Resin-bonded diamond abrasive tool, method and mold for producing resin-bonded diamond abrasive tool

A diamond and resin technology, applied in the direction of abrasives, grinding devices, manufacturing tools, etc., can solve the problems of high production cost, no polishing function, and waistline polishing of diamond grinding wheels, and achieve high grinding and polishing efficiency. Simple and reasonable, good grinding and polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

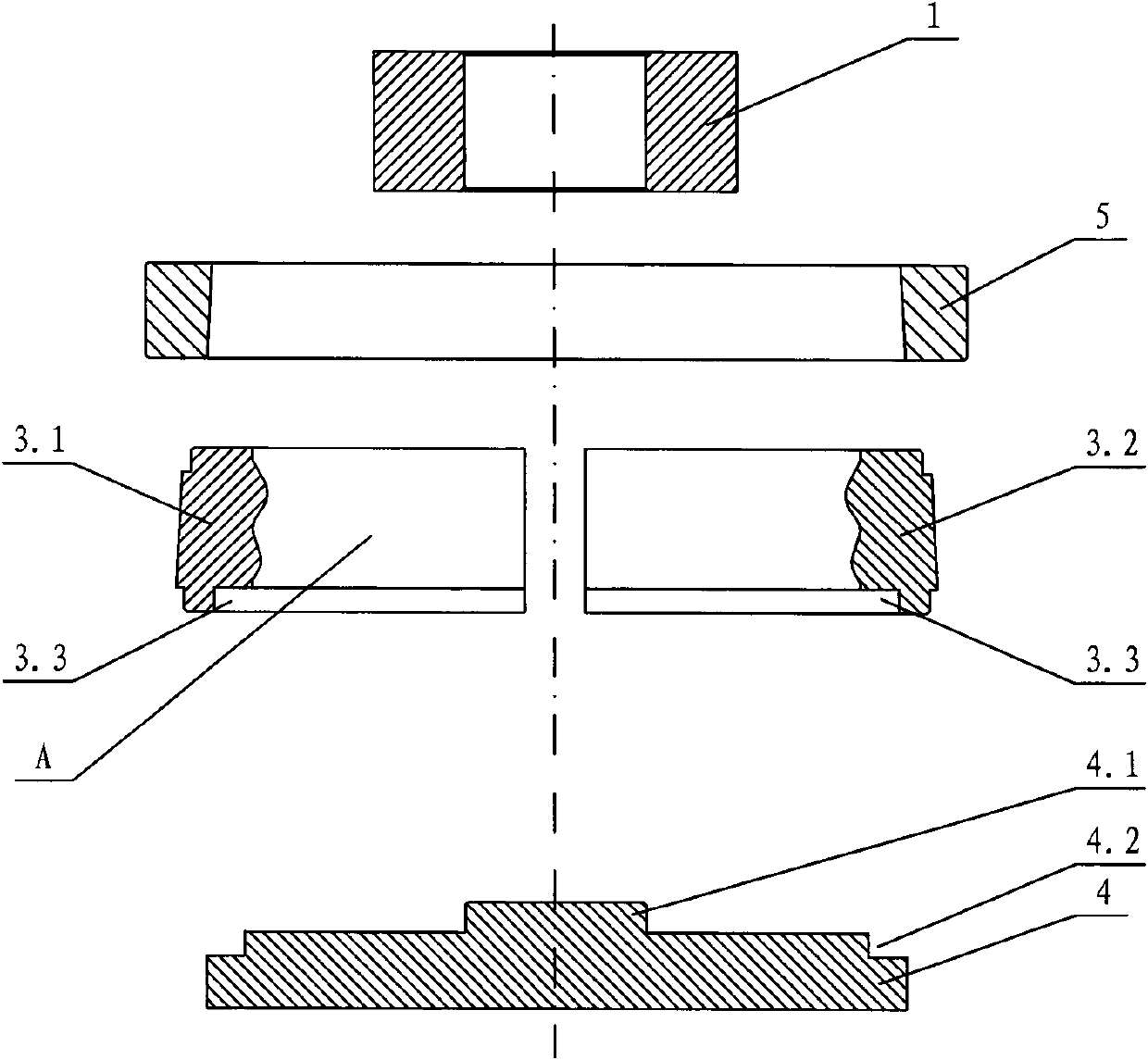

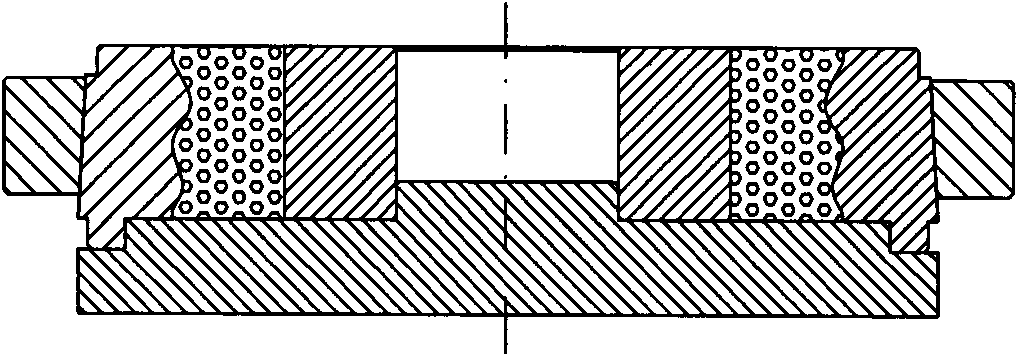

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

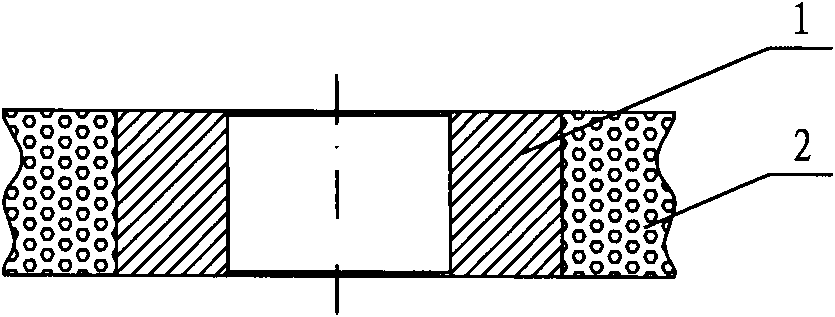

[0028] see Figure 1-Figure 10 , the resin diamond abrasive tool comprises a matrix 1 and an abrasive layer 2, and the abrasive layer 2 is formed by mixing and casting a binder, an abrasive and a filler; wherein, the binder is composed of a phenolic epoxy vinyl ester resin solution, an initiator and a promoter The abrasive material includes diamond and silicon carbide. The weight ratio of the above components is: 100 parts of novolac epoxy vinyl ester resin solution, 2 to 3 parts of initiator, 1 to 4 parts of accelerator, and 10 parts of diamond ~20 parts, silicon carbide 10~30 parts, filler 80~120 parts.

[0029] The filler in this embodiment is any one or a combination of any two or more of alumina powder, quartz powder and cerium oxide polishing powder; the initiator can use ketone peroxide, here methyl ethyl ketone peroxide can be selected; the acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com