Adjustable four-surface polishing machine for board

An adjustable polishing machine technology, which is applied in the field of polishing machines, can solve the problems of incomplete polishing of plates, affect production efficiency, and small application range, and achieve the effect of increasing the scope of use, increasing the polishing speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

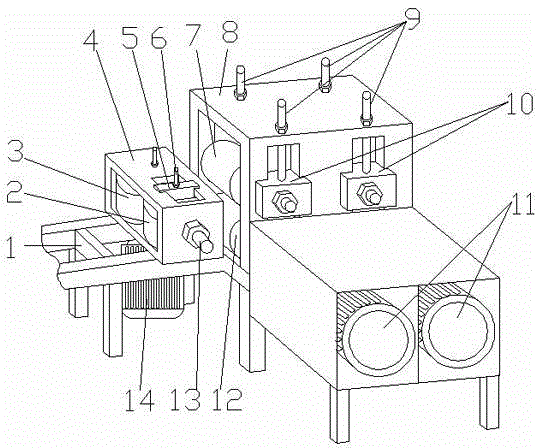

[0023] Such as figure 1 As shown, a four-sided adjustable polishing machine for plates includes a frame 1 and a first polishing box 4 and a second polishing box 8 arranged in parallel on the frame 1, and the first polishing box 4 is vertically arranged There are the same first vertical polishing roller 2 and the second vertical polishing roller 3, and the first vertical polishing roller 2 is fixed in the first polishing box 4 and connected with the vertical polishing roller located at the lower end of the frame 1 The straight polishing roller driving motor 14 is connected, and the bearings 6 at the two ends of the second vertical polishing roller 3 are respectively connected with the first bearing moving seat 5 of "H" shape, and the first bearing moving seat 5 is connected with the first bearing moving seat 5 located on the The second screw rod 13 on the side of the first polishing case 4 is fixedly connected, and the second screw rod 13 is fixed by a nut after passing throug...

Embodiment 2

[0027] With embodiment 1, the difference is that two groups of parallel and identical first vertical polishing rollers 2 and second vertical polishing rollers 3 are arranged in the first polishing box 4, and in the second polishing box 8 There are three sets of identical and parallel first horizontal polishing rollers 7 and second horizontal polishing rollers 12, which can greatly improve the polishing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com