Chemical mechanical polishing solution

A chemical mechanical and polishing liquid technology, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of limited pH value adjustment ability, equipment corrosion, and low pH value of polishing liquid, so as to reduce the content of organic matter and reduce the cost of equipment Effects of corrosion, wide pH adjustment range

Active Publication Date: 2011-05-11

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF12 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the introduction of organic acids, the pH of the polishing solution is low (usually lower than about 2.7), causing equipment corrosion

Because when the pH value is higher than 2.7, ferric nitrate will be hydrolyzed to form ferric hydroxide precipitate, which will cause the polishing fluid to fail and limit its pH adjustment ability

In terms of environmental protection, due to the addition of organic acids, the organic content (COD) in the polishing waste liquid is increased, which is not conducive to environmental protection

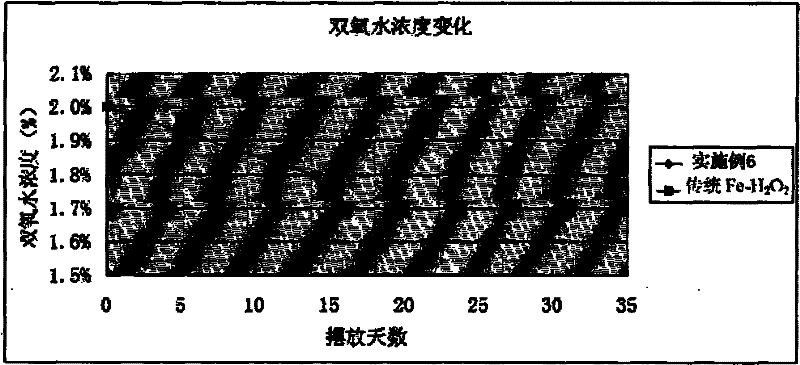

Although organic acid is added as a stabilizer to improve the decomposition rate of hydrogen peroxide, its decomposition rate is still high. Usually, the concentration of hydrogen peroxide will decrease by more than 10% within two weeks, resulting in a decrease in polishing speed and gradual decomposition of the polishing solution.

[0013] Chinese patent CN1966594A discloses a method of adding an etch inhibitor to the above catalytic system, but since the catalyst used is still iron, problems such as easy decomposition of hydrogen peroxide and poor stability still exist

[0018] Among the above-mentioned 3 patents, the combination of silver and hydrogen peroxide (for example, hydrogen peroxide plus silver nitrate) does not have the effect of significantly increasing the polishing speed of tungsten, and only the combination of iron and hydrogen peroxide can significantly improve the polishing speed of tungsten, (the above three The examples of the patent itself demonstrate both of these points)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

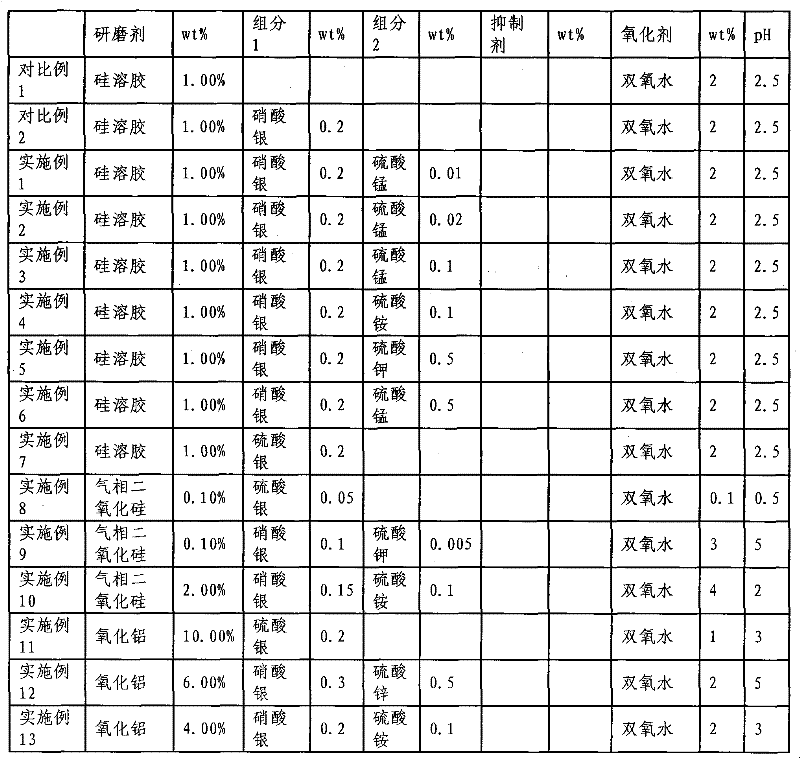

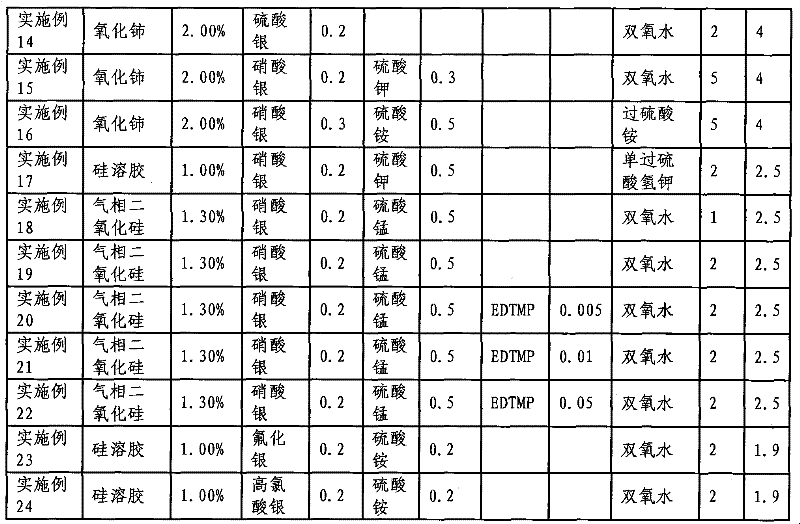

Embodiment 18 and 19

[0053]

[0054] The data in Table 3 are the tungsten polishing rates of the chemical mechanical polishing fluid examples 18 and 19 of the present invention on industrial machines. The result shows that the chemical mechanical polishing fluid of the present invention can realize very high polishing speed on industrial equipment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Description

technical field [0001] The invention relates to a chemical mechanical polishing liquid, in particular to a chemical mechanical polishing liquid containing an activator and a strong oxidizing agent precursor. The present invention further relates to using the chemical mechanical polishing liquid described in the present invention in tungsten chemical mechanical polishing. Background technique [0002] With the continuous development of semiconductor technology and the continuous increase of interconnection layers in large-scale integrated circuits, the planarization technology of conductive layers and insulating dielectric layers has become particularly critical. In the 1980s, the chemical mechanical polishing (CMP) technology pioneered by IBM is considered to be the most effective method for global planarization. [0003] Chemical Mechanical Polishing (CMP) consists of chemical action, mechanical action, and a combination of both. It usually consists of a grinding table wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02C23F3/04

Inventor 王晨何华锋

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com