Chemical mechanical polishing solution

A chemical mechanical and polishing liquid technology, which is applied in the fields of polishing compositions containing abrasives, electrical components, semiconductor/solid-state devices, etc., can solve problems such as decomposition failure, difficulty in removal, unstable oxidant, etc., and achieve high polishing speed, The effect of maintaining a stable removal rate and increasing the polishing speed

Active Publication Date: 2012-04-04

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF17 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if an oxidizing agent is added, such as hydrogen peroxide, the hydrogen peroxide will oxidize the surface of the elemental silicon into silicon dioxide, whic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

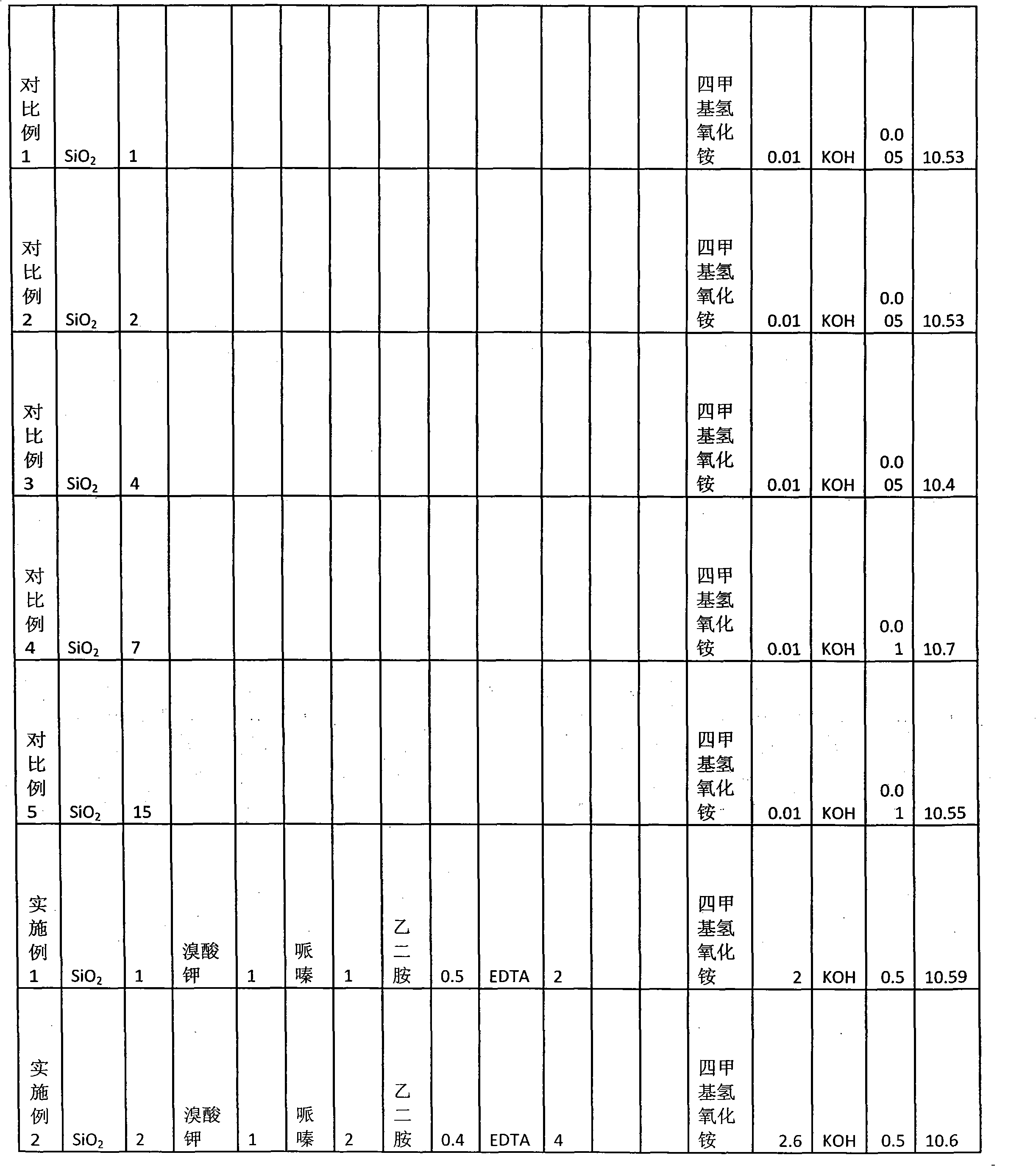

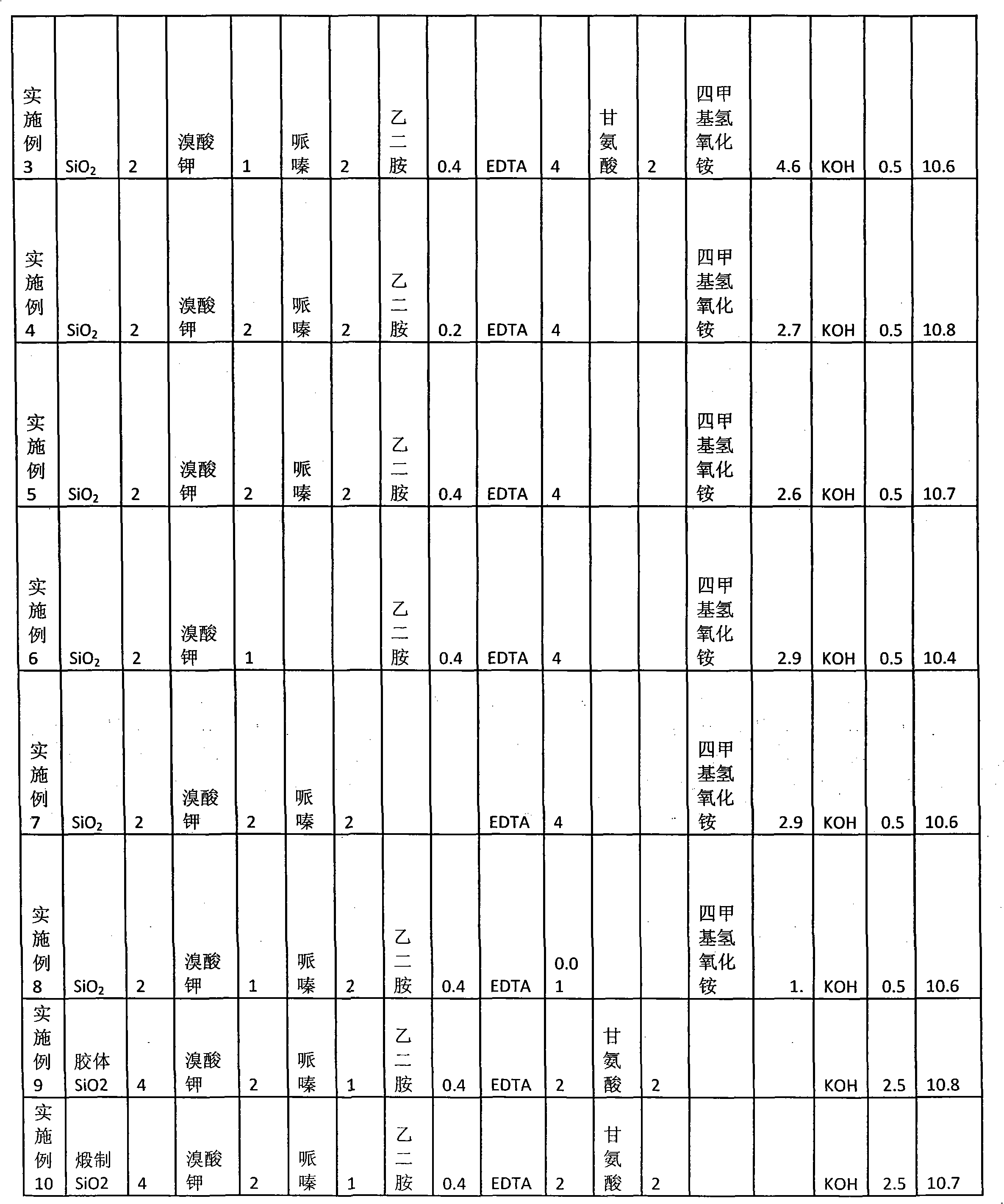

The invention relates to a chemical mechanical polishing solution. The chemical mechanical polishing solution simultaneously contains grinding granules, halogen-containing oxidant, organic amine, ethylene diamine tetraacetic acid (EDTA) and pH regulator; and the chemical mechanical polishing solution has alkali pH value. The polishing solution has very high polishing rate for silicon and copper under the alkali polishing environment. Amino acid can be continuously added into the polishing solution, so that the removal rate of the silicon and the copper is kept stable.

Description

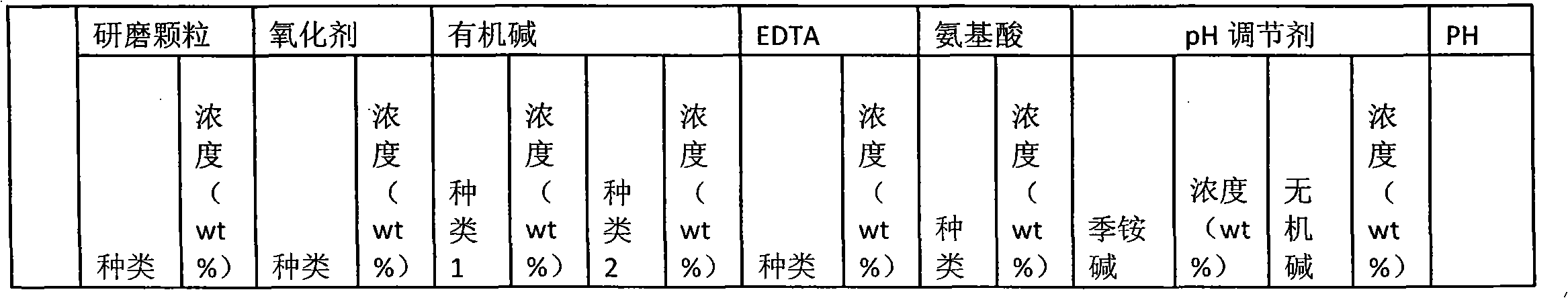

technical field [0001] The invention relates to a chemical mechanical polishing liquid. Background technique [0002] TSV technology (Through-Silicon-Via) is the latest technology to realize the interconnection between chips by making vertical conduction between chips and between wafers. Different from the previous IC package bonding and overlay technology using bumps, the advantage of TSV is that it can maximize the density of chips stacked in three dimensions, minimize the overall size, shorten the interconnection, and improve the performance of chip speed and low power consumption. [0003] When the crystal back thinning technology (backside thinning) in TSV technology requires polishing, it has a very high polishing speed for both silicon and copper materials. [0004] The polishing of silicon is usually carried out under alkaline conditions, which can obtain a higher polishing speed. For example: [0005] US2002032987 discloses a polishing solution using alkanolamine...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09G1/02C23F3/04

CPCC09G1/02H01L21/3212

Inventor 何华锋王晨

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com