface of TSV blind via electroplating wafer by solution and hydrogen peroxide mixed solution, H 2 SO 4 The solution is concentrated H with a mass fraction of 98% 2 SO 4 Add 3 times the volume of H 2 O diluted, H 2 SO 4 The volume ratio of solution: hydrogen peroxide = 1:2, and the corrosion time is 8 minutes.

[0050] Step 2. Use Nitto 3139# hot-peeling double-sided tape to bond the TSV blind hole electroplating wafer process to prepare samples, the pressure is 0.2Mpa, and the pressure holdin...

Embodiment 3

[0056] This embodiment is used to remove metal Cu and Ti on the surface of the TSV blind hole electroplating wafer. The thickness of the Cu layer is 5 μm, and the thickness of the Ti layer is 100 nm. After polishing, the depression at the blind hole on the wafer surface is less than 2 μm. According to the specific implementation steps of the present invention such as Figure 1 to Figure 6 As shown, the steps are as follows.

[0057] Step 1.H 2 SO 4 Corrosion of Cu layer on the surface of TSV blind via electroplating wafer by solution and hydrogen peroxide mixed solution, H 2 SO 4 The solution is concentrated H with a mass fraction of 98% 2 SO 4 Add 10 times the volume ratio of H 2 O diluted, H 2 SO 4 The volume ratio of solution: hydrogen peroxide = 1:5, and the corrosion time is 6 minutes.

[0058] Step 2. Use Nitto 3139# tape heat-peelable double-sided tape to prepare samples for TSV blind via electroplating wafer process bonding, the pressure is 0.1Mpa, and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com