Chemical polishing solution for cast aluminium alloy and polishing technology

A casting aluminum alloy and chemical polishing technology, which is applied in the field of casting aluminum alloy chemical polishing liquid and polishing technology, can solve the problems of many electrolytic polishing and difficult to find electrolytic polishing parameters, etc., and achieve high polishing finish, good polishing effect and high polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare cast aluminum alloy polishing liquid A, in 1 liter of volume, polishing liquid A is made up of the raw material of following weight ratio:

[0035] Concentration of 65% nitric acid 600mL

[0036] Concentration of 40% hydrofluoric acid 200mL

[0037] Distilled water 200mL

[0038] Preparation method: (1) Use a graduated cylinder accurate to 0.1ml to measure distilled water and pour it into a beaker for use; (2) Use a graduated cylinder accurate to 0.1ml to measure the required amount of nitric acid and pour it into the beaker of the above step (1) for use (3) adopt the measuring cylinder accurate to 0.1ml to measure the required amount of hydrofluoric acid and pour it into the beaker of the above-mentioned steps (2), and both mix evenly.

[0039] Preparation of polishing solution B:

[0040] Based on a volume of 1 liter, the polishing solution B is composed of the following raw materials in the weight ratio:

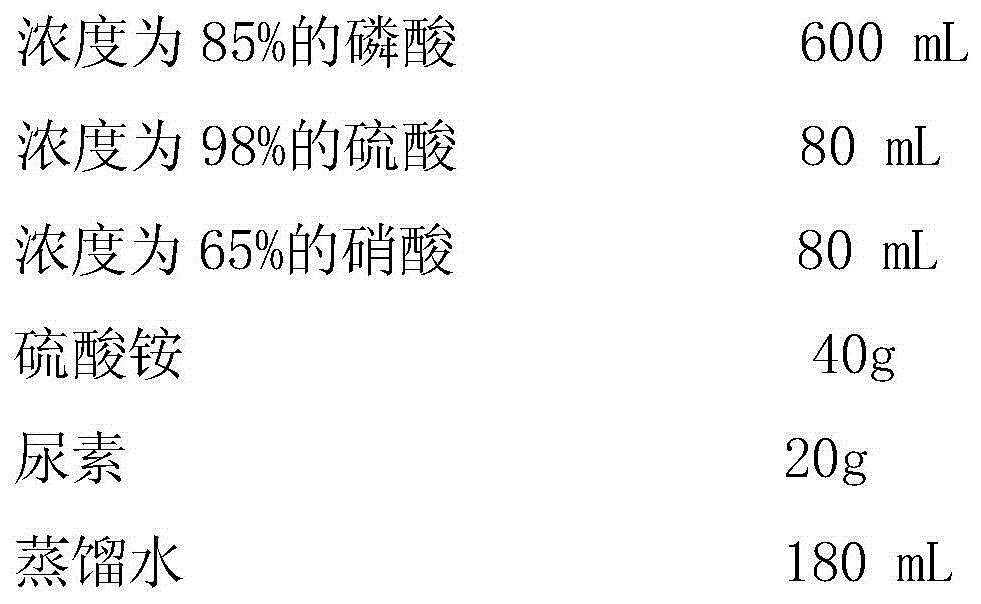

[0041]

[0042] The preparation method compris...

Embodiment 2

[0055] A kind of casting aluminum alloy polishing fluid A, in volume 1 liter, polishing fluid A is made up of the raw material of following weight ratio:

[0056] Concentration of 65% nitric acid 675mL

[0057] 40% hydrofluoric acid 225mL

[0058] Distilled water 100mL

[0059] Preparation method: (1) use a measuring cylinder accurate to 0.1ml to measure distilled water and pour it into a beaker for use; (2) adopt a measuring cylinder accurate to 0.1ml to measure nitric acid and pour it into the beaker of the above step (1) for use; (3) ) Use a graduated cylinder accurate to 0.1ml to measure hydrofluoric acid and pour it into the beaker of the above step (2), and mix well.

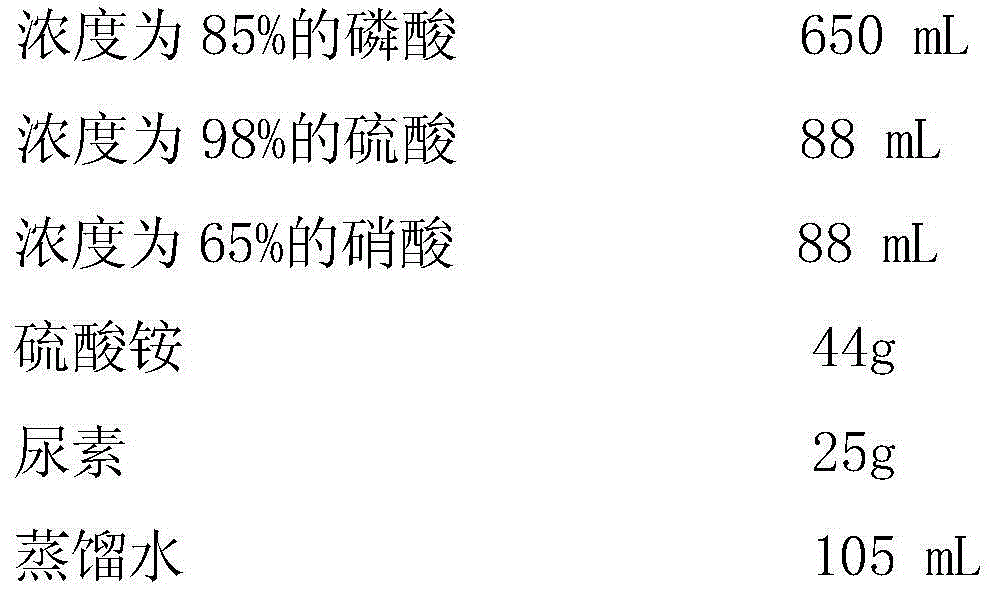

[0060] Based on a volume of 1 liter, the polishing solution B is composed of the following raw materials in the weight ratio:

[0061]

[0062] The preparation method comprises the following steps:

[0063] (1) Use a graduated cylinder accurate to 0.1ml to measure distilled water and pour it into a be...

Embodiment 3

[0076] A kind of casting aluminum alloy polishing fluid A, in volume 1 liter, polishing fluid A is made up of the raw material of following weight ratio:

[0077] 750mL of 65% nitric acid

[0078] Concentration of 40% hydrofluoric acid 250mL

[0079] Distilled water 0mL

[0080] Preparation method: (1) use a measuring cylinder accurate to 0.1ml to measure distilled water and pour it into a beaker for use; (2) adopt a measuring cylinder accurate to 0.1ml to measure nitric acid and pour it into the beaker of the above step (1) for use; (3) ) Use a graduated cylinder accurate to 0.1ml to measure hydrofluoric acid and pour it into the beaker of the above step (2), and mix well.

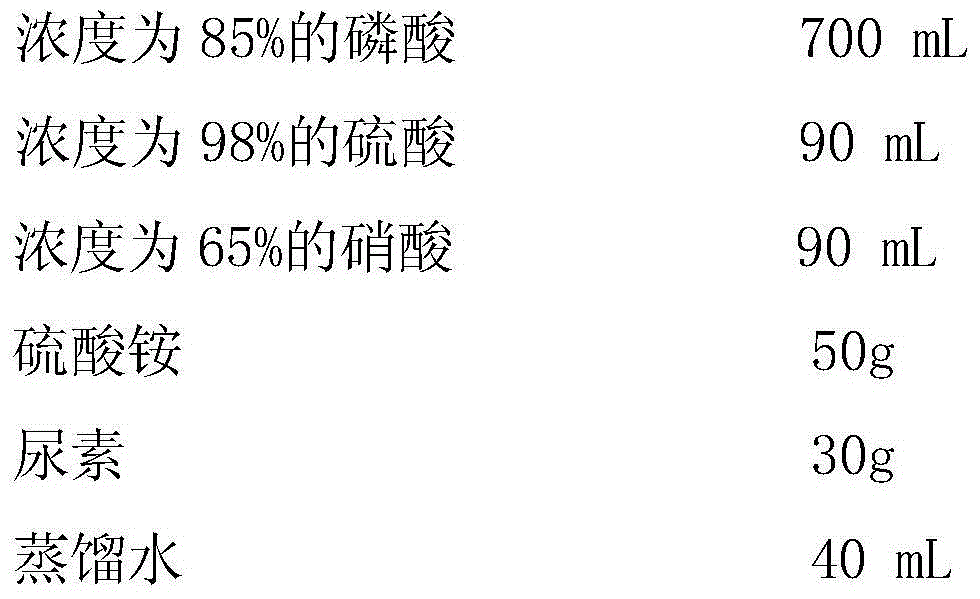

[0081] Based on a volume of 1 liter, the polishing solution B is composed of the following raw materials in the weight ratio:

[0082]

[0083] The preparation method comprises the following steps:

[0084] (1) Use a graduated cylinder accurate to 0.1ml to measure distilled water and pour it into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com