Preparation method of sapphire polishing solution

A technology of polishing liquid and sapphire, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as the difficulty in controlling the size of primary particles and secondary particles of alumina polishing liquid, and achieve high phase concentration, good suspension, and polishing defects. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

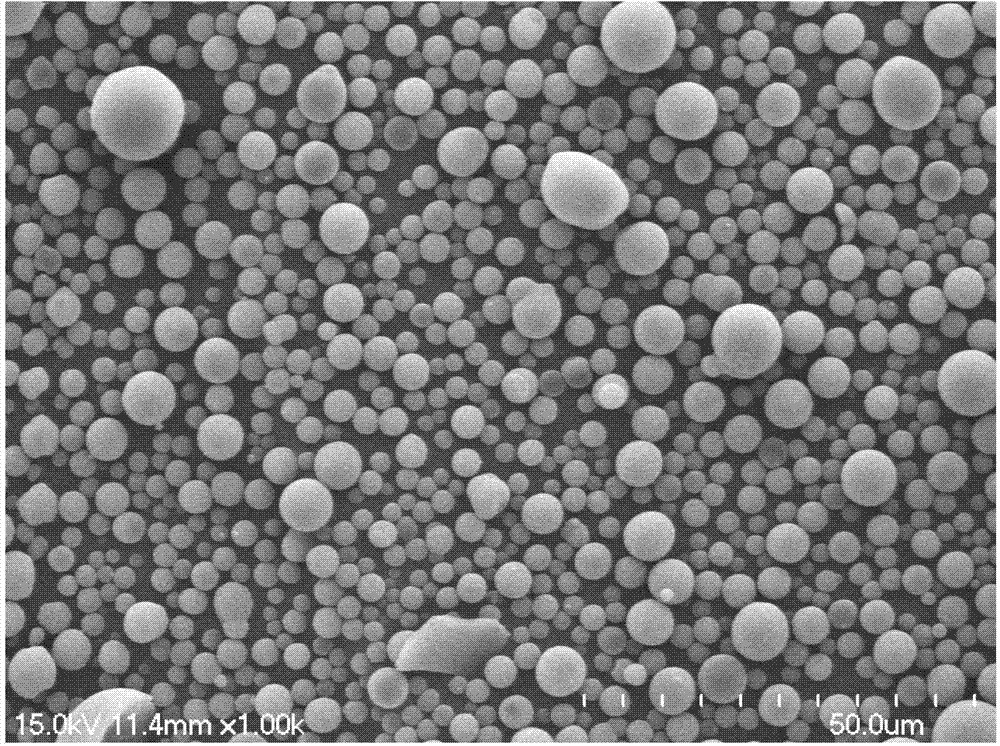

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 sapphire polishing liquid

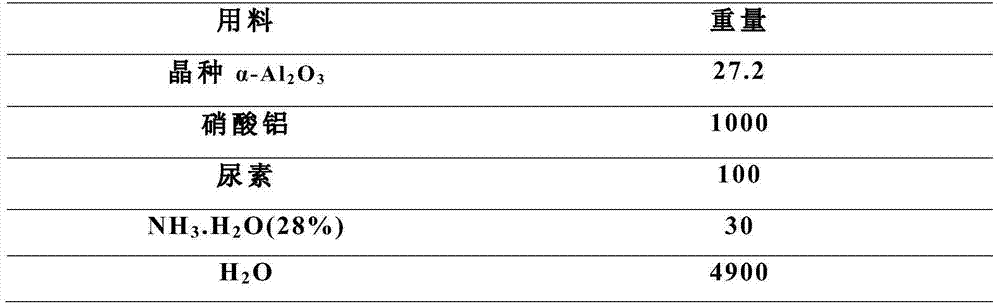

[0050] Material formula

[0051]

[0052] Preparation steps:

[0053] (1) Nano α-Al 2 o3 (average particle size 100nm) aqueous dispersion (pH 4.0) was diluted with pure water to 25%wt aqueous dispersion, ultrasonicated or stirred evenly, used as seeds.

[0054] (2) Aluminum nitrate [Al(NO 3 ) 3 .9H 2 O] was dissolved in pure water to prepare an aluminum-containing solution with a concentration of 2mol / L, and urea was added to the aluminum nitrate solution to obtain an aluminum nitrate hydrolyzate.

[0055] (3) Based on alumina calculation, according to the alumina content ratio of 5:100, add the seeds into the aluminum-containing reaction solution, and stir vigorously to form a uniform aluminum-containing dispersion mixed solution.

[0056] (4) Spray-dry the aluminum-containing dispersion mixed solution at 200-220° C. to obtain a precursor of nano-alumina powder.

[0057] (5) Put the obtained precurso...

Embodiment 2

[0063] The preparation of embodiment 2 sapphire polishing liquid

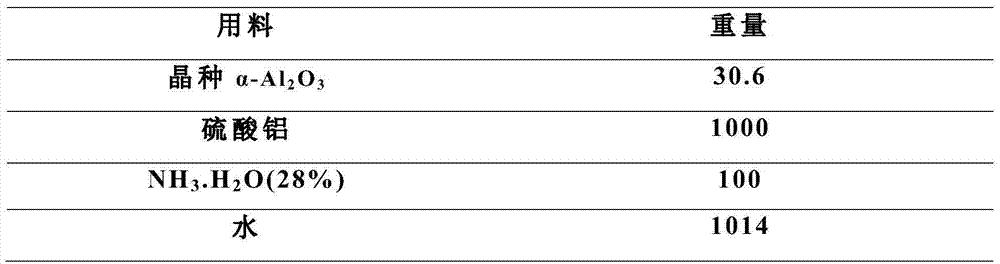

[0064] Material formula

[0065]

[0066] Preparation steps:

[0067] (1) Nano α-Al 2 o 3 (average particle size 100nm) aqueous dispersion (pH 4.0) was diluted with pure water to 25%wt aqueous dispersion, ultrasonicated or stirred evenly, used as seeds.

[0068] (2) Aluminum sulfate [Al 2 (SO 4 ) 3 .18H 2 O] was dissolved in pure water to prepare an aluminum-containing reaction solution with a concentration of 1 mol / L.

[0069] (3) Based on alumina calculation, according to the alumina content ratio of 5:100, add the seeds into the aluminum-containing reaction solution, and stir vigorously to form a uniform aluminum-containing dispersion mixed solution.

[0070] (4) Spray-dry the aluminum-containing dispersion mixed solution at 200-220° C. to obtain a precursor of nano-alumina powder.

[0071] (5) Put the obtained precursor into a high-temperature furnace for heat treatment at 1150° C. for 90 minute...

Embodiment 3

[0077] The preparation of embodiment 3 sapphire polishing liquid

[0078] Material formula

[0079]

[0080] Preparation steps:

[0081] (1) Nano α-Al 2 o 3 (average particle size 100nm) aqueous dispersion (pH 4.0) was diluted with pure water to 25%wt aqueous dispersion, ultrasonicated or stirred evenly, used as seeds.

[0082] (2) Aluminum ammonium sulfate [NH 4 Al(SO 4 ) 2 .12H 2 O] was dissolved in pure water to prepare an aluminum-containing reaction solution with a concentration of 0.5 mol / L.

[0083] (3) Based on alumina calculation, according to the alumina content ratio of 5:100, add the seeds into the aluminum-containing reaction solution, and stir vigorously to form a uniform aluminum-containing dispersion mixed solution.

[0084] (4) Spray-dry the aluminum-containing dispersion mixed solution at 200-220° C. to obtain a precursor of nano-alumina powder.

[0085] (5) Put the obtained precursor into a high-temperature furnace for heat treatment at 1200° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com